What Are QMS Principles?

Quality Management System (QMS) principles are fundamental concepts that guide organizations in establishing, implementing, maintaining, and continually improving an effective quality management system.

The ISO 9001 QMS principles provide a structured framework to ensure customer satisfaction, process consistency, and continual improvement. Since IATF 16949 is based on ISO 9001, the 7 QMS principles in IATF 16949 remain the same, but they are applied more rigorously for automotive manufacturing and supply chains.

Understanding these principles is essential for quality managers, auditors, and engineers who want to build a robust system rather than just achieve certification.

- What Are QMS Principles?

- What Are the 7 Principles of QMS?

- 1. Customer Focus

- 2. Leadership

- 3. Engagement of People

- 4. Process Approach

- 5. Improvement

- 6. Evidence-Based Decision Making

- 7. Relationship Management

- ISO 9001 and IATF 16949: Why the Same QMS Principles?

- How QMS Principles Are Used in Audits

- QMS Principles PDF

- Frequently Asked Questions

- Change in QMS Principles in IATF 16949 :

- Benefits of 7 QMS Principles:

- Conclusion

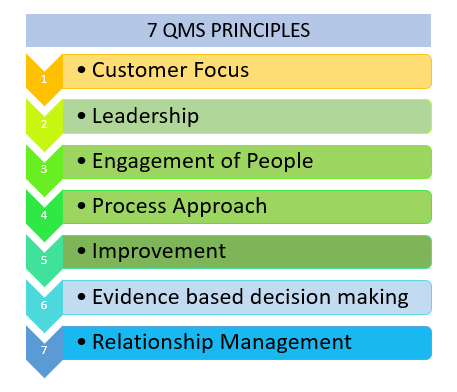

What Are the 7 Principles of QMS?

The internationally accepted 7 principles of QMS used in ISO 9001 and IATF 16949 are:

- Customer Focus

- Leadership

- Engagement of People

- Process Approach

- Improvement

- Evidence-Based Decision Making

- Relationship Management

These principles form the foundation of all ISO-based quality management systems and directly influence compliance, audit performance, and business results.

1. Customer Focus

Customer focus means understanding current and future customer needs, meeting customer requirements, and striving to exceed customer expectations. In IATF 16949, customer focus is especially critical due to OEM-specific requirements and zero-defect expectations.

Organizations applying strong customer focus:

- Monitor customer satisfaction data

- Address complaints and feedback effectively

- Ensure product conformity and on-time delivery

This principle directly impacts customer retention and long-term business success.

2. Leadership

Leadership ensures unity of purpose and direction within the organization. Top management must create an environment where people are fully involved in achieving quality objectives.

Leaders establish unity of purpose and direction of the organization. They should create and maintain an internal environment in which people can become fully involved in achieving the organization’s objectives. It is the top management’s responsibility to give further responsibility to the process owners.

Effective leadership in QMS includes:

- Establishing quality policy and objectives

- Providing resources and support

- Promoting a quality culture across all levels

In audits, leadership commitment is verified through management reviews, objective setting, and visible involvement.

3. Engagement of People

People at all levels are the essence of an organization. Engaged employees contribute to improvement, innovation, and consistent quality output.

Key practices include:

- Skill development and training

- Clear role definitions

- Encouraging participation in problem-solving

IATF 16949 places strong emphasis on competence, awareness, and accountability on the shop floor.

4. Process Approach

The process approach means managing activities as interconnected processes that function as a coherent system. This principle helps organizations achieve consistent and predictable results.

Benefits of the process approach:

- Better control of inputs and outputs

- Reduced variation and waste

- Improved efficiency

In ISO 9001 and IATF 16949 audits, process interaction, KPIs, and risk identification are closely examined.

5. Improvement

Continual improvement is a permanent objective of every quality management system. Organizations must continually enhance performance, products, and processes.

Improvement activities include:

- Corrective actions

- Kaizen

- Preventive actions

- Lean and problem-solving tools

In IATF 16949, improvement is closely linked with defect prevention and risk reduction.

6. Evidence-Based Decision Making

Effective decisions are based on the analysis and evaluation of data. This principle ensures that decisions are objective rather than opinion-based.

Examples of evidence-based decision making:

- Use of KPIs and dashboards

- Analysis of audit results

- Trend monitoring of defects and customer complaints

Auditors expect organizations to demonstrate decisions supported by data.

