How Lean Methodology Identifies Waste in Processes?

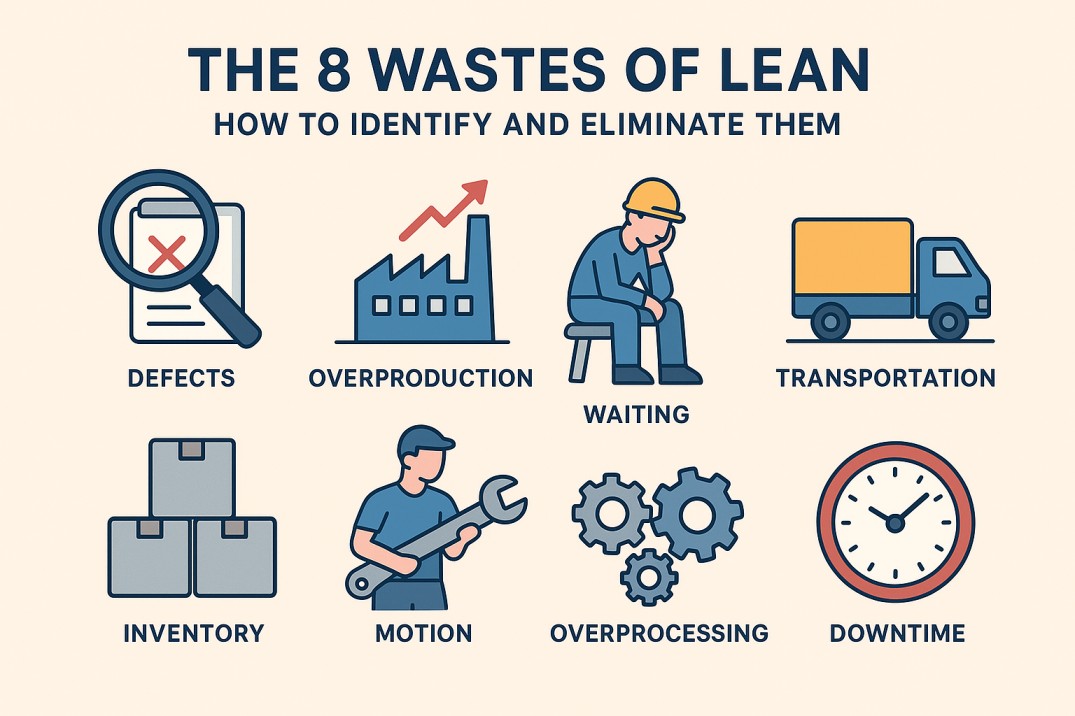

In today’s highly competitive manufacturing and service environment, organizations must deliver maximum value to customers while minimizing costs, delays, and inefficiencies. Lean methodology provides a powerful framework to achieve this by systematically identifying and eliminating waste in processes. Originating from the Toyota Production System (TPS), Lean focuses on creating more value with fewer resources. Understanding … Read more