Overall Equipment Effectiveness, commonly known as OEE, is one of the most important performance indicators used in Lean Manufacturing to measure how efficiently manufacturing equipment is utilised. OEE helps organisations identify losses, improve productivity, reduce downtime, and increase output without additional investment. In automotive, engineering, and process industries, OEE is widely used as a core metric under TPM, Kaizen, and IATF 16949 continual improvement systems.

Many companies calculate OEE but fail to use it effectively due to incorrect definitions, poor data collection, or a misunderstanding of its purpose. This article explains how to calculate OEE in Lean manufacturing, using clear definitions, formulas, practical shopfloor examples, common mistakes, benchmarks, and implementation best practices.

- What is OEE in Lean Manufacturing?

- Why OEE is Important in Lean Manufacturing

- OEE Formula Explained

- Key Terms Used in OEE Calculation

- Step-by-Step OEE Calculation in Lean Manufacturing

- Step 1: Calculate Availability

- Step 2: Calculate Performance

- Step 3: Calculate Quality

- Step 4: Calculate OEE

- OEE Calculation Summary Table

- What is a Good OEE Value?

- OEE and the Six Big Losses

- Common Mistakes in OEE Calculation

- How to Implement OEE on the Shopfloor

- OEE in TPM and Continuous Improvement

- OEE and IATF 16949 Requirements

- Difference Between OEE, Efficiency, and Productivity

- Frequently Asked Questions on OEE

- Overall Equipment Effectiveness (OEE) calculation :

- OEE Calculation Example:

- OEE Calculation Excel Sheet

- Conclusion:

What is OEE in Lean Manufacturing?

OEE stands for Overall Equipment Effectiveness. It measures how effectively a manufacturing process operates compared to its full potential during planned production time. OEE provides a single percentage value that reflects the true productivity of a machine or process.

OEE is not just a number. It is a diagnostic tool that highlights where losses occur and supports data-driven decision-making in Lean Manufacturing.

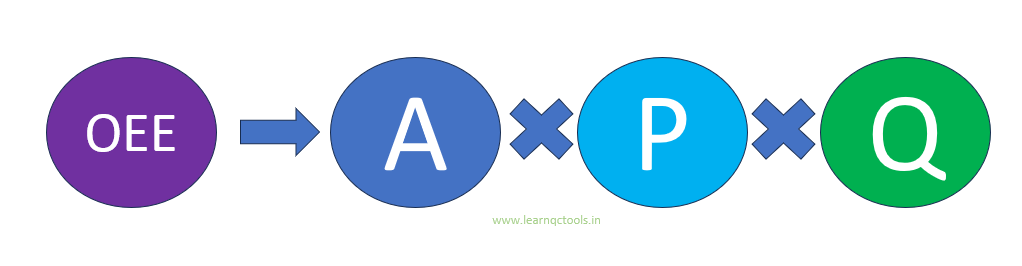

OEE consists of three components:

Availability

Performance

Quality

OEE answers one key question:

How much of the planned production time is actually used to produce good parts at the right speed?

Why OEE is Important in Lean Manufacturing

Lean Manufacturing focuses on eliminating waste and maximising value. OEE directly supports this objective by identifying losses related to equipment and processes.

Benefits of using OEE include:

- Identification of hidden losses

- Improved equipment utilisation

- Reduced downtime and breakdowns

- Better production planning

- Higher product quality

- Stronger TPM and Kaizen implementation

For automotive suppliers and IATF 16949 certified organisations, OEE also provides objective evidence of process performance monitoring and continual improvement.

OEE Formula Explained

The standard OEE formula is:

OEE = Availability × Performance × Quality

Each factor represents a different category of loss. When multiplied together, they give the overall effectiveness of the equipment during planned production time.

Key Terms Used in OEE Calculation

Correct OEE calculation starts with clear and consistent definitions. The following terms must be understood and agreed upon across production, maintenance, and quality teams.

Planned Production Time

This is the time during which production is scheduled to run. Planned breaks such as lunch breaks, tea breaks, and planned maintenance are excluded.

Run Time

Run Time is the actual time the machine is running. It is calculated by subtracting unplanned downtime from Planned Production Time.

Unplanned Downtime

Any event that stops production unexpectedly, such as breakdowns, tool failure, material shortage, power failure, or operator absence.

Ideal Cycle Time

The minimum time required to produce one part under ideal conditions. This should be based on machine capability, not average performance.

Total Count

The total number of parts produced, including defective parts.

Good Count

The number of defect-free parts that meet quality requirements.

Step-by-Step OEE Calculation in Lean Manufacturing

To make OEE easy to understand and implement, it should be calculated step by step.

Step 1: Calculate Availability

Availability measures losses due to stoppages.

Availability Formula

Availability = Run Time ÷ Planned Production Time

Availability losses are caused by equipment failures, setup delays, tool change delays, and unplanned stoppages.

Example

Planned Production Time = 480 minutes

Unplanned Downtime = 60 minutes

Run Time = 480 − 60 = 420 minutes

Availability = 420 ÷ 480 = 0.875 or 87.5%

Step 2: Calculate Performance

Performance measures losses due to slow running and minor stops.

Performance Formula

Performance = (Ideal Cycle Time × Total Count) ÷ Run Time

Performance losses occur when machines run below their design speed or experience frequent small stoppages.

Example

Ideal Cycle Time = 1 minute per part

Total Parts Produced = 380

Run Time = 420 minutes

Performance = (1 × 380) ÷ 420 = 0.905 or 90.5%

Performance should never exceed 100%. If it does, the Ideal Cycle Time definition is incorrect.

Step 3: Calculate Quality

Quality measures losses due to defects and rework.

Quality Formula

Quality = Good Count ÷ Total Count

Quality losses occur due to process variation, tool wear, setup issues, or material defects.

