Root Cause Analysis (RCA) is a systematic problem-solving method used to identify the underlying cause of a defect, failure, incident, or nonconformity so that it does not recur. Instead of treating symptoms, RCA focuses on eliminating the fundamental cause of the problem.

RCA is widely used in quality management, manufacturing, engineering, healthcare, IT, safety investigations, and service industries. It is a key requirement in ISO 9001 and IATF 16949 for corrective action and continuous improvement.

By identifying and removing the true cause, organizations can prevent repeated failures, reduce costs, improve reliability, and enhance customer satisfaction.

What is a Root Cause?

A root cause is the most basic reason a problem occurs. If the root cause is removed, the problem will not happen again.

Example:

Problem: Product rejected due to dimension out of tolerance

Immediate cause: Tool wear

Root cause: Preventive maintenance not followed

Fixing the tool temporarily treats the symptom, but implementing a maintenance system removes the root cause.

Why Root Cause Analysis is Important

Organizations that only address symptoms often experience recurring problems. RCA ensures long-term solutions rather than temporary fixes.

Key benefits include:

• Prevents recurrence of defects and failures

• Reduces cost of poor quality (COPQ)

• Improves process reliability and productivity

• Enhances safety and compliance

• Supports continuous improvement initiatives

• Improves customer satisfaction

Types of Root Causes

Most problems originate from one or more of the following categories:

Physical Causes

Failures due to equipment, materials, or environmental conditions.

Examples: Machine breakdown, material defects, power fluctuations

Human Causes

Errors caused by actions or decisions of people.

Examples: Improper operation, lack of training, negligence

Organizational Causes

Weak systems, policies, or processes.

Examples: Poor procedures, inadequate supervision, lack of preventive maintenance

Understanding these categories helps teams investigate problems systematically.

Root Cause Analysis Methods and Tools

Several structured techniques are used to identify root causes. Organizations often use multiple tools together for better accuracy.

1. 5 Why Analysis

The 5 Why technique involves repeatedly asking “Why?” until the underlying cause is identified.

Example:

Problem: Machine stopped

Why? Fuse blown

Why? Overload occurred

Why? Bearing seized

Why? Lubrication insufficient

Why? Maintenance schedule not followed

Root cause: Lack of preventive maintenance system

2. Fishbone (Cause-and-Effect) Diagram

Also called the Ishikawa Diagram, this tool visually categorizes possible causes of a problem under headings such as Man, Machine, Method, Material, Measurement, and Environment.

It is one of the 7 Basic Quality Tools and widely used in brainstorming sessions.

3. Pareto Analysis

Pareto analysis prioritizes causes based on frequency or impact using the 80/20 rule. It helps focus on the few causes responsible for most problems.

4. Fault Tree Analysis (FTA)

A top-down approach that uses logical diagrams to analyze failure pathways, commonly used in safety and reliability engineering.

5. Failure Mode and Effects Analysis (FMEA)

A proactive method that identifies potential failures and their effects before they occur.

6. 8D Problem Solving Method (8D)

A team-based approach widely used in the automotive industry for customer complaints and major nonconformities.

Step-by-Step Root Cause Analysis Process

A structured process improves accuracy and effectiveness.

Step 1: Define the Problem Clearly

Specify what happened, where, when, and how often.

Step 2: Collect Data

Gather facts, measurements, records, and observations. Avoid assumptions.

Step 3: Identify Possible Causes

Brainstorm potential causes using tools like Fishbone Diagram or process mapping.

Step 4: Determine the Root Cause

Analyze evidence to confirm which cause actually triggered the problem.

Step 5: Implement Corrective Actions

Develop solutions that eliminate the root cause, not just the symptom.

Step 6: Verify Effectiveness

Monitor results to ensure the problem does not recur.

Root Cause Analysis Example (Manufacturing)

A company experiences frequent customer complaints about paint peeling on metal parts.

