In any manufacturing plant, automotive industry, service operation, or technical system, monitoring the reliability and maintainability of equipment is essential. Two of the most widely used metrics for this purpose are Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR). These metrics help answer two fundamental questions:

- How long does a machine run before it fails? (Reliability)

- How long does it take to bring the machine back to working condition after failure? (Maintainability)

Understanding MTTR and MTBF helps maintenance teams reduce breakdowns, improve equipment availability, support preventive maintenance, reduce the cost of poor maintenance, and increase overall productivity (Overall Equipment Effectiveness). This article explains their meaning, formulas, examples, interpretation, common mistakes, and guides on how to implement them effectively.

What is MTBF?

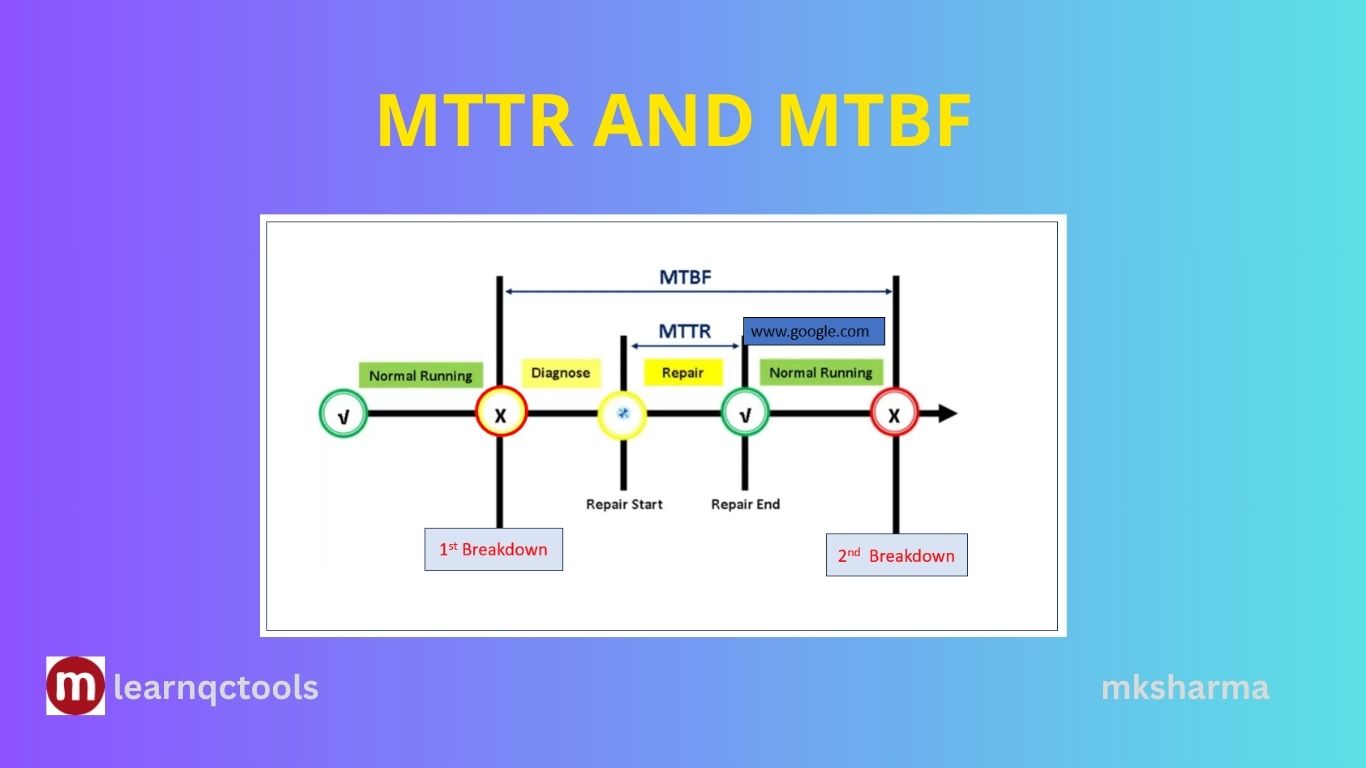

MTBF stands for Mean Time Between Failures. It represents the average time a repairable machine or system operates before experiencing a failure. MTBF is used for machines, tools, automation lines, and any equipment that undergoes repair and continues operating.

Formula:

MTBF = Total Operational Time ÷ Number of Failures

Operational time means actual running or uptime hours, excluding downtime due to breakdowns.

