Introduction

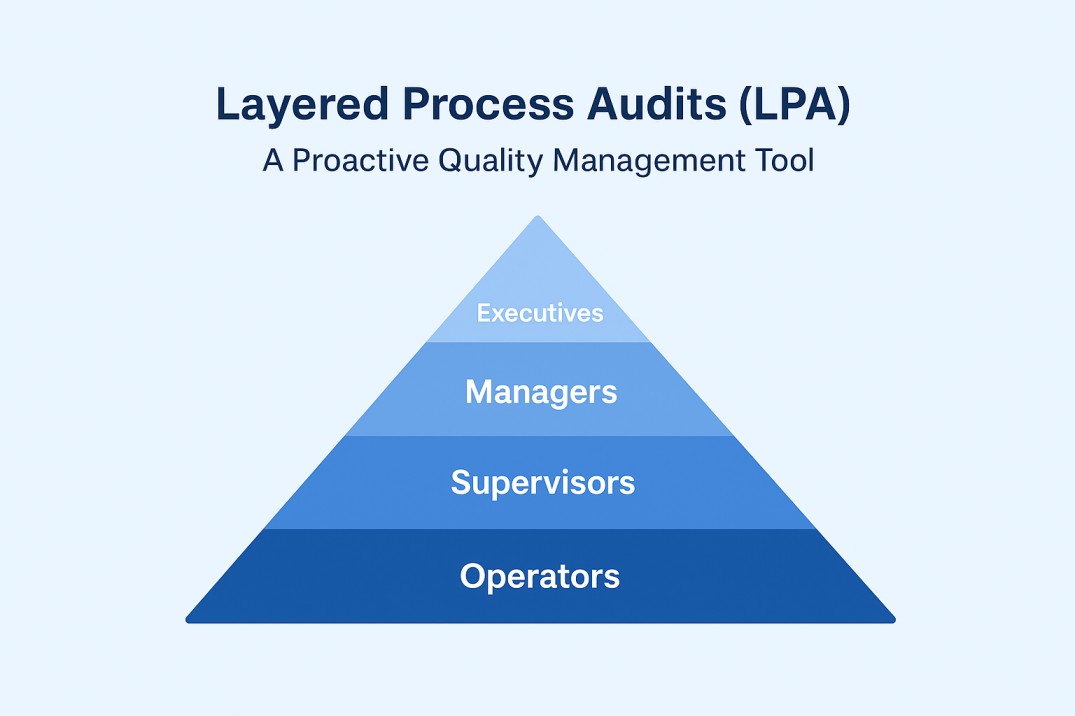

In today’s competitive manufacturing environment, ensuring consistent product quality and process compliance is critical. Traditional audits often occur too late in the process, catching defects only after they have occurred. Layered Process Audit (LPA) addresses this by proactively checking processes at multiple organizational levels, including operators, supervisors, managers, and executives.

What is a Layered Process Audit (LPA)?

A Layered Process Audit (LPA) is a structured, systematic approach used in manufacturing and service environments to ensure that processes are being performed correctly and consistently. It is designed to verify compliance with standards, procedures, and best practices at multiple levels of an organization, rather than relying on a single quality check.

Key Difference from a Normal Process Audit

- Process Audit: Done periodically, usually by quality teams.

- Layered Process Audit: Done frequently by multiple levels of leadership, ensuring accountability at all levels.

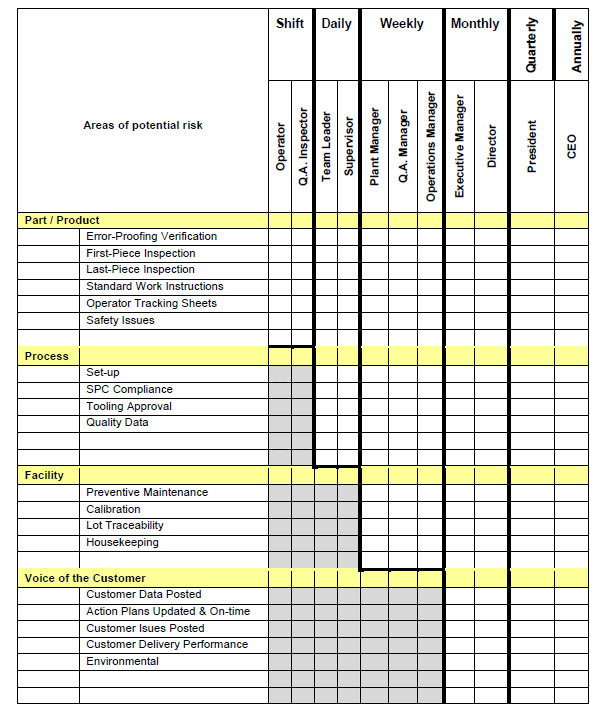

Layers in an LPA

LPAs involve different layers of the organization:

- Operators – conduct quick daily checks.