7. Relationship Management

Organizations depend on suppliers, service providers, and other interested parties. Managing these relationships optimizes performance across the supply chain.

Relationship management involves:

- Supplier evaluation and development

- Clear communication of requirements

- Long-term partnerships

This principle is extremely important in IATF 16949 due to automotive supplier risk and traceability requirements.

ISO 9001 and IATF 16949: Why the Same QMS Principles?

Many professionals ask what are the 7 principles of IATF 16949 and whether they differ from ISO 9001. The answer is simple: both standards use the same quality management principles.

IATF 16949 builds upon ISO 9001 by adding:

- Automotive-specific requirements

- Risk-based thinking

- Defect prevention focus

However, the foundational QMS principles of ISO 9001 remain unchanged.

How QMS Principles Are Used in Audits

During ISO 9001 and IATF 16949 audits, auditors evaluate how effectively the 7 QMS principles are applied in real processes, not just documented procedures.

Auditors typically check:

- Leadership involvement in management review

- Process approach implementation

- Use of data for decision making

- Evidence of continual improvement

Strong application of QMS principles leads to smoother audits and fewer nonconformities.

QMS Principles PDF

Frequently Asked Questions

What are the 7 principles of QMS?

The 7 principles of QMS are Customer Focus, Leadership, Engagement of People, Process Approach, Improvement, Evidence-Based Decision Making, and Relationship Management.

Are ISO 9001 and IATF 16949 QMS principles the same?

Yes, both standards use the same quality management principles. IATF 16949 applies them more strictly to the automotive industry.

Why are QMS principles important?

QMS principles help organizations achieve consistent quality, improve customer satisfaction, and drive continual improvement.

Change in QMS Principles in IATF 16949 :

Below are the changes made to QMS principles in this revised standard (ISO 9001:2015/IATF 16949:2016)

- Customer focus is replaced by Stakeholder focus.

- The management representative (MR) is removed. Responsibility is given to top management and the process owners.

- The involvement of people changes their engagement.

- Process approach and system approach combined to the Process approach.

- Continual improvement changes to improvement.

- Factual approach to decision-making changes to evidence-based decision-making.

- Mutually beneficial supplier relationship converts to relationship management.

Benefits of 7 QMS Principles:

Benefits of Customer Focus :

- Improvement in Customer values.

- Improve customer satisfaction.

- Improved customer loyalty.

- Business will increase.

- Understand customer needs and expectations and continuously work to fulfill them.

Benefits of leadership :

- Increased effectiveness and efficiency in meeting the organization’s quality objectives.

- Better coordination of the organization’s processes.

- Improved communication within the organization.

- Communicate the organization’s Vision, Mission, Policies, and Objectives throughout the organization.

Benefits of engaging the people:

Improved understanding of the organization’s quality objectives by people in the organization and increased motivation to achieve them.

Benefits of the process approach:

- Enhanced ability to focus effort on key processes

- Optimized performance through efficient use of resources and effective process management.

- Establish authority, responsibility and accountability for managing processes.

Benefits of improvement:

Enhanced focus on root-cause investigation and determination, followed by preventive and corrective actions

Continuous improvements shall be objective at all levels of the organization.

Benefits of evidence-based decision-making:

- Improved decision-making processes.

- Improved assessment of process performance and ability to achieve objectives.

- Increased ability to review, challenge and change opinions and decisions.

- Determine, measure and monitor key performance indicators to demonstrate the organization’s performance.

Benefits of relationship management:

- Sustained success is more likely to be achieved when the organization manages relationships with all of its interested parties to optimize their impact on its performance.

- A common understanding of goals and values among interested parties.

- Determine relevant interested parties (such as suppliers, partners, customers, investors, employees and society as a whole) and their relationship with the organization.

Conclusion

The 7 QMS principles are the backbone of effective quality management systems used in ISO 9001 and IATF 16949. Understanding the 7 principles of QMS enables organizations to move beyond certification and build a strong, process-driven quality culture.

For more detailed information about the new Quality Management Principles.

It’s an extremely beautiful site!

Although I enjoy your website, you should proofread a few of your pieces. Many of them have serious spelling errors, which makes it difficult for me to convey the truth. Nevertheless, I will definitely return.

Hi my friend! I want to say that this post is awesome, nice written and include approximately all important infos. I would like to see more posts like this.