Example

Total Parts Produced = 380

Defective Parts = 20

Good Count = 360

Quality = 360 ÷ 380 = 0.947 or 94.7%

Step 4: Calculate OEE

OEE Formula

OEE = Availability × Performance × Quality

OEE = 0.875 × 0.905 × 0.947

OEE = 0.75 or 75%

This means that only 75% of the planned production time is truly productive.

OEE Calculation Summary Table

Availability = 87.5%

Performance = 90.5%

Quality = 94.7%

OEE = 75%

This breakdown helps teams understand exactly where losses are occurring.

What is a Good OEE Value?

OEE benchmarks vary by industry, but general Lean Manufacturing standards are:

Below 60% – Poor performance

60% to 70% – Average

70% to 85% – Good

Above 85% – World-class

World-class OEE of 85% is challenging and usually achieved only with strong TPM systems, stable processes, and disciplined maintenance.

OEE and the Six Big Losses

OEE is directly linked to the Six Big Losses in Lean Manufacturing.

Availability Losses

Breakdowns

Setup and adjustment

Performance Losses

Minor stoppages

Speed loss

Quality Losses

Startup defects

Production defects

By mapping OEE losses to the Six Big Losses, organisations can systematically eliminate waste.

Common Mistakes in OEE Calculation

Many companies fail to get correct OEE results due to the following mistakes:

Including planned breaks in Planned Production Time

Ignoring micro stoppages

Using average cycle time instead of ideal cycle time

Allowing Performance to exceed 100%

Calculating OEE without verifying data accuracy

Using OEE only for reporting, not improvement

Correct definitions and consistent data collection are critical for meaningful OEE analysis.

How to Implement OEE on the Shopfloor

To successfully implement OEE in Lean Manufacturing, follow these best practices.

Start with one critical machine

Define terms clearly and document them

Collect data manually or digitally at the shift level

Review OEE daily with operators and supervisors

Focus on improving one loss at a time

Use root cause analysis tools such as Pareto, Why-Why, and Fishbone

Integrate OEE review into daily management meetings

OEE should be visible on the shopfloor through boards or dashboards.

OEE in TPM and Continuous Improvement

OEE is a core metric in Total Productive Maintenance. It supports TPM pillars such as Autonomous Maintenance, Planned Maintenance, and Focused Improvement.

OEE trends help maintenance teams move from reactive maintenance to preventive and predictive maintenance.

In Kaizen activities, OEE data provides factual evidence of improvement results.

OEE and IATF 16949 Requirements

In IATF 16949, organisations are required to monitor and measure manufacturing process performance. OEE supports compliance with clauses related to:

- Process performance monitoring

- Continual improvement

- Risk-based thinking

- Maintenance effectiveness

Auditors often expect to see OEE data analysis, improvement actions, and result tracking.

Difference Between OEE, Efficiency, and Productivity

OEE is often confused with efficiency or productivity, but they are not the same.

Efficiency typically compares actual output to planned output.

Productivity focuses on output per resource.

OEE measures true equipment effectiveness by combining availability, speed, and quality.

OEE provides deeper insight than traditional efficiency metrics.

Frequently Asked Questions on OEE

What is the full form of OEE?

OEE stands for Overall Equipment Effectiveness.

How often should OEE be calculated?

OEE should be calculated shift-wise or daily for effective control.

Can OEE be more than 100%?

No, OEE cannot exceed 100%. If it does, the input data or ideal cycle time is incorrect.

Is OEE applicable to manual processes?

OEE is primarily designed for equipment-based processes, but similar concepts can be adapted for manual operations.

Is OEE mandatory in IATF 16949?

OEE is not mandatory, but it is a widely accepted best practice for process performance monitoring.

Overall Equipment Effectiveness (OEE) calculation :

OEE is the product of Availability, Performance and Quality. OEE is calculated as a percentage.

OEE % = Availability % x Performance % x Quality %

OEE Calculation Example:

Calculate OEE by considering a shift of 8 hrs, Machine breakdown of 30 minutes, Total production of 3800 parts and rejection of 20 parts and the target as per cycle time is 4000 parts.

Availability = ((Total available time – Breakdown time) / Total available time) x100

Availability = ((480 – 30) / 480)*100 = (450 / 480)x100 = 93.75%

Performance = Production Quantity / ( Net available time x Cycle Time ) x 100

Performance = (3800 / 4000) x100= 95%

Quality = (Total OK Products / Total Production) x 100

Quality = (3780 / 3800) x100 = 99.47%

OEE = Availability x Performance x Quality

OEE = 93.75% x 95% x 99.47% = 88.59%

OEE Calculation Excel Sheet

Download the OEE Excel Sheet

Update the data date-wise as per the format.

Conclusion:

OEE (Overall Equipment Effectiveness) is a lean manufacturing tool and universal best practice to monitor, evaluate and improve the effectiveness of a production process. This could be an assembly line, machine cell, packaging line etc. But it can also be considered a strong financial indicator. When expressed in monetary terms, the OEE metric can be used to illustrate the potential economic impact of optimising production and justify investments to increase efficiency in your plant.

OEE is a powerful Lean Manufacturing tool that reveals how effectively equipment is being used. When calculated correctly and analysed consistently, OEE helps organisations identify losses, improve equipment reliability, and enhance overall productivity.

Instead of focusing only on achieving a high OEE number, organisations should focus on reducing Availability, Performance, and Quality losses step by step. When used as an improvement tool, OEE becomes a strong foundation for TPM, Lean Manufacturing, and operational excellence.

You may like other lean tools: Jidoka in lean manufacturing,

What is Poka Yoke (Error Proofing)?

Thanks for fantastic info I was looking for this information for my mission.