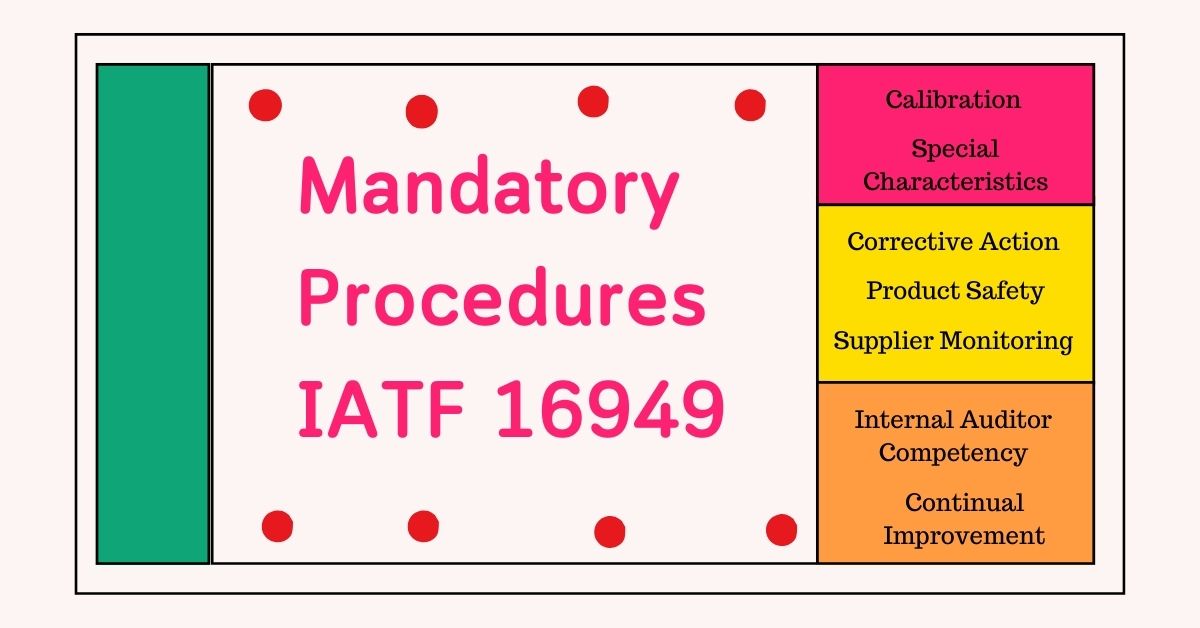

List of mandatory procedures for IATF 16949:

IATF 16949:2016 is the latest version of IATF 16949. There are 21 documented mandatory processes and 282 ‘Shall Requirements’ in IATF 16949. Below are the IATF mandatory procedures.

- List of mandatory procedures for IATF 16949:

- Product Safety Procedure ( 4.4.1.2):

- Calibration Procedure ( 7.1.5.2.1):

- Competence Training ( 7.2.1):

- Internal Auditor Competency ( 7.2.3):

- Employee Motivation ( 7.3.2):

- Engineering Specification ( 7.5.3.2.2):

- Design and Development ( 8.3.1.1):

- Special Characteristics ( 8.3.3.3):

- Supplier Selection ( 8.4.1.2):

- Outsource Process Control ( 8.4.2.1):

- Statutory and Regulatory requirement ( 8.4.2.2 ):

- Supplier Monitoring ( 8.4.2.4):

- Control of Changes ( 8.5.6.1):

- Temporary Change of Process Control ( 8.5.6.1.1):

- Control of Repair & Rework (8.7.1.4 & 8.7.1.5):

- Non-Conforming Product Handling (8.7.1.7):

- Internal Audit ( 9.2.2.1):

- Corrective Action / Problem-solving ( 10.2.3):

- Poka Yoke / Error Proofing ( 10.2.4):

- Continual Improvement ( 10.3.1):

- Mandatory procedures as per IATF 16949 pdf:

| Process Description | Clause No |

|---|---|

| Product Safety | 4.4.1.2 |

| Calibration | 7.1.5.2.1 |

| Competence Training | 7.2.1 |

| Internal Auditor Competency | 7.2.3 |

| Employee Motivation | 7.3.2 |

| Engineering Specification | 7.5.3.2.2 |

| Design and Development | 8.3.1.1 |

| Special Characteristics | 8.3.3.3 |

| Supplier Selection | 8.4.1.2 |

| Outsource Process Control | 8.4.2.1 |

| Statutory and Regulatory Requirement | 8.4.2.2 |

| Supplier Monitoring | 8.4.2.4 |

| Control of Changes | 8.5.6.1 |

| Temporary Change of Process Control | 8.5.6.1.1 |

| Control of Repair | 8.7.1.4 |

| Control of Rework | 8.7.1.5 |

| Non-Conforming Product Handling | 8.7.1.7 |

| Internal Audit | 9.2.2.1 |

| Corrective Action/ Problem-Solving | 10.2.3 |

| Poka Yoke/ Error Proofing | 10.2.4 |

| Continual Improvement | 10.3.1 |

Product Safety Procedure ( 4.4.1.2):

The organization shall have documented processes for manufacturing product safety-related products and manufacturing processes. Check the details about product safety procedures

Calibration Procedure ( 7.1.5.2.1):

The organization shall have a documented process for managing calibration and verification records. So maintain calibration record of all measuring and test equipment and gauges in the organization ( own /customer provided / supplier provided ). For more details about the calibration procedure.

Competence Training ( 7.2.1):

The organization shall define and maintain a procedure for identifying training needs and acquiring competence of all personnel performing activities affecting conformity to product and process requirements. For more details about competence training.

