What is IATF 16949?

IATF 16949:2016 is the international quality management standard specifically designed for the automotive industry. It is based on ISO 9001:2015, but includes additional automotive-specific requirements that ensure product quality, safety, and customer satisfaction.

The standard is developed by the International Automotive Task Force (IATF) and applies to all automotive suppliers and manufacturers worldwide.

The standard focuses on preventing defects, reducing risks, meeting customer requirements, and ensuring continual improvement. It also includes important tools like APQP (Advanced Product Quality Planning) and PPAP (Production Part Approval Process), which help companies maintain high quality and reliability.

IATF 16949 is the global automotive Quality Management System (QMS) standard developed by the International Automotive Task Force (IATF).

It follows the structure of ISO 9001:2015 and includes 10 main clauses, with additional automotive-specific requirements.

This guide provides:

- Complete clause list

- Sub-clauses explained simply

- Comparison with ISO 9001

- Downloadable PDF clause summary

This is the most simplified and practical explanation for beginners, QMS professionals, and auditors.

IATF 16949 Clause List (10 Main Clauses)

IATF 16949 follows the High-Level Structure (HLS) of ISO 9001 and includes the same 10 clauses:

| Clause No. | Clause Title | Simple Explanation |

|---|---|---|

| 1 | Scope | Defines what the standard covers. |

| 2 | Normative References | Lists documents required for interpretation. |

| 3 | Terms & Definitions | Definitions used in the standard. |

| 4 | Context of the Organisation | Understanding internal/external issues, processes, and expectations. |

| 5 | Leadership | Responsibilities of top management. |

| 6 | Planning | Risks, opportunities, and QMS objectives. |

| 7 | Support | Resources, competence, awareness, communication, and documentation. |

| 8 | Operation | All manufacturing, design, supplier, & production controls. |

| 9 | Performance Evaluation | Monitoring, audits, KPIs, customer satisfaction. |

| 10 | Improvement | Corrective actions, problem-solving, and continual improvement. |

These clauses form the backbone of the automotive QMS.

IATF 16949 Detailed Clauses & Sub-Clauses Explained

Below is a simplified explanation of important sub-clauses that users often search for:

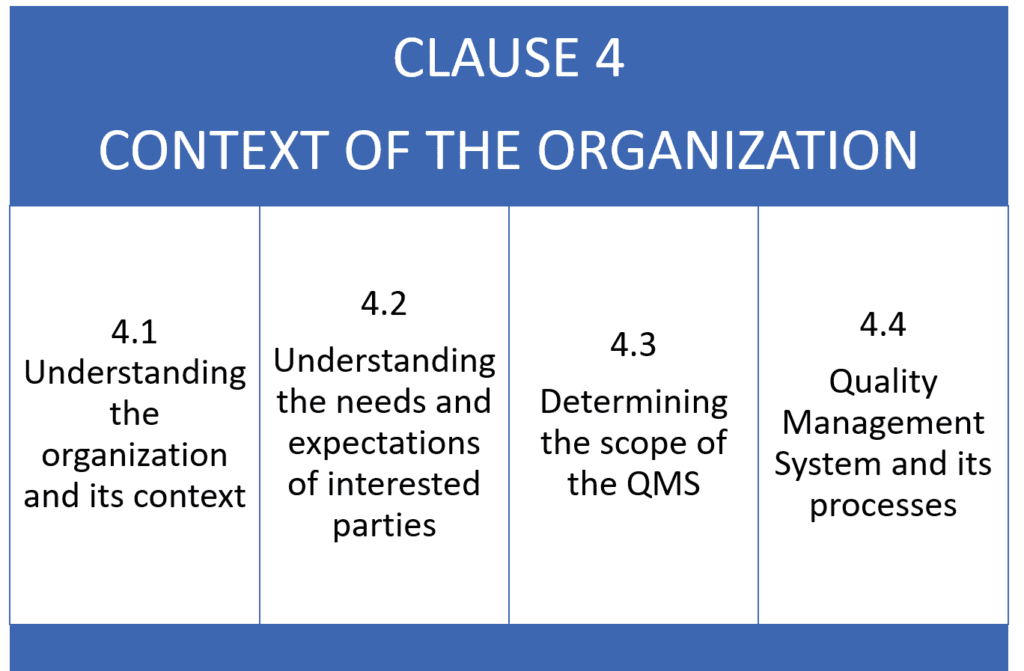

Clause 4: Context of the Organisation

- Identify internal & external issues

- Understand customer and interested-party expectations

- Define process sequence & interactions

- Maintain a process approach

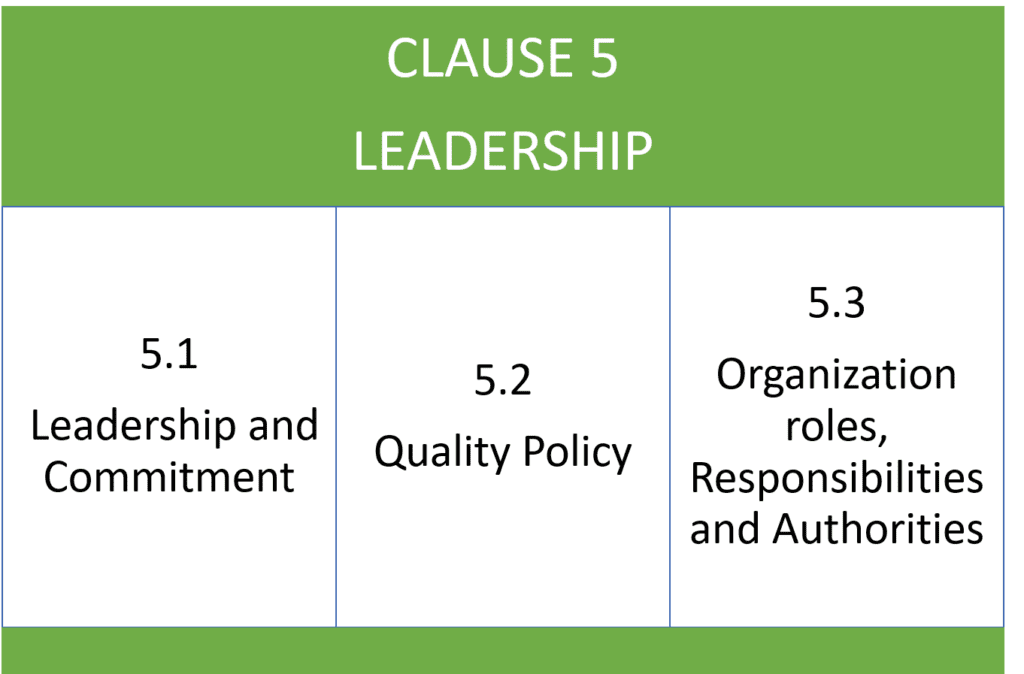

Clause 5: Leadership

- Top management must demonstrate commitment

- Define QMS policy & objectives

- Assign roles and responsibilities

- Promote customer focus

Clause 6: Planning

Includes:

- Risk-based thinking

- Risk analysis (FMEA, PFMEA, DFMEA where applicable)

- QMS objectives and plans

- Change management planning

Clause 7: Support

Covers everything needed to operate QMS:

- Competence & training

- Awareness

- Internal and external communication

- Documented information

- Calibration and measurement instruments

Clause 8: Operation (Most Important in Automotive)

Clause 8 contains many automotive-specific requirements:

8.3 Design & Development

- Design planning

- Design review

- Design verification & validation

- Design changes

- Design records

8.4 Control of External Providers (Supplier Management)

- Supplier selection & monitoring

- Supplier risk classification

- Supplier development

- Outsourced process control

8.5 Production & Service Provision

Key IATF-specific sub-clauses:

| Clause | Requirement |

|---|---|

| 8.5.1.1 | Control Plan |

| 8.5.1.2 | Standardized Work |

| 8.5.1.3 | Verification at Start-up |

| 8.5.1.5 | Total Productive Maintenance (TPM) |

| 8.5.1.6 | Management of Production Tools |

| 8.5.2.1 | Identification & Traceability |

| 8.5.6.1 | Control of Reworked Product |

8.6 & 8.7

- Final inspection

- Non-conforming product control

- Customer communication on NCs

Clause 9: Performance Evaluation

- Internal audits

- Customer satisfaction monitoring

- KPIs and process performance

- Management review

Clause 10: Improvement

- Corrective action

- Root cause analysis using appropriate methods (5 Why, Ishikawa, 8D)

- Continual improvement

- Lessons learned

IATF 16949 vs ISO 9001 Clause Structure

Both standards have the same 10 clauses.

