In modern manufacturing — especially in the automotive industry — shipping a defective or incorrect product can result in severe consequences such as customer complaints, line stoppage penalties, product recalls, and loss of reputation. To prevent such risks, organizations implement a critical quality control step called a Dock Audit.

A Dock Audit is the final inspection performed at the dispatch or shipping area before products leave the facility. It ensures that only conforming, correctly identified, and properly documented products are delivered to the customer.

This comprehensive guide explains the dock audit meaning, purpose, procedure, checklist, format, and its role in quality management systems such as IATF 16949.

What Is a Dock Audit?

A Dock Audit is a final verification activity conducted at the loading dock or dispatch area to confirm that products meet all customer requirements before shipment.

It checks:

• Product correctness

• Quantity accuracy

• Packaging condition

• Label compliance

• Documentation completeness

• Customer-specific requirements

The goal is simple: Do not ship defects to the customer.

Dock audits are widely used in automotive OEM supply chains, Tier-1 and Tier-2 suppliers, and high-risk industries where shipment errors can cause major disruptions.

Dock Audit Meaning in Manufacturing

In manufacturing terminology, a Dock Audit refers to:

Final inspection of finished goods at the dispatch stage to ensure shipment quality and accuracy.

It is not an acronym and has no official “full form.” The term comes from the physical location — the loading dock.

Why Dock Audit Is Important

A dock audit acts as the last barrier protecting the customer from defects and shipment mistakes.

Key Objectives

• Prevent defective products from reaching customers

• Verify correct part number and revision level

• Ensure proper packaging and labeling

• Confirm shipping documents accuracy

• Avoid wrong quantity dispatch

• Reduce customer complaints and returns

• Support compliance with quality standards

In automotive manufacturing, dock audits are often required by customers as part of supplier quality assurance.

Dock Audit in IATF 16949 and Automotive Industry

Although IATF 16949 does not explicitly mandate dock audits, it emphasizes:

• Customer focus

• Product conformity

• Risk-based thinking

• Prevention of defects

• Control of nonconforming outputs

Dock audits serve as a powerful preventive control aligned with these principles.

Many OEMs require periodic dock audits, especially for safety-critical or high-volume parts.

Types of Dock Audits

Organizations may implement different levels depending on risk.

1. Routine Dock Audit

Performed regularly on random shipments.

2. Customer-Specific Dock Audit

Conducted based on OEM requirements.

3. Containment Dock Audit

Applied after customer complaints or quality issues.

4. Pre-Shipment Audit for New Products

Used during new product launch or process changes.

Dock Audit Checklist (Dispatch Inspection)

A structured checklist ensures no critical verification is missed.

Typical dock audit points include:

Product Verification

• Correct part number

• Revision status

• Visual condition

• Special characteristics marking

• No damage or defects

Quantity Verification

• Correct quantity as per dispatch plan

• Box count accuracy

• Unit count validation

Packaging Verification

• Approved packaging used

• No damaged containers

• Proper sealing

• Cleanliness

Labeling Verification

• Correct customer label

• Barcode readability

• Batch / lot traceability

• Manufacturing date

• Supplier identification

Documentation Verification

• Invoice accuracy

• Packing list

• Test certificates (if required)

• Customer-specific documents

• Transport details

Compliance Checks

• FIFO followed

• Handling instructions applied

• Special storage requirements met

How to Perform a Dock Audit — Step-by-Step Procedure

A systematic approach ensures effectiveness and consistency.

Step 1: Review Dispatch Plan

Check shipment schedule, customer requirements, and product details.

Step 2: Verify Product Identity

Confirm part number, revision level, and product type match the order.

Step 3: Inspect Product Condition

Ensure items are free from defects, contamination, or damage.

Step 4: Verify Quantity

Count boxes and sample units to confirm accuracy.

Step 5: Check Packaging

Ensure packaging meets customer standards and protects the product.

Step 6: Verify Labels

Confirm labels are correct, legible, and properly attached.

Step 7: Review Documentation

Validate shipping documents, certificates, and approvals.

Step 8: Record Audit Findings

Document results using a dock audit form or checklist.

Step 9: Approve or Hold Shipment

Release conforming shipments or stop dispatch if issues are found.

Benefits of Implementing Dock Audit

Organizations gain significant advantages:

- Prevents Customer Complaints

Ensures defects are detected internally rather than by customers.

- Reduces Cost of Poor Quality (COPQ)

Avoids returns, penalties, and rework.

- Improves Shipment Accuracy

Prevents wrong parts or quantities from being dispatched.

- Strengthens Customer Confidence

Demonstrates commitment to quality.

- Supports Continuous Improvement

Audit data helps identify systemic issues.

Common Mistakes in Dock Audits

To be effective, dock audits must avoid these pitfalls:

• Performing only paperwork checks

• Lack of trained auditors

• Infrequent audits

• Ignoring customer requirements

• No follow-up on findings

• Poor documentation

Dock audits should be treated as a preventive control, not a formality.

Dock Audit vs Final Inspection

Although similar, they serve different purposes.

Final Inspection

• Conducted after production

• Focuses on product quality

Dock Audit

• Conducted before shipment

• Focuses on shipment readiness and accuracy

Both are important layers of quality assurance.

Dock Audit in Service and Logistics Operations

Dock audits are not limited to manufacturing. Warehouses, distribution centers, and logistics providers use them to ensure:

• Correct order fulfillment

• Damage-free delivery

• Accurate documentation

• Compliance with shipping standards

Best Practices for Effective Dock Audits

To maximize effectiveness:

• Use standardized checklists

• Train auditors regularly

• Perform random audits

• Focus on high-risk products

• Integrate with quality management system

• Track audit results for improvement

Organizations with mature quality systems treat dock audits as a strategic tool rather than a routine task.