Example:

Available time in a month: 396 hours

Downtime due to breakdowns: 6 hours

Actual running time = 396 – 6 = 390 hours

Number of failures = 3

MTBF = 390 ÷ 3 = 130 hours

If your machine has an MTBF of 130 hours, it means on average the machine runs 130 hours before a breakdown.

Why MTBF matters:

• A higher MTBF indicates a more reliable machine.

• Helps in planning preventive maintenance schedules.

• Reduces unplanned downtime and improves production flow.

• Useful for long-term maintenance planning and spare parts forecasting.

• Used in TPM, Lean Manufacturing, and IATF 16949 audits as a reliability metric.

What is MTTR?

MTTR stands for Mean Time To Repair. It is the average time taken to repair a failed machine and bring it back to operating condition. MTTR includes fault detection, diagnosis, repair work, testing, and machine restart.

Formula:

MTTR = Total Repair Time ÷ Number of Repairs

Example:

If the total repair time in a month is 4.5 hours and breakdowns are 3, then

MTTR = 4.5 ÷ 3 = 1.5 hours

Why MTTR matters:

• A lower MTTR means faster repairs and reduced downtime.

• Indicates the effectiveness of maintenance teams.

• Measures response time, spare parts availability, and technician skill.

• Helps identify bottlenecks in repair processes.

• Improves machine availability and OEE.

MTBF vs MTTR

MTBF shows reliability (how often the machine fails).

MTTR shows maintainability (how fast you fix it).

High MTBF + Low MTTR = Excellent equipment performance

Low MTBF + High MTTR = Worst-case reliability and maintainability

MTBF and MTTR together give a true picture of equipment health. A machine with high MTBF but very high MTTR may still cause major losses due to long repair times. Similarly, a machine with low MTBF but low MTTR may still disrupt flow due to frequent stops.

Common Mistakes in MTTR/MTBF Calculation

Many organisations calculate these metrics incorrectly. The most common errors are:

• Not recording all failures (minor stoppages ignored)

• Inaccurate logging of start time and end time of breakdowns

• Including preventive maintenance downtime in MTBF

• Not including diagnosis time, waiting time, and test run in MTTR

• Comparing MTBF across machines that operate under different loads

• Using MTBF for non-repairable items (should use MTTF instead)

• Calculating using calendar hours instead of running hours

• Missing shift changes, lunch breaks, testing delays etc.

To avoid wrong results, standardise your definition in the maintenance SOP and train operators/technicians to record time accurately.

Where MTBF and MTTR are used

Although most plants use MTTR and MTBF for machines, these metrics are widely used in:

• Automotive component manufacturing

• Press shops, CNC, VMC, injection moulding

• Process industries like chemical and pharma

• IT systems, servers, cloud reliability

• Electrical panels, automation systems, robotics

• Service contracts and breakdown response SLAs

• Reliability engineering and warranty analysis

How to Implement MTBF and MTTR in your plant

Step 1: Set up accurate data recording

Record every breakdown clearly with:

• Breakdown start time

• Repair start time

• Repair completion time

• Cause of failure

• Parts used

• Technician assignment

• Category of failure (electrical, mechanical, hydraulic)

Step 2: Define what counts as a failure

Create clarity in your SOP:

• What is considered a breakdown?

• Are stoppages under 5 minutes included?

• Is tool change a breakdown?

• Is waiting for the material to be counted?

• What part of the repair cycle counts as MTTR?

Step 3: Calculate MTTR and MTBF monthly

Monitor trends, not just individual values.

If MTBF is reducing, → machine reliability is declining.

If MTTR is increasing, → slow maintenance response or resource issues.

Step 4: Use the metrics for decision-making

If MTBF is low:

• Perform root cause analysis

• Implement preventive maintenance

• Upgrade or replace wearing components

• Train operators

• Improve lubrication and cleaning schedules

If MTTR is high:

• Improve technician skill and staffing

• Improve spare parts availability

• Prepare standard repair procedures

• Reduce diagnosis time

• Improve access to tools

• Reduce machine complexity

Step 5: Combine MTBF/MTTR with other reliability metrics

For complete maintenance monitoring, also use:

• MTTF (Mean Time To Failure) – for non-repairable parts

• Failure rate

• Planned vs unplanned downtime

• Breakdown frequency

• OEE (Availability component)

Practical Calculation Template

| Date | Machine | Failure Start | Repair Start | Repair End | Downtime | Cause |

|---|---|---|---|---|---|---|

| 02-Dec-2025 | Press P1 | 14:10 | 14:30 | 15:45 | 1.25h | Hydraulic leak |

| 05-Dec-2025 | CNC 3 | 11:20 | 11:20 | 11:50 | 0.5h | Tool break |

Monthly Summary

Total Operating Time = Available Time – Total Downtime

MTBF = Operating Time ÷ Total Failures

MTTR = Total Downtime ÷ Total Failures

You can add this table directly to your post to help users understand practical implementation.