Difference: IATF adds automotive-specific requirements such as:

- Control plans

- APQP elements

- PFMEA/DFMEA

- Supplier monitoring requirements

- Warranty management

- Error-proofing

- Traceability

This makes IATF more detailed and customer-specific.

Why Understanding Clauses is Important?

- Helps during internal and external audits

- Reduces customer complaints

- Supports robust QMS implementation

- Ensures process consistency

- Improves employee awareness

What are the Clauses of IATF 16949?

The IATF 16949 standard is divided into 10 main clauses, following the same structure as ISO 9001:2015. Clauses 1 to 3 are introductory, while clauses 4 to 10 define the Quality Management System (QMS) requirements that every organisation must implement.

In this post, we will go through all the IATF 16949 clauses and requirements in simple terms so you can clearly understand what each one means and why it is important for certification and success in the automotive industry.

This standard applies to all manufacturing facilities supplying to the automotive segment. Also there are regular revisions (Sanctioned Interpretations, SIs) in the IATF 16949 standard, which can be checked at the IATF global oversight.

IATF Clauses List:

There are 10 clauses in this IATF standard. Clauses 1, 2 and 3 provide the background of the standard. Clauses 4 to 10 provide the automotive QMS standard. Below is the list of IATF clauses in the PDCA cycle.

What are the 10 Clauses of IATF 16949?

The 10 clauses of IATF 16949 are:

- Scope

- Normative References

- Terms and Definitions

- Context of the Organization

- Leadership

- Planning

- Support

- Operation

- Performance Evaluation

- Improvement

These clauses define requirements for establishing an effective Automotive Quality Management System (QMS), ensuring defect prevention, risk management, and continual improvement.

IATF 16949 Clauses and Requirements:

IATF Clause 1: SCOPE

- 1.1 Scope – Automotive supplemental to ISO 9001:2015

IATF Clause 2: Normative References

- 2.1 Normative and Informative References

IATF Clause 3: Terms and Definitions

IATF Clause 4: Context of the Organisation

- 4.1 Understanding the organization and its context.

- 4.2 Understanding the needs and expectations of interested parties.

- 4.3 Determining the scope of the quality management system.

- 4.3.1 Determining the scope of the quality management system-supplemental.

- 4.3.2 Customer-specific requirements (CSR)

- 4.4 Quality management system & its processes.

- 4.4.1 (ISO 9001:2015): The organization shall establish, implement, maintain and continually improve a quality management system.

- 4.4.1.1 Conformance of Products & Processes.

- 4.4.1.2 Product safety

- 4.4.2 (ISO 9001:2015): The organization shall maintain and retain documented information to support the operation of its processes.

IATF Clause 5: Leadership

- 5.1 Leadership and Commitment

- 5.1.1 General

- 5.1.1.1 Corporate responsibility

- 5.1.1.2 Process effectiveness & efficiency.

- 5.1.1.3 Process owners

- 5.1.2 Customer focus

- 5.2 Quality Policy

- 5.2.1 Establishing the Quality Policy.

- 5.2.2 Communicating the Quality Policy.

- 5.3 Organisational roles, responsibilities and authorities.

- 5.3.1 Organizational roles, responsibilities and authorities-supplemental.

- 5.3.2 Responsibilities and authorities for product requirements and corrective actions.

IATF Clause 6: Planning

- 6.1 Actions to address risks and opportunities

- 6.1.1 (ISO 9001:2015): The organization shall consider the issues (4.1) and requirements (4.2) and determine the risks and opportunities.

- 6.1.2 (ISO 9001:2015): The organization shall plan actions to address these risks and opportunities.

- 6.1.2.1 Risk analysis

- 6.1.2.2 Preventive actions

- 6.1.2.3 Contingency plans

- 6.2 Quality objectives and planning to achieve them

- 6.2.1 (ISO 9001:2015): The organization shall establish quality objectives at relevant functions, levels, and processes needed for the quality management system.

- 6.2.2 (ISO 9001:2015): The organization shall determine 4W1H when planning to achieve its objectives.

- 6.2.2.1 Quality objectives and planning to achieve them – supplemental.

- 6.3 Planning of changes

IATF Clause 7: Support

- 7.1 Resources

- 7.1.1 General (ISO 9001:2015): The organization shall determine and provide the resources needed for the establishment, implementation, maintenance and continual improvement of the QMS.