In the fast-paced world of manufacturing, ensuring product quality doesn’t stop once the item leaves the production line. One of the final—but most crucial—steps in the quality control process is the dock audit.

What Does a Dock Audit Include?

A typical dock audit includes checking:

- Product quantity against the shipment documents

- Labeling and barcodes for accuracy

- Packaging quality and damage prevention

- Documentation (e.g., invoice, packing list, etc.)

- Correct loading practices (e.g., FIFO, no damage during transit)

- Visual quality checks for defects or anomalies

- Pallet configuration and weight limits

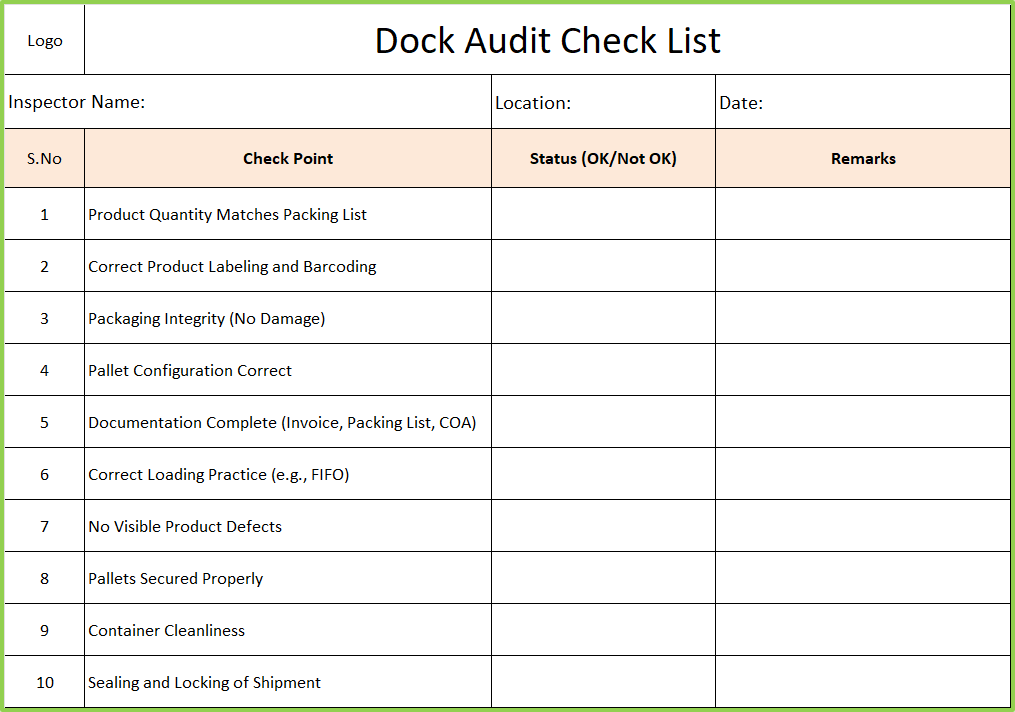

Dock Audit Check Sheet in Excel:

The dock audit checklist contains all the checkpoints as discussed. The quality inspector verifies all the checkpoints before dispatch. Check each point’s status and if found not OK, then write an observation in the remarks.

Note: The Audit checklist can be revised as per the company’s requirements.

Benefits of Performing Dock Audits

- Prevents customer complaints and rejections

- Ensures compliance with quality standards

- Improves traceability and documentation accuracy

- Reduces logistics-related issues

- Boosts customer satisfaction and trust

Frequency and Responsibility

Dock audits can be conducted daily, weekly, or on a per-shipment basis, depending on the criticality of the product. They are typically carried out by quality inspectors or trained shipping personnel.

What to do if the dock audit fails

- Hold the shipment immediately to prevent dispatch.

- Segregate the non-conforming products.

- Record the issue in the audit log or NC register with full details.

- Inform QA, Logistics, and Production teams promptly.

- Perform root cause analysis (e.g., 5 Whys, Fishbone Diagram).

- Take corrective action, such as rework, relabeling, or replacement.

- Conduct a re-audit to verify resolution.

- Approve and release the shipment only after it has been closed.

- Implement preventive actions to avoid recurrence.

- Notify the customer if the issue has already impacted them.

Conclusion

A Dock Audit is a critical final safeguard in the manufacturing supply chain. By verifying product conformity, packaging integrity, labeling accuracy, and documentation completeness at the dispatch stage, it ensures that only quality products reach customers.

In industries such as automotive, where shipment errors can lead to severe consequences, dock audits play a vital role in maintaining reliability, compliance, and customer satisfaction.

Implementing a structured dock audit process not only prevents costly mistakes but also strengthens overall operational excellence. Organizations that consistently perform effective dock audits demonstrate a proactive commitment to quality — building trust, reducing risk, and enhancing long-term business success.

You may also like to read about:

Process audit in a manufacturing industry

Internal Audit Checklist for all departments in a manufacturing industry

Hello there! I just wish to offer you a huge thumbs up for the excellent information you have got right here on this post. I am returning to your blog for more soon.

I savour, result in I discovered exactly what I used to be having a look for. You have ended my 4 day lengthy hunt! God Bless you man. Have a great day. Bye

Very nice write-up. I absolutely appreciate this website. Keep writing!

My brother recommended I might like this blog. He was totally right. This post truly made my day. You can not imagine just how much time I had spent for this info! Thanks!