Interpretation of MTBF and MTTR in Real Life

A plant manager or maintenance engineer should not see these numbers only as formulas. They indicate deeper issues.

If MTBF is continuously dropping:

• Machines need frequent repairs

• Reliability is declining

• Preventive maintenance is ineffective

• Spares may be of low quality

• Operator handling may be incorrect

• The machine may be nearing the end of its life

If MTTR is increasing:

• Shortage of skilled technicians

• Delay in diagnosis

• Spare parts not stocked

• Complicated machine design

• Improper repair SOPs

• Long waiting time for tools or approvals

Tracking MTBF and MTTR month by month gives early signals so problems can be fixed before affecting production output.

Why MTTR and MTBF are important for IATF 16949, ISO 9001, and TPM

These metrics are critical in quality management systems because they directly impact:

• Process capability

• OEE

• Customer delivery performance

• Cost of poor quality

• Process reliability

• Continuous improvement

• Maintenance planning

• Layered process audits (LPA)

• Risk-based thinking (ISO 9001:2015), Audit and Compliance (IATF 16949 Clauses)

IATF auditors often ask:

• How do you measure machine reliability?

• How do you reduce downtime?

• What actions are taken when MTBF decreases?

• How do you ensure maintenance effectiveness?

By using MTBF and MTTR data, you can confidently answer these questions.

Example: Calculating MTTR for a Machine

Let’s calculate the Mean Time To Repair (MTTR) for a machine over one month.

- Number of Breakdowns: 3

- Repair Times:

- Breakdown 1: 1 hour

- Breakdown 2: 1.5 hours

- Breakdown 3: 2 hours

- Total Repair Time = 1 + 1.5 + 2 = 4.5 hours

- MTTR = Total Repair Time ÷ Number of Breakdowns

MTTR = 4.5 ÷ 4 = 1.5 hours

So, the average time to repair the machine after a failure is 1.5 hours.

How to calculate Mean Time between Failure (MTBF) and Mean Time to Repair (MTTR) in Excel:

Download the MTTR and MTBF Calculation Excel Sheet.

Update the breakdown details date-wise.

Update the monthly available time as per working hours and working days in a month.

After updating these data, MTBF and MTTR will be calculated automatically.

How to improve the Mean Time to Repair?

For improving MTTR, we have to reduce breakdown time and breakdown numbers. So, for reducing MTTR, there are some steps to follow:

- Standardise, review and update the Maintenance procedure. Follow the Work Instructions and Checklists as defined in the procedure.

- When a breakdown occurs, do an effective breakdown analysis to find out the actual root cause. Take corrective action, implement effectiveness monitoring and do horizontal deployment. There must not be any repetitive breakdown.

- Maintain the critical spare parts as defined in the critical spare parts list and review this list at least monthly.

- Predictive maintenance and preventive maintenance are effective in reducing the MTTR. So, follow the maintenance plan practically.

Summary

MTBF tells how long a machine runs before failing.

MTTR tells how quickly you repair it.

Both are essential to improve uptime, reduce breakdowns, and maintain smooth production flow.

Higher MTBF = more reliable equipment

Lower MTTR = faster repairs

Together = improved machine availability and efficiency

With proper data logging, accurate calculations, trend monitoring, and structured improvement actions, these two metrics become powerful tools for any industry.

Related Articles

• What Is OEE? – https://learnqctools.in/oee

• 7 QC Tools With Shopfloor Examples – https://learnqctools.in/7-qc-tools

• Complete Guide to FMEA – https://learnqctools.in/fmea

• CAPA Process Explained – https://learnqctools.in/corrective-action-and-preventive-action

• Control Chart Examples – https://learnqctools.in/control-chart

• IATF 16949 Clauses Explained – https://learnqctools.in/iatf-clause

- How to implement the Machine maintenance procedure in a manufacturing industry?

- How to implement the Tool maintenance procedure in a manufacturing industry?

Regards for this post, I am a big fan of this site would like to go on updated.