Measurement System Analysis (MSA) is one of the most important quality tools used in manufacturing and process industries to ensure that measurement data is accurate, reliable, and consistent. In quality management systems such as ISO 9001 and IATF 16949, decisions related to product acceptance, process capability, SPC, and improvement actions are all based on measurement results. If the measurement system itself is not reliable, even the best processes can be ineffective.

This detailed guide explains Measurement System Analysis in a practical and audit-oriented way, including MSA formulas, Gage R&R calculation, K1, K2, K3 table, types of MSA, examples, and MSA acceptance criteria as per AIAG guidelines.

- What is Measurement System Analysis (MSA)?

- Why Measurement System Analysis is Important

- Components of Measurement Variation

- Measurement System Analysis types

- Measurement System Analysis Formula

- Gage R&R k1 k2 k3 Table (AIAG Reference)

- Acceptance Criteria for Gage R&R

- Measurement System Analysis Example (Step-by-Step)

- Bias, Linearity, and Stability in MSA

- Common Problems Identified Through MSA

- Role of MSA in ISO 9001 and IATF 16949

- When is Measurement System Analysis required?

- Frequently Asked Questions on Measurement System Analysis

- Measurement System

- Measurement System example :

- How to implement a good measurement system?

- Number of distinct categories (NDC):

- Variable MSA Format:

- Conclusion

What is Measurement System Analysis (MSA)?

Measurement System Analysis is a structured method used to evaluate the accuracy, precision, and stability of a measurement system. A measurement system includes the measuring instrument, the operator, the method, the environment, and the part being measured.

In simple words, MSA answers one fundamental question:

“Can we trust the measurement data we are using for quality decisions?”

MSA is mandatory in the automotive and manufacturing industries because incorrect measurement data leads to wrong conclusions, unnecessary rejections, customer complaints, and audit non-conformities.

Why Measurement System Analysis is Important

Measurement variation directly affects product quality and process control

- Poor measurement systems make it difficult to distinguish between good and bad parts

- Helps identify measurement errors in instruments, methods, and operators

- Reduces inspection and measurement variation

- Improves confidence in Statistical Process Control (SPC) charts and process capability data

- Supports PPAP submissions with reliable measurement results

- Helps meet customer-specific and certification requirements

- Frequently checked during IATF 16949 audits, especially Gage R&R studies

Components of Measurement Variation

Total measurement variation is made up of two major components:

Repeatability (Equipment Variation – EV)

Reproducibility (Appraiser Variation – AV)

Together, these form Gage Repeatability and Reproducibility, commonly known as Gage R&R.

Part Variation (PV) is also evaluated to understand how much variation comes from the product itself compared to the measurement system.

Measurement System Analysis types

Measurement System Analysis is classified into two main categories depending on the nature of the data.

Variable Measurement System Analysis

Variable MSA is used when the measurement result is numerical, such as length, diameter, weight, thickness, or torque. Gage R&R is the most commonly used variable MSA method.

Attribute Measurement System Analysis

Attribute MSA is used when results are qualitative, such as OK/Not OK, Pass/Fail, Visual Inspection, or Go/No-Go decisions. Attribute Agreement Analysis is used to evaluate inspector consistency and accuracy.

In addition to these, MSA also includes Bias, Linearity, and Stability studies to evaluate long-term measurement performance.

Measurement System Analysis Formula

Below are the most important MSA and Gage R&R formulas used in practice.

Equipment Variation Formula (EV)

Equipment Variation represents repeatability, meaning variation when the same operator measures the same part multiple times using the same instrument.

EV = (Average Range × K1)

Where K1 is a constant based on the number of trials.

Appraiser Variation Formula (AV)

Appraiser Variation represents reproducibility, meaning variation between different operators measuring the same part.

AV = √[(X̄diff × K2)² − (EV² / (n × r))]

Where

X̄diff = Difference between operator averages

K2 = Constant based on the number of operators

n = Number of parts

r = Number of trials

Gage R&R Formula (GRR)

Gage R&R is calculated using:

GRR = √(EV² + AV²)

Part Variation Formula (PV)

PV = (Rp × K3)

Where Rp is the range of part averages and K3 is a constant based on sample size.

