Quality Objectives (KPI):

Quality objectives are the SMART goals for enhancing customer satisfaction and are relevant to the company’s quality policy. Quality objectives are defined when establishing the quality management system or during management review. It is also called a KPI (Key Performance Indicator). Each department should define its KPI.

- Quality Objectives (KPI):

- List of the Quality Objectives :

- Customer Complaints:

- Customer Rejection PPM:

- In-house complaints:

- In-house rejection PPM:

- Cost of Poor Quality (COPQ):

- Internal Audit:

- Product and Process Audit:

- External Audit (Customer audit):

- Machine Breakdown Hours:

- Preventive Maintenance as per plan:

- Tool Breakdown Hours:

- Inventory Turnover Ratio (ITR):

- Overall Equipment Effectiveness (OEE):

- Number of Kaizens :

- Turnover (Sales) :

- Supplier performance :

- Supplier Audit :

List of the Quality Objectives :

Customer Complaints:

Customer complaints are the complaints registered by the customer. Customer complaints are monitored month-wise against the target and a trend chart is maintained to show the data. The target for customer complaints must be zero. It is the marketing department KPI as per IATF & also related to the quality & production department.

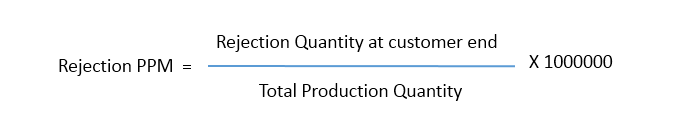

Customer Rejection PPM:

Customer rejection PPM is monitored month-wise against the target and a trend chart is maintained to show the data. it is also called customer PPM. Where PPM means Parts per million. The target for customer rejection PPM should be zero.

Rejection PPM = (Reject qty at customer end / Total dispatch qty) x 1000000

In-house complaints:

In-house complaints are the complaints that are captured inside the company. We must do red bin analysis to capture in-house complaints. In-house complaints are monitored month-wise against the target and a trend chart is maintained.

We should take action with a defect analysis report (DAR) on the top in-house complaints as per the Pareto chart. We should collect rejection data of processes/departments like the press, machining, welding & assembly, etc. We should take action on the top defect of each department separately.

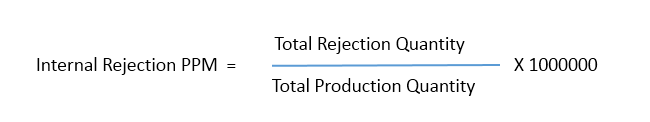

In-house rejection PPM:

In-house rejection PPM is monitored month-wise against the target and a trend chart is maintained. The target for in-house PPM should be at least 20% less than the previous year’s target. If in-house rejection PPM is more than the target, then corrective action must be taken.

In house Rejection PPM= (Total rejection / Total production) x 1000000

Cost of Poor Quality (COPQ):

The cost incurred in producing & rectifying a defect is called the cost of poor quality. The cost of poor-quality data is maintained month-wise against the target and a trend chart is maintained. If it is more than the target, then we should take corrective action.

Internal Audit:

Internal audits are done as per plan ( recommend 6-month frequency) & with a departmental internal audit check sheet. All non-conformities ( NC ) should be closed within the period as defined in the Internal Audit procedure.

Learn about Internal Audit Procedure

Product and Process Audit:

Product and process audits are done as per plan with a Process audit check sheet and Control plan. All NCs should be closed within the period as defined in the internal audit procedure.

External Audit (Customer audit):

Customer audits and Certification body audits (BSI, TUV, DNV) are reviewed and all NCs should be closed timely as per the action plan to close all non-conformities.

Machine Breakdown Hours:

It is the total breakdown of hours incurred in all machines in a month. Month-wise data should be captured against the target. Calculate the mean time to repair (MTTR) and the mean time between failures (MTBF).

Read more about Machine Maintenance Procedure

Preventive Maintenance as per plan:

Preventive maintenance of machines & tools should be as per plan. In the preventive maintenance plan, all machines as per the master list of machines should be covered.

Tool Breakdown Hours:

It is the total breakdown of hours incurred in all tools in a month. Month-wise data should be captured against the target. Follow the Tool Maintenance procedure.

Inventory Turnover Ratio (ITR):

It is the ratio of the yearly sales of a company and the average inventory.

ITR = Sales / Average Inventory (Year)

If we need to calculate monthly, then

ITR = (Sale of month x 12) / Monthly average inventory

For more details about the Inventory Turnover Ratio.

Overall Equipment Effectiveness (OEE):

Calculate the OEE of the plant/shop. OEE is the product of the Availability, Performance & Quality ratio. It should be as per the target decided. OEE should be as high as possible. From OEE, we will get the plant efficiency & effectiveness.

Number of Kaizens :

Kaizen should be implemented each month by each department as per the target. Kaizen can be categorized as an improvement in Productivity, Quality, Cost reduction, Delivery, Safety & Morale ( PQCDSM). It is part of the continual improvement process in the company.

Turnover (Sales) :

Sales turnover is the main key performance indicator of top management & marketing departments. Sales should be as per the target decided and customer demand.

Supplier performance :

Calculate the supplier rating each month. It should be as per the target. Supplier rating should be calculated based on some criteria like Rejection, quality problem, customer line disruption, delivery failure, premium freight and others.

For more details about Supplier control management.

Supplier Audit :

Supplier audit should be done as per the plan with a supplier audit check sheet. All observations should be closed by the supplier.

Simply want to say your article is as surprising. The clarity in your post is simply nice and i could assume you’re an expert on this subject. Well with your permission allow me to grab your feed to keep up to date with forthcoming post. Thanks a million and please continue the gratifying work.