What is the APQP Responsibility Matrix?

The APQP Responsibility Matrix is an essential tool used in the automotive and manufacturing industries. It clearly defines the roles and responsibilities of departments involved in new product development and launch. APQP (Advanced Product Quality Planning) ensures quality, customer satisfaction, and reliability throughout the product lifecycle.

By using a responsibility matrix, organizations avoid confusion, delays, and duplication of work during APQP implementation.

Why is the Responsibility Matrix Important?

- Ensures role clarity across departments

- Improves accountability and communication

- Minimizes delays and errors in product launch

- Supports compliance with IATF 16949 and customer requirements

Key Elements of the Matrix

- Responsible (R): Team executing the activity

- Accountable (A): Department answerable for the success of the activity

- Consulted (C): Teams providing expertise or inputs

- Informed (I): Stakeholders updated on progress

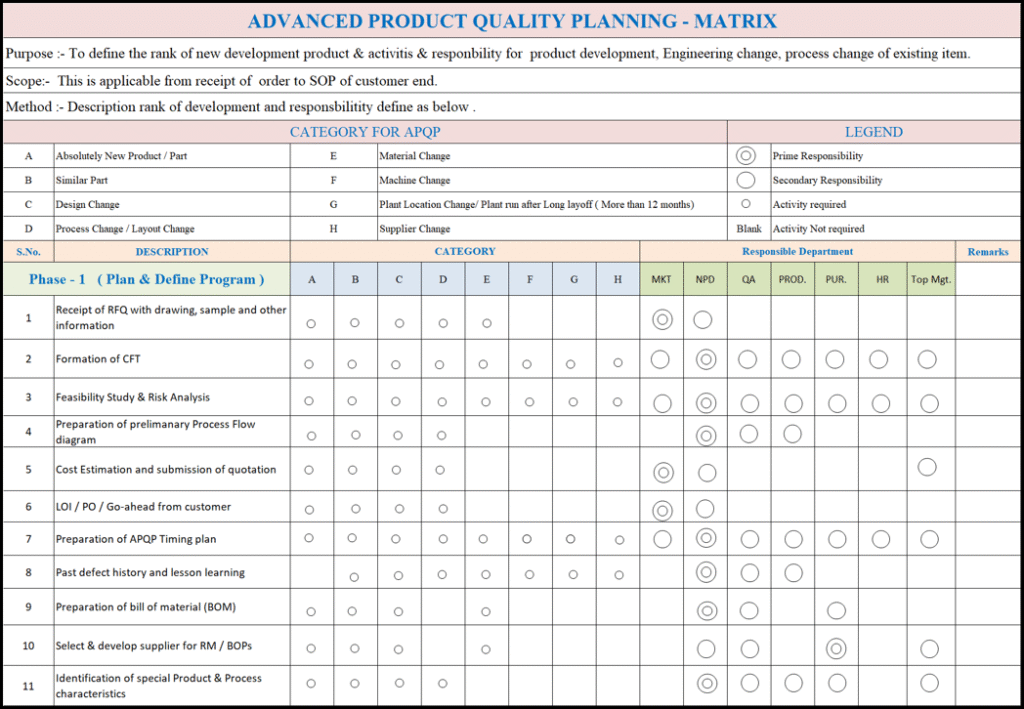

Development Categories in APQP

| Development Category | Code |

|---|---|

| New Part | A |

| Similar Part | B |

| Design Change (ECN) | C |

| Process Change (PCN) | D |

| Material Change | E |

| Machine Change | F |

| Plant Location Change | G |

| Supplier Change | H |

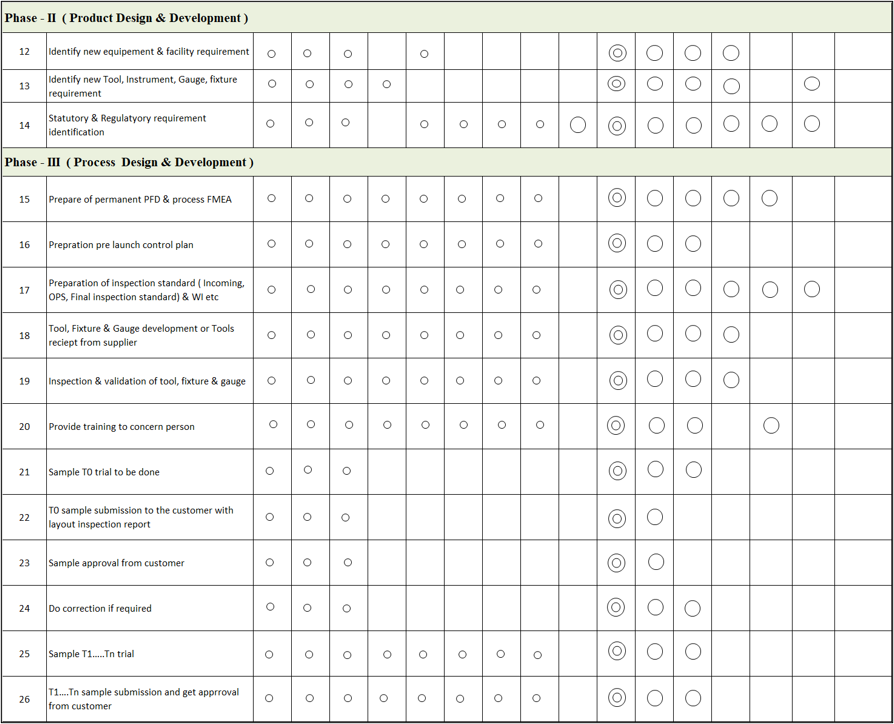

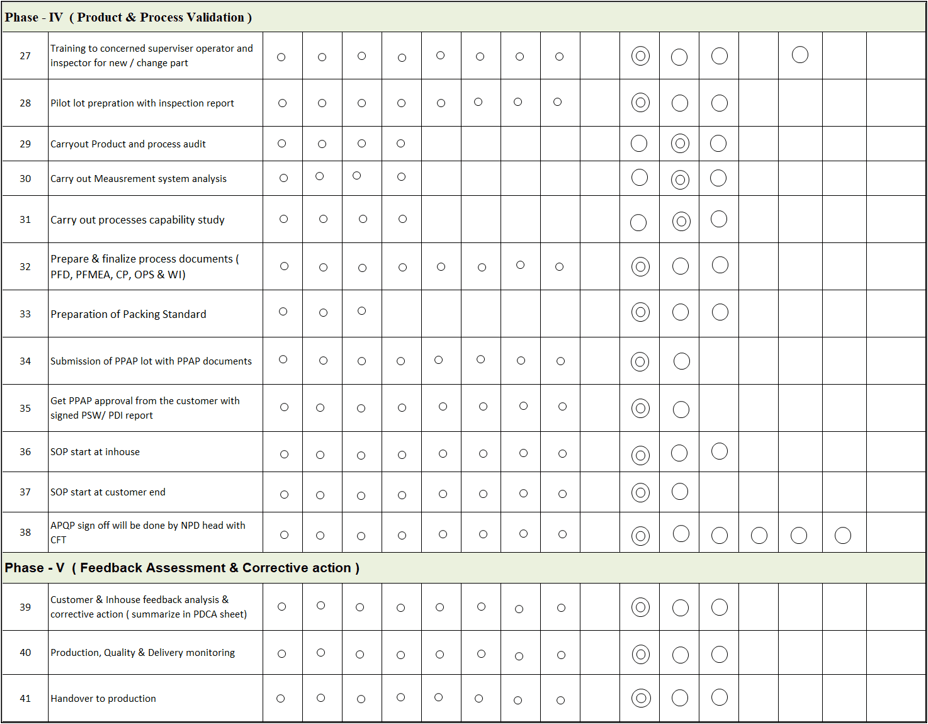

Example of APQP Matrix

Each APQP Matrix—from RFQ receipt to SOP at customer end—assigns primary and secondary responsibilities:

- Marketing → Prime responsibility for RFQ receipt

- NPD / Engineering → Secondary responsibility for early design support

- Production, QA, Purchase, Supplier Quality → Assigned roles across validation and launch phases

- Categories for APQP are defined by a category code (A to H).

- The matrix categorizes activities according to their application.

- A small circle indicates the applicable activity.

- For each activity, the responsible department is marked with:

- Double circle: Primary responsibility

- Single circle: Secondary responsibility