Internal Auditor Competency ( 7.2.3):

The organization shall have a procedure to verify the competence of all internal auditors with any customer-specific requirements. All the QMS auditors, product & process auditors shall have knowledge as applicable:

- All Core Tools ( APQP, PPAP, FMEA, SPC, MSA, CP)

- ISO 9001:2015 / IATF 16949 ( Certified Internal Auditor)

- Customer-specific requirements ( CSR)

- Process approach

- Risk-based thinking

- Auditing knowledge.

Internal auditor competency can be added to the procedure of Internal Audit.

Employee Motivation ( 7.3.2):

The organization shall maintain a procedure to motivate employees to achieve quality objectives, make continual improvements, and create a good work environment. Based on some criteria, employee motivation can be achieved by establishing a suggestion policy, attendance reward, best employee of the month, etc.. Details about employee motivation can be added to the training procedure.

Engineering Specification ( 7.5.3.2.2):

The organization shall have a procedure having the review, distribution and implementation of all customer engineering drawings or any ECN received. Any engineering drawing/specification change should be done within 10 working days. Check the details about Engineering specifications and Engineering change notice ( APQP Procedure)

Design and Development ( 8.3.1.1):

The organization shall establish, implement and maintain a procedure for the design and development process and shall focus on error prevention instead of detection. Follow the procedure for APQP.

Special Characteristics ( 8.3.3.3):

The organization shall establish, document and implement its processes to identify special characteristics including customers specified by the CFT approach. All special characteristics should be cascaded through a special characteristics symbol in FMEA, Control Plan, Operation Standard & Work instruction. For more details about special characteristics, follow the procedure of APQP.

Supplier Selection ( 8.4.1.2):

The organization shall have a procedure for supplier selection. The selection process shall include:

- Supplier quality management system

- Supplier quality and delivery performance

- The volume of the automotive business

- Adequacy of available resources

- Manufacturing capability

For more details about the supplier selection process.

Outsource Process Control ( 8.4.2.1):

The organization shall have a procedure to identify outsourcing processes and to select the control used to verify the conformity of externally provided products, processes and services. For more details about the outsourcing process, follow the procedure of the outsourcing process. Outsourcing activity can be added in the supplier control procedure.

Statutory and Regulatory requirement ( 8.4.2.2 ):

The organization shall document and prepare a procedure to ensure that purchased products, processes and services conform to the applicable statutory and regulatory requirements such as end-of-life vehicle (ELV) testing etc.

Supplier Monitoring ( 8.4.2.4):

The organization shall have a procedure to evaluate supplier performance to ensure conformity with externally provided products, processes and services. Below points must be added in supplier monitoring ( Rating):

- Quality rating of products supplied

- Delivery rating

- Customer disruption

- Premium freight occurrence

- The quality or delivery notification

For Supplier monitoring follow the Supplier control procedure.

Control of Changes ( 8.5.6.1):

The organization shall have a procedure to control and react to changes that impact product realization. The effect of any change on the customer or supplier shall be assessed. The organization shall:

- Validate the change before implementation.

- Define a control plan to ensure compliance with customer requirement

- Maintain verification and validation record

- FMEA for risk analysis

The ECN activity can be added to the APQP procedure.

Temporary Change of Process Control ( 8.5.6.1.1):

The organization shall identify, document and maintain a list of the process control including inspection, measuring test and error-proofing devices. It includes the primary process control and approved alternate process control for contingency. For more details about the Temporary change process control procedure.

Control of Repair & Rework (8.7.1.4 & 8.7.1.5):

The organization shall have a documented rework & repair control procedure and other relevant documented information to verify compliance with the original specification. Also the organization shall do a risk analysis of the rework and repair process before the rework decision. The organization shall retain a record of the disposition of rework & repair products including quantity, disposition, disposition date and traceability information.

Non-Conforming Product Handling (8.7.1.7):

The organization shall have a procedure for the disposition of nonconforming products which can not be reworked or repaired. The organization shall verify the product to be scraped before disposal. Follow the procedure of Non-conforming product handling and red bin analysis.

Internal Audit ( 9.2.2.1):

The organization shall have an internal audit procedure. It includes the internal audit program that covers the internal quality management system audit of all departments, manufacturing product and process audit. For more details about the internal audit procedure.

Corrective Action / Problem-solving ( 10.2.3):

The organization shall have a procedure for corrective action. It includes:

- Corrective action for in-house complaints, customer complaints, breakdown or audit non-conformity.

- Containment action

- Root cause analysis

- Systematic corrective action

- Verification of corrective action implementation

- Standardization

For more details about corrective action, Follow the procedure for complaint handling.

Poka Yoke / Error Proofing ( 10.2.4):

The organization shall have a documented process to determine the use of the appropriate error-proofing methodology. Prepare a list of all poka-yoke used in the organization and a poka-yoke verification check sheet. Add detail of poka-yoke in FMEA and frequency of checking in control plan & operation standard. Keep challenge parts for verification of poka-yoke.

Continual Improvement ( 10.3.1):

The organization shall have a documented process or procedure for continual improvement. Identify the methodology used, objectives, measurement, effectiveness and record in Kaizen format. Prepare a manufacturing process improvement action plan by focusing on reducing process variation and waste. Continual improvement can be on productivity, quality, cost, defect reduction & safety (PQCDS).

Dear team ,

Thanks for your support to share the knowledge .it really helps to understand gap based on requirement.

kindly update procedure for rework and repair product that will be great help to understand the things indepth.

https://learnqctools.in/procedure-for-rework-repair

Dear sir

Thanks for Uploading …

Regards

Karthik M

Dear Team ,

Kindly share the Alarm & Escalation Policy procedure .

Regards

Karthik M

Dear team ,

Thanks for your support to share the knowledge .

Regard’s

Patil DM