- Supervisors – perform weekly audits.

- Managers – oversee monthly compliance reviews.

- Executives – ensure quarterly alignment with business goals.

Benefits of LPAs

Implementing LPAs offers several advantages:

- Early detection of process deviations

- Reduction of rework, rejection, and defects

- Better compliance with customer and industry standards

- Strengthened accountability across all levels

- Improves standard work adherence.

- Increases visibility of issues across layers.

- Encourages proactive problem-solving.

Frequency of LPAs

The frequency depends on the audit layer:

- Operators: per shift

- Supervisors: weekly

- Managers: monthly

- Executives: quarterly

How to Implement an Effective LPA Program

- Define objectives (e.g., safety, defect prevention).

- Create short, simple checklists (5–15 minutes).

- Assign audit responsibilities by layer.

- Train auditors for consistency.

- Capture results and follow up with corrective actions.

- Review and refine regularly.

Layered Process Audit Checklist:

LPAs and IATF 16949

While not explicitly mandatory, LPAs are often required by customer-specific requirements under IATF 16949. They help demonstrate process control and compliance with quality standards.

IATF 16949 Clauses and Requirements

Future of LPAs: Digital Tools

Modern factories are replacing paper checklists with digital LPA software. These tools allow:

- Mobile-based audit checklists

- Real-time reporting and dashboards

- Automatic corrective action tracking

- Analytics to identify trends

Common Challenges & Best Practices

- Audit fatigue & pencil-whipping: mitigate through rotating questions and randomizing checklists.

- Inconsistent execution: provide training and standard checks across teams.

- Lack of follow-through on findings: assign accountability, track CAPA, report closure

- Complexity of managing multiple layers: digital workflows and scheduled systems help simplify coordination.

Real-Life Example of Layered Process Audit (LPA) in Action

Let’s take an example from the automotive industry, where LPAs are widely used to comply with IATF 16949 requirements.

A Tier-1 automotive supplier was facing recurring customer complaints due to missing torque on critical bolts in engine assemblies. Traditional final inspections could not always catch the issue because not every unit was checked, and some defects escaped to the customer.

To address this, the company implemented Layered Process Audits (LPAs):

- Operator Layer (daily checks):

Every operator verified torque settings on their workstation at the start of each shift using a calibrated torque wrench. - Supervisor Layer (weekly audits):

Supervisors conducted audits with a short checklist verifying:- Correct torque tool calibration

- Operator following standard work instructions

- Bolts tightened in the specified sequence

- Manager Layer (monthly audits):

Managers reviewed audit records and randomly observed operators performing bolt tightening to ensure both process compliance and checklist effectiveness. - Executive Layer (quarterly audits):

Plant leadership walked the line, confirming adherence to the LPA process and discussing audit findings with supervisors and operators.

Results achieved:

- Defect rate reduced by 60% within three months.

- Customer complaints related to missing torque were eliminated.

- Employees felt more engaged since every layer of the organization was actively involved in maintaining quality.

This example shows how LPAs go beyond inspection—they build accountability at every level, prevent recurring issues, and strengthen the culture of quality.

Frequently Asked Questions (FAQs)

Q1: What is a layered process audit in simple words?

An LPA is a short, frequent audit that checks whether critical processes are followed correctly at multiple organizational levels.

Q2: How many layers are there in an LPA?

Typically, there are three to four layers: operator, supervisor, manager, and executive.

Q3: How often should LPAs be conducted?

Operators should audit daily, supervisors weekly, managers monthly, and executives quarterly.

Q4: Who conducts LPAs?

Everyone from line operators to executives participates, depending on the audit layer.

Q5: Is LPA required for IATF 16949?

While not directly mandatory, many automotive OEMs require it as part of customer-specific requirements.

Q6: What are the benefits of LPAs?

LPAs reduce defects, strengthen accountability, improve compliance, and build a culture of continuous improvement.

Conclusion

Layered Process Audits are more than just a compliance tool—they’re a way to embed quality into everyday processes. By involving all levels of the organization, LPAs foster a culture of accountability and continuous improvement. Whether you are in automotive, aerospace, or general manufacturing, implementing an effective LPA program can significantly enhance your quality management system.

Reference: CQI-8 Layered Process Audit Guidelines

You may also like to read about:

How to perform an Internal audit in the automotive industry?

How to perform a Process audit in the automotive industry?

Thanks for the insights! Thanks for sharing your thoughts.

Great article! I’ll definitely be checking back for more.