%GRR Formula

%GRR = (GRR / Total Variation) × 100

Total Variation = √(GRR² + PV²)

Measurement results used in the Control Plan must be supported by a valid MSA.

Gage R&R k1 k2 k3 Table (AIAG Reference)

The constants K1, K2, and K3 are used in Gage R&R calculations as per the AIAG MSA Manual.

For common studies:

- K1 depends on the number of trials

- K2 depends on the number of operators (Appraisers)

- K3 depends on the number of parts

Including this table in your MSA study is important because auditors often ask for justification of constants used in calculations.

Acceptance Criteria for Gage R&R

As per AIAG guidelines, Gage R&R results are interpreted as follows:

%GRR ≤ 10%

The measurement system is acceptable.

%GRR between 10% and 30%

A measurement system may be acceptable depending on the application, cost, customer requirements, and risk.

%GRR > 30%

The measurement system is not acceptable and must be improved.

These criteria are frequently checked during IATF 16949 audits and customer assessments.

Measurement System Analysis Example (Step-by-Step)

Consider a study with:

- 10 parts

- 2 operators

- 3 trials per part

Each operator measures all parts three times. The data is recorded and ranges are calculated for each part and operator.

Step 1: Calculate the average range for repeatability

Step 2: Calculate EV using K1

Step 3: Calculate operator averages and differences

Step 4: Calculate AV using K2

Step 5: Calculate GRR

Step 6: Calculate PV using K3

Step 7: Calculate %GRR and evaluate acceptability

This structured approach ensures transparency and audit readiness.

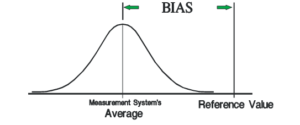

Bias, Linearity, and Stability in MSA

Bias

Bias is the difference between the observed measurement value and the reference or master value. Bias studies verify whether the measurement system consistently over- or under-measures.

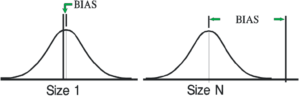

Linearity

Linearity evaluates whether bias remains consistent across the measurement range. It is especially important for instruments used over wide tolerance ranges.

Stability

Stability checks whether measurement results remain consistent over time. Stability studies are often reviewed during system audits.

Common Problems Identified Through MSA

Measurement System Analysis often reveals issues such as worn instruments, poor calibration practices, inadequate operator training, inconsistent measurement methods, environmental influences, and improper part fixturing.

| Issue Identified in MSA | Corrective Action |

|---|---|

| Worn or damaged measuring instruments | Replace or repair the instrument |

| Poor or irregular calibration practices | Implement a proper calibration schedule and traceability |

| Lack of operator training | Provide structured measurement and MSA training |

| Inconsistent measurement methods | Standardize measurement procedures and work instructions |

| Environmental influence (temperature, vibration, humidity) | Control the measurement environment or relocate the measurement activity |

| Improper or unstable part fixturing | Design and use proper fixtures or gauges |

| High inspection variation | Improve measurement technique or introduce automation |

Corrective actions may include instrument replacement, operator training, improved measurement procedures, better fixtures, or automation.

Role of MSA in ISO 9001 and IATF 16949

In ISO 9001, MSA supports clause requirements related to monitoring and measurement. In IATF 16949, MSA is mandatory for special characteristics, SPC implementation, and PPAP approvals. Also MSA is required for all types of measurements like variable, attribute and visual.

Auditors typically ask for:

- Latest Gage R&R studies

- Evidence of acceptance criteria

- Corrective actions for failed studies

- Linkage with control plans and SPC charts

When is Measurement System Analysis required?

MSA should be conducted during new product development, before PPAP submission, after instrument repair or replacement, when operators change, and when measurement results show unusual variation.