Investigation findings:

Immediate cause: Poor paint adhesion

Possible causes: Surface contamination, improper curing, incorrect paint mix

Using 5 Why analysis:

Why peeling occurs? Poor adhesion

Why adhesion poor? Surface not clean

Why surface not clean? Degreasing ineffective

Why degreasing ineffective? Chemical concentration low

Why concentration low? No monitoring system

Root cause: Lack of control over degreasing chemical concentration

Corrective action: Implement concentration monitoring and standard operating procedure.

Root Cause Analysis in ISO 9001 and IATF 16949

RCA is essential for quality management systems.

It is used in:

• Corrective and preventive actions (CAPA)

• Nonconformity investigations

• Internal and external audit findings

• Customer complaints

• Supplier issues

• Safety incidents

• Continuous improvement projects

Certification bodies expect organizations to demonstrate systematic RCA rather than superficial fixes.

Advantages of Root Cause Analysis

• Eliminates recurring problems

• Improves product and process quality

• Reduces downtime and waste

• Supports data-driven decisions

• Enhances reliability and safety

• Builds a culture of continuous improvement

Limitations of Root Cause Analysis

• Can be time-consuming

• Requires skilled team involvement

• Depends on accurate data

• Multiple root causes may exist

• Incorrect analysis can lead to ineffective solutions

Root Cause vs Symptom

A symptom is a visible sign of a problem, while a root cause is the underlying reason.

Treating symptoms provides short-term relief, but eliminating root causes delivers permanent solutions.

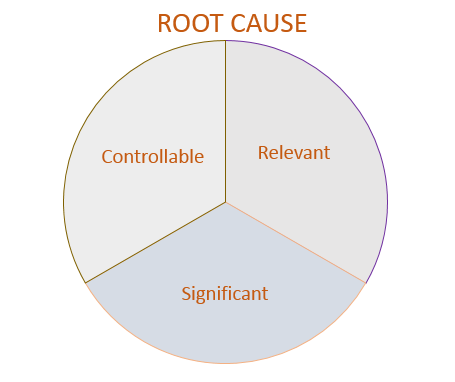

3 Requirements of the Root Cause:

- The root cause must be relevant to the problem. If it is not relevant to the problem then it is not the root cause.

- It must be controllable. If the root cause is not controllable then it is not the root cause.

- It must be significant.

What are the 5 Whys of Root Cause Analysis?

Five whys were invented by Sakichi Toyoda in 1920. There are 2 categories for why why analysis.

Occurrence:

The first category is related to the process that made the defective part. Why did it occur? We focus on the real root cause of occurrence here. So that when we take action on the real root cause of the problem. It will not be repeated.

Detection:

The second one must address the detection system that could not detect the defective part.

- Why did the outflow happen?

- Why was it not detected in our factory?

- Why did the part go to the customer? So in this category, we focus on the second step detection.

5 Whys are not always necessary to reach the root cause of the problem. It may take less or more than 5 whys to get to the root cause. It could be 4 whys or 6 whys. It will depend upon the complexity of the problem.

Stop asking why if your common sense says you have reached the controllable step of a process, relevant document, policy or a concerned person ( operator or supervisor)

As this tool is purely observation-driven, keep asking the next why until you feel the root cause has become evident.

Useful Tools for determining Root cause analysis:

- 5 Whys

- Pareto analysis

- Brain Storming

- Flow Chart

- Cause and Effect Diagram

- Tree Diagram

Practical Examples of Root Cause Analysis :

Case Study 1 :

Problem: Flat Tyre of a Car

| Why 1 | Why 2 | Why 3 | Why 4 | Why 5 | Root Cause |

|---|---|---|---|---|---|

| Nails on the garage floor | Nails cartoon split open | Cartoon got wet | Rain through a hole in the garage roof | Roof tiles are missing | The roof is not a part of the daily checklist |

Case Study 2:

Problem: The CNC Machine stopped

| Why 1 | Why 2 | Why 3 | Why 4 | Why 5 | Root Cause |

|---|---|---|---|---|---|

| The overload circuit tripped | The pump was seized | Metal chips damaged the shaft | Chips entered the lubrication system | No filter on the inlet pipe | The sump design is not OK |

Case Study 3:

Problem: Rod Length under size on Band saw cutting

| Why 1 | Why 2 | Why 3 | Why 4 | Why 5 | Root Cause |

|---|---|---|---|---|---|

| Rod movement less | Limit switch plunger not moving | Plunger jammed | Chips got into the plunger | No cover on the plunger and limit switch | Machine design not OK |

Case Study 4:

Problem: Blowhole in Aluminum casting

| Why 1 | Why 2 | Why 3 | Why 4 | Why 5 | Root Cause |

|---|---|---|---|---|---|

| Casting filling is not OK | Molten metal does not reach the effective area | Casting ends before filling area | Casting design as per model | Design not adequate | The Gate opening design is not adequate |

Case Study 5:

Problem: Punching out in Sheet metal parts

| Why 1 | Why 2 | Why 3 | Why 4 | Why 5 | Root Cause |

|---|---|---|---|---|---|

| Part shifted | Locator gauge shifted | Locator loose | Bolt loose | Hardened bolt not used | No checkpoint in the design for the use of hardened bolt |

Case Study 6:

Why why for the occurrence of a Blow Hole in the Pressure die casting process due to air entraption:

| Why-1 | Why is air entrapped during metal flow? |

| Ans | Sleeve filling ratio more ( 55%) |

| Why-2 | Sleeve filling ratio more ( 55%)? |

| Ans | Effective sleeve area less |

| Why-3 | Effective sleeve area less? |

| Ans | Plunger dia less (50mm) |

| Why-4 | Plunger dia less (50mm) ? |

| Ans | As per standard practice, the die was designed according to the model and past history data are not considered |

Root Cause: As per standard practice, the die was designed according to the model and past history data are not considered

Case Study 7:

Why why analysis for the occurrence of a crack in sheet metal parts:

| Why-1 | Why crack on parts after bending? |

| Ans | Heavy burr on the edge of the blank |

| Why-2 | Heavy burr on the edge of the blank? |

| Ans | The cutting edge of the die worn out |

| Why-3 | The cutting edge of the die worn out? |

| Ans | Cutting edge is worn out before the defined resharpening frequency |

| Why-4 | Cutting edge worn out before the defined resharpening frequency? |

| Ans | Tool resharpening frequency not reviewed as per past history |

Root cause: Tool resharpening frequency should be revised as per past history.

Frequently Asked Questions (FAQs)

What is root cause analysis used for?

It is used to identify the underlying cause of problems to prevent recurrence.

What is the difference between root cause and immediate cause?

Immediate cause triggers the problem directly, while root cause is the fundamental reason behind it.

Which tools are used in root cause analysis?

Common tools include 5 Why Analysis, Fishbone Diagram, Pareto Chart, FMEA, Fault Tree Analysis, and 8D.

Is RCA required in ISO 9001?

Yes, ISO 9001 requires organizations to investigate nonconformities and take actions to prevent recurrence, which involves RCA.

How many root causes can a problem have?

A problem may have one or multiple root causes depending on complexity.

Conclusion

Root Cause Analysis is a powerful method for solving problems permanently rather than temporarily. By identifying and eliminating the true cause, organizations can prevent recurrence, reduce costs, improve quality, and enhance operational performance.

Whether applied to manufacturing defects, safety incidents, customer complaints, or process failures, RCA is essential for effective problem solving and continuous improvement.

For organizations implementing ISO 9001 or IATF 16949, strong RCA practices are critical for compliance and long-term success.

👉Need expert support in solving recurring quality issues? QC Tools Solutions provides professional QMS consultancy, RCA training, and implementation support tailored for manufacturing organizations.