- 7.1.2 People (ISO 9001:2015): The organization shall determine and provide the personnel required for the effective implementation of the QMS.

- 7.1.3 Infrastructure (ISO 9001:2015): The organization shall determine, provide and maintain the infrastructure for the operation and to achieve conformity of product and service.

- 7.1.3.1 Plant, facility, & equipment planning

- 7.1.4 Environment for the operation of processes (ISO 9001:2015):

- 7.1.4.1 Environment for the operation of processes-supplemental

- 7.1.5 Monitoring & measuring resources

- 7.1.5.1 General (ISO 9001:2015): The organization shall determine and provide the resources needed to ensure valid and reliable results when monitoring.

- 7.1.5.1.1 Measurement system analysis (MSA)

- 7.1.5.2 Measurement traceability (ISO 9001:2015)

- 7.1.5.2.1 Calibration/verification records

- 7.1.5.3 Laboratory requirements

- 7.1.5.3.1 Internal laboratory

- 7.1.5.3.2 External laboratory

- 7.1.6 Organizational knowledge (ISO 9001:2015)

- 7.2 Competence (ISO 9001:2015)

- 7.2.1 Competence – supplemental

- 7.2.2 Competence – on-the-job training (OJT)

- 7.2.3 Internal Auditor Competency

- 7.2.4 Second-party auditor competency

- 7.3 Awareness (ISO 9001:2015): The organization shall ensure the persons doing work are aware of the quality policy and quality objectives.

- 7.3.1 Awareness – supplemental

- 7.3.2 Employee motivation & empowerment

- 7.4 Communication (ISO 9001:2015): The organization shall determine the internal and external communication relevant to the QMS.

- 7.5 Documented information

- 7.5.1 General (ISO 9001:2015): The organisation’s QMS shall include the documented information required by this international standard.

- 7.5.1.1 Quality Management System Documentation

- 7.5.2 Creating & updating (ISO 9001:2015)

- 7.5.3 Control of Documented Information

- 7.5.3.1 (ISO 9001:2015): The documented information shall be controlled and adequately protected.

- 7.5.3.2 (ISO 9001:2015): The organisation shall address the following activities as applicable distribution, storage, control of changes, retention and disposition.

- 7.5.3.2.1 Record retention

- 7.5.3.2.2 Engineering specifications

Mandatory procedures as per IATF 16949

IATF Clause 8: Operation

- 8.1 Operational planning and control (ISO 9001:2015): The organization shall plan, implement and control the processes needed to meet the requirements for the provision of the products and services.

- 8.1.1 Operational planning and control – supplemental

- 8.1.2 Confidentiality

- 8.2 Requirements for products & services

- 8.2.1 Customer communication (ISO 9001:2015)

- 8.2.1.1 Customer communication – Supplemental

- 8.2.2 Determine the requirements for products & services (ISO 9001:2015)

- 8.2.2.1 Determine the requirements for products & services – Supplemental

- 8.2.3 Review of the requirements for products & services

- 8.2.3.1(ISO 9001:2015): The organization shall ensure that it can meet the requirements for products and services to be offered to the customers.

- 8.2.3.1.1 Review of the requirements for products & services – Supplemental

- 8.2.3.1.2 Customer-designated special characteristics

- 8.2.3.1.3 Organization manufacturing feasibility

- 8.2.3.2 (ISO 9001:2015): The organization shall retain documented information on the result of the review.

- 8.2.4 Changes to Requirements for Products and Services

- 8.3 Design & development of products & services

- 8.3.1 General (ISO 9001:2015): The organization shall establish, implement and maintain a design and development process that is appropriate to ensure the subsequent provision of products and services.

- 8.3.1.1 Design & development of products & services – supplemental

- 8.3.2 Design & development planning (ISO 9001:2015)

- 8.3.2.1 Design & Development Planning – supplemental

- 8.3.2.2 Product Design Skills

- 8.3.2.3 Development of products with embedded software

- 8.3.3 Design & development Inputs (ISO 9001:2015)

- 8.3.3.1 Product Design Input

- 8.3.3.2 Manufacturing Process Design Input

- 8.3.3.3 Special Characteristics

- 8.3.4 Design & development Control (ISO 9001:2015)

- 8.3.4.1 Monitoring

- 8.3.4.2 Design & development validation

- 8.3.4.3 Prototype programme (see also ISO 9001:2015, clause section 8.4)

- 8.3.4.4 Product approval process

- 8.3.5 Design & development Outputs (ISO 9001:2015)

- 8.3.5.1 Design & development outputs – supplemental

- 8.3.5.2 Manufacturing Process Design Output

- 8.3.6 Design & development Changes (ISO 9001:2015)

- 8.3.6.1 Design & development changes – supplemental

- 8.4 Control of externally provided processes, products and services

- 8.4.1 General (ISO 9001:2015): The organization shall ensure that externally provided products and services conform to requirements.