- During new product development, to validate measurement systems early

- Before PPAP submission to ensure reliable measurement data before SPC

- After instrument repair, modification, or replacement

- When there is a change in operators or measurement personnel

- When measurement results show unusual or unexpected variation

- During periodic reviews (Yearly Plan) to ensure long-term measurement system reliability

Frequently Asked Questions on Measurement System Analysis

What is MSA full form?

MSA stands for Measurement System Analysis.

What is the purpose of Measurement System Analysis?

The purpose of MSA is to evaluate whether a measurement system is reliable and suitable for its intended use.

What is an acceptable Gage R&R value?

A Gage R&R value of 10% or less is considered acceptable as per AIAG guidelines.

What is the difference between EV and AV?

EV represents equipment repeatability, while AV represents variation between different operators.

Is MSA mandatory in IATF 16949?

Yes, Measurement System Analysis is mandatory in IATF 16949, especially for special characteristics and SPC processes. MSA requirements are verified against relevant IATF 16949 clauses during audits.

How often should MSA be conducted?

MSA should be conducted initially and reviewed periodically or whenever there is a change in measurement conditions

Measurement System

A measurement System is the collection of instruments, standards, operations, methods, fixtures, software, inspectors, environment & assumptions used to quantify a unit of measure or fix assessment to the feature characteristics being measured. It is the complete process used to obtain a measurement during measurement system analysis. It is one of the 5 core tools.

Measurement System example :

To measure the diameter of a pipe, we need a system that includes:

- Item / Part for checking

- The inspector who will check (Appraiser)

- Method to use the instruments

- Environment

- Instruments

- Standard/Drawing

As a result of the activity, we decided based on a diameter value.

How to implement a good measurement system?

1. Identify all inspection, measuring & test equipment.

2. Ascertain bias, linearity & stability.

3. Conduct a variation study.

4. Provide the validity of previous results when the measuring instrument is out of calibration.

5. Ensure handling, preservation, cleaning, maintenance & storage of all instruments.

6. Use all criteria of measurement system analysis.

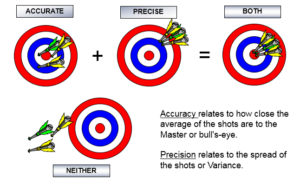

Accuracy & Precision:

Accuracy:

Accuracy is how close is the measurement value is to the reference value / actual value.

Precision:

Precision is the closeness of repeated readings to each other.

Accuracy and precision are not calculated as part of MSA.

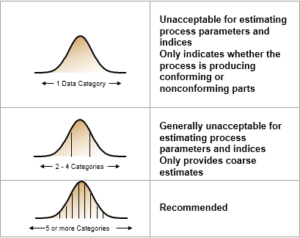

Number of distinct categories (NDC):

The number of distinct categories tells you how many separate groups of parts the system can distinguish.

NDC = (Part Variation/Gage R&R) x 1.41

It is recommended that the NDC should be equal to or more than 5

Variable MSA Format:

MSA Variable study format with Graph:

Conclusion

Measurement System Analysis is a foundational quality tool that ensures confidence in measurement data used for decision-making. By understanding MSA formulas, Gage R&R calculations, K1, K2, and K3 constants, acceptance criteria, and practical examples, organizations can strengthen their quality systems and avoid costly errors.

A robust MSA not only supports ISO 9001 and IATF 16949 compliance but also improves process capability, customer satisfaction, and continuous improvement initiatives. Investing time in proper Measurement System Analysis is essential for any organization committed to data-driven quality excellence.

Precisely and Accurately MSA has been present in nutshell 👌👍

I CAN’T UNDERSTAND OF K1,K2,K3 MEANING PLEASE EXPLAIN

Thanks for your feedback.

The terms K1, K2, and K3 are constants used to calculate measurement variation components. They depend on the number of trials (repetitions) and the number of appraisers/operators in your MSA study.

The constants K1, K2 and K3 are used in Gage R&R calculations as per the AIAG MSA Manual.

For common studies:K1 depends on the number of trials, K2 depends on the number of operators (Appraisers), K3 depends on the number of parts.

Can you please give me the password to unprotect sheet. I need to add some descriptions there for my colleague, but I cannot.

Please write a email regarding your requirement.