Example – Activity No. 1: “Receipt of RFQ with drawing”

- Applicable in categories A, B, C, D & E

- Prime responsibility: Marketing department

- Secondary responsibility: NPD department

Similarly, all other activities and responsibilities can be easily understood from the APQP matrix.

APQP Responsibility Chart:

Benefits of Using APQP Responsibility Matrix

- Aligns all functions during product development

- Reduces rework and conflicts between teams

- Provides a standard reference during audits

- Helps in supplier–customer communication

Download APQP Matrix Excel Template

👉 Download APQP Matrix Excel to customize for your organization.

FAQs

Q1. What is an APQP Responsibility Matrix?

It is a structured chart that defines departmental responsibilities in all APQP phases.

Q2. Why should companies use it?

It ensures accountability, faster decision-making, and error-free product launches.

Q3. Who prepares the APQP Responsibility Matrix?

Usually prepared by the Quality or NPD team, with inputs from all functions.

Q4. How many categories are there in the APQP Matrix?

The APQP Matrix uses eight categories (A to H), covering new parts, design changes, process changes, supplier changes, and more.

Q5. How does the APQP Matrix support IATF 16949 compliance?

By clearly defining responsibilities and documenting activities, the APQP Matrix ensures that all IATF 16949 requirements are addressed during product development.

Conclusion

The APQP Responsibility Matrix streamlines roles, ensures accountability, and reduces errors in product development. It aligns teams across all APQP phases and supports compliance with standards like IATF 16949. By applying it effectively, companies can achieve smoother launches and higher customer satisfaction.

You may like to read about:

Sir format have protection

Plz password share to unprotected

By which we can follow this

It can be downloaded easily and no password.

Very well presented. Every quote was awesome and thanks for sharing the content. Keep sharing and keep motivating others.

It can be downloaded easily and no password.

Fantastic blog!