- 8.4.1.1 General – supplemental

- 8.4.1.2 Supplier selection process

- 8.4.1.3 Customer-directed sources (also known as “Directed-Buy”)

- 8.4.2 Type & extent of control (ISO 9001:2015)

- 8.4.2.1 Type & extent of control-supplemental

- 8.4.2.2 Statutory and regulatory requirements

- 8.4.2.3 Supplier Quality Management System Development

- 8.4.2.3.1 Automotive product-related software or automotive products with embedded software

- 8.4.2.4 Supplier monitoring

- 8.4.2.4.1 Secondary-party audits

- 8.4.2.5 Supplier development

- 8.4.3 Information for external providers (ISO 9001:2015)

- 8.4.3.1 Information for external providers – supplemental

- 8.5 Production and service provision

- 8.5.1 Control of production and service provision (ISO 9001:2015)

- 8.5.1.1 Control Plan

- 8.5.1.2 Standardized work – operator instructions and visual standards

- 8.5.1.3 Verification of job set-ups

- 8.5.1.4 Verification after shutdown

- 8.5.1.5 Total productive maintenance (TPM)

- 8.5.1.6 Management of production tooling and manufacturing test, inspection and equipment

- 8.5.1.7 Production scheduling

- 8.5.2 Identification and traceability (ISO 9001:2015)

- 8.5.2.1 Identification and traceability – supplemental

- 8.5.3 Property belonging to customer or external providers (ISO 9001:2015)

- 8.5.4 Preservation (ISO 9001:2015)

- 8.5.5 Post-delivery activities (ISO 9001:2015)

- 8.5.5.1 Feedback of information from the service

- 8.5.5.2 Service agreement with customer

- 8.5.6 Control of changes (ISO 9001:2015)

- 8.5.6.1 Control of changes – supplemental

- 8.5.6.1.1 Temporary change of process controls

- 8.6 Release of products and services (ISO 9001:2015)

- 8.6.1 Release of products and services – supplemental

- 8.6.2 Layout inspection and functional testing

- 8.6.3 Appearance items

- 8.6.4 Verification and acceptance of conformity of externally provided products and services

- 8.6.5 Statutory and regulatory conformity

- 8.6.6 Acceptance criteria (refer to section 9.1.1.1 also)

- 8.7 Control of Nonconforming Outputs

- 8.7.1 (ISO 9001:2015): The organization shall ensure that outputs that do not conform to their requirements are identified and controlled to prevent their unintended use or delivery.

- 8.7.1.1 Customer authorization for concession

- 8.7.1.2 Control of nonconforming products – customer-specific process

- 8.7.1.3 Control of suspect product

- 8.7.1.4 Control of Reworked Product

- 8.7.1.5 Control of Repaired Product

- 8.7.1.6 Customer notification

- 8.7.1.7 Nonconforming Product Disposition

- 8.7.2 (ISO 9001:2015): The organization shall retain documented information that describes the non-conformity, action taken and any concession obtained.

IATF Clause 9: Performance Evaluation

- 9.1 Monitoring, measurement, analysis and evaluation

- 9.1.1 General (ISO 9001:2015): The organisation shall determine what needs to be monitored and measured and the method by which the monitoring and measurement shall be performed.

- 9.1.1.1 Monitoring & measurement of manufacturing processes

- 9.1.1.2 Identification of statistical tools

- 9.1.1.3 Application of statistical concepts (SPC)

- 9.1.2 Customer satisfaction (ISO 9001:2015)

- 9.1.2.1 Customer satisfaction- supplemental

- 9.2 Internal audit

- 9.2.1 (ISO 9001:2015): The organisation shall conduct an internal audit at planned intervals to provide information on whether the QMS conforms to the requirements of the international standard.

- 9.2.2 (ISO 9001:2015): The organisation shall plan, establish, implement and maintain an audit program including the frequency, method, responsibilities, planning requirements and reporting.

- 9.2.2.1 Internal audit program

- 9.2.2.2 Quality Management System Audit

- 9.2.2.3 Manufacturing Process Audit

- 9.3 Management review

- 9.3.1 General (ISO 9001:2015): The organisation shall review the QMS at the planned interval to ensure its continuing suitability, adequacy, effectiveness and alignment with the strategic direction of the organization.

- 9.3.1.1 Management review – supplemental

- 9.3.2 Management review inputs

- 9.3.2.1 Management review inputs – supplemental

- 9.3.3 Management review outputs (ISO 9001:2015)

- 9.3.3.1 Management review Outputs -supplemental

IATF Clause 10: Improvement

- 10.1 General (ISO 9001:2015): The organization shall determine and select opportunities for improvements and implement any necessary actions to meet customer requirements.

- 10.2 Nonconformity and corrective action

- 10.2.1 (ISO 9001:2015): When a non-conformity occurs, including any arising from the complaints, take action to control and correct it.

- 10.2.2 (ISO 9001:2015): The organisation shall retain documented information as evidence of the nature of the non-conformities and any subsequent action taken and the result of any action taken.

- 10.2.3 Problem-solving

- 10.2.4 Error-proofing

- 10.2.5 Warranty Management Systems

- 10.2.6 Customer complaints and field failure test analysis

- 10.3 Continual improvement (ISO 9001:2015): The organisation shall continually improve the suitability, adequacy and effectiveness of the QMS.

- 10.3.1 Continual improvement – supplemental

Summary IATF Clause 10: Improvement

Clause 10 of IATF 16949 focuses on continual improvement of the QMS. It requires organisations to:

- Address nonconformities and take corrective actions.

- Use data analysis to identify recurring issues.

- Implement root cause analysis for every customer complaint.

- Measure the effectiveness of corrective actions.

- Promote a culture of continual improvement at all levels.

This clause ensures that lessons learned from audits, customer feedback, and production issues lead to real process improvements.

10 Clauses of IATF 16949 Explained in Simple Words

- Scope: Where and how the standard applies.

- Normative References: Supporting ISO standards to follow.

- Terms and Definitions: Common terms like customer-specific requirements.

- Context of Organisation: Understanding the environment and stakeholders.

- Leadership: Top management roles and communication of the quality policy.

- Planning: Risk-based thinking, objectives, and change management.

- Support: People, infrastructure, environment, and documentation.

- Operation: Product realisation, supplier control, and validation.

- Performance Evaluation: Internal audits, KPIs, and customer feedback.

- Improvement: Continual improvement and corrective actions.

Download IATF 16949 Clauses PDF

Get the simplified printable version of IATF 16949 clause list + sub-clauses + one-line explanations.

This PDF includes:

- List of all 10 clauses and their subclauses

- Summary of key requirements

- Ideal for internal auditors, trainers, and quality professionals

Make sure to keep this checklist handy during your IATF 16949 internal audit or supplier evaluation.

Frequently Asked Questions (FAQ)

1. What are the clauses of IATF 16949?

There are 10 clauses in total, aligned with ISO 9001:2015, focusing on leadership, planning, support, operation, evaluation, and improvement.

2. How many clauses and subclauses are in IATF 16949?

There are 10 main clauses and around 80 subclauses covering detailed QMS requirements.

3. Can I download the IATF clauses in PDF format?

Yes, you can download the IATF 16949 Clauses PDF from the link above.

4. What is Clause 10 of IATF 16949?

Clause 10 deals with improvement — it includes corrective actions, continual improvement, and customer complaint handling.

5. Is IATF 16949 based on ISO 9001?

Yes, it builds upon ISO 9001:2015 and adds specific automotive quality requirements.

Conclusion

Understanding the IATF 16949 Clauses is essential for any organization working in the automotive supply chain. By implementing each clause effectively, companies can strengthen their quality management system, reduce customer complaints, and achieve continual improvement.

Download the free PDF summary to simplify your internal audit and training process.

You may like to know about:

ISO 45001 Clauses and Requirements (Occupational Health & Safety Management Systems)

EHS Requirement by Maruti Centre for Excellence (MAE)

This blog post is worth the read – trust us!

Thanks for best compliment

Good knowledge sharing

Thanks for your feedback