Purpose:

To ensure that the personnel performing work affecting product quality are competent based on appropriate education, training, skill & experience. Also to motivate employees to achieve quality objectives, continual improvement and create an environment to promote quality culture and innovation.

Scope:

This procedure relates to all personnel carrying out activities affecting the quality of products and related services.

Responsibility for training :

The overall responsibility of maintaining the effectiveness and implementation of this procedure lies with the HR Head.

Training procedure:

Training needs identification (TNI) :

Competency needed for different employees of each department is determined on the “Competence Level Requirement Sheet” and training needs are developed for each employee in the “Training Need Identification Form”. Staff training is identified by the HOD and by himself. Also, review training topics as per the needs of the respective department.

The training need of associates is identified by the supervisor through verbal interviews and observation. The topic for training should be selected as per need required based on their working in the respective department. Also review training needs ( Training Topics) each year as per skill required based on work, skill evaluation & skill level criteria.

Training Topics :

Training topics for staff can be selected from the list below:

- Statistical Process Control (SPC)

- Measurement System Analysis (MSA)

- Advanced Product Quality Planning (APQP)

- Production Part Approval Process (PPAP)

- Failure mode effects and analysis (FMEA)

- 7 QC Tools

- ISO 9001 / IATF 16949

- Cost of Poor Quality (COPQ)

- 8D / CAPA

- Product & process audit

Training topics for associates can be selected from the list below:

- 5S

- Suggestion & Kaizen

- FIFO

- Poka Yoke

- Identification & Packing

- Fire & Safety

- 4M Change

- Safety PPE

- Machine check sheet

- Operation standard

- Material Handling

- Abnormal situations

Training Method:

Based on training needs the “Annual Training Plan” is prepared and training is imparted as per the plan by trainers identified, including external trainers or at the external training center. All participants’ presence is recorded in the “Training Attendance Record”. Training effectiveness is verified by the trainer after one month. The training effectiveness record is maintained in the “Training Effectiveness Record. If the number of participants is absent on the scheduled training date, then make a plan for those training topics and deliver training within one month.

Training feedback is taken on the same day. Training effectiveness for staff is evaluated by HOD based on improvement in their work. There should be a training room ( DOZO ) in the company for providing training. Arrangements for re-training are made for those employees whose effectiveness is found less than 60% within a week.

Training Module cum Training Record Format:

New Employee Training:

All new entrants are given induction training by the concerned HOD to be aware and familiar with the quality management system and the consequences of nonconformity to quality requirements for customers. Cover all employees’ company roles and contracts.

All employees are made aware of the technological changes. Provide training as per the training plan based on TNI. Also provide training to the new joinee as per the new joinee training record on the following topics –

- Company profile

- 5S

- Safety

- Part Handling

- Work instruction

- Process awareness

- Product awareness

- Document knowledge

The above training is provided to achieve quality objectives through a specified designated training program. ( Dozo Training program)

New Joinee training shall be delivered on the same day. The first-day production quantity will be verified by the concerned supervisor. The new joinee will work under the supervisor’s observation for one week and maintain the record in the new joinee’s production monitoring record. For a new joinee in PDI, conduct poison tests and maintain inspection records for one week. After one week concerned department head evaluates the skill through a level-wise questionnaire sheet as per skill evaluation criteria and updates the skill matrix within a month.

New Operator training criteria:

New Joinee training shall be delivered on the same day as per the defined criteria for the experienced operators and fresher operators. The respective operator can achieve the desired skill level after meeting the criteria defined below.

| Experienced operator | Fresher Operator | Skill level |

|---|---|---|

| One day | Two days | L-1 |

| Three days | one week | L-2 |

| One Week | Two week | L-3 |

| Six Month | Six Month | L-4 |

Prepare a Skill matrix for the standard room person. Provide training related to equipment and the related field as per the training plan. Also maintain training records with effectiveness as per the training provided.

Conduct Operator Observance for all operators covering all operators & both shifts from each department if any operator does not qualify, then provide training on the same day & check the effectiveness as per the criteria.

Conduct a Poison Test as per the poison test WI for all final inspectors as per the plan to check that inspectors are capable of detecting the defect. If an inspector is not qualified, then provide training on the same day & take the poison test after training.

On-the-job training is provided to the personnel in any new or modified job affecting product quality.

The process is established to motivate employees to achieve quality objectives to make continual improvements. This process includes the promotion of quality and technological awareness throughout the organization.

Multi-Skilled Operators:

Select some operators as per the requirement for multi-skilling in each department. Provide training to them from level 2 and upgrade them. The target should be to upgrade them to at least level 3 so that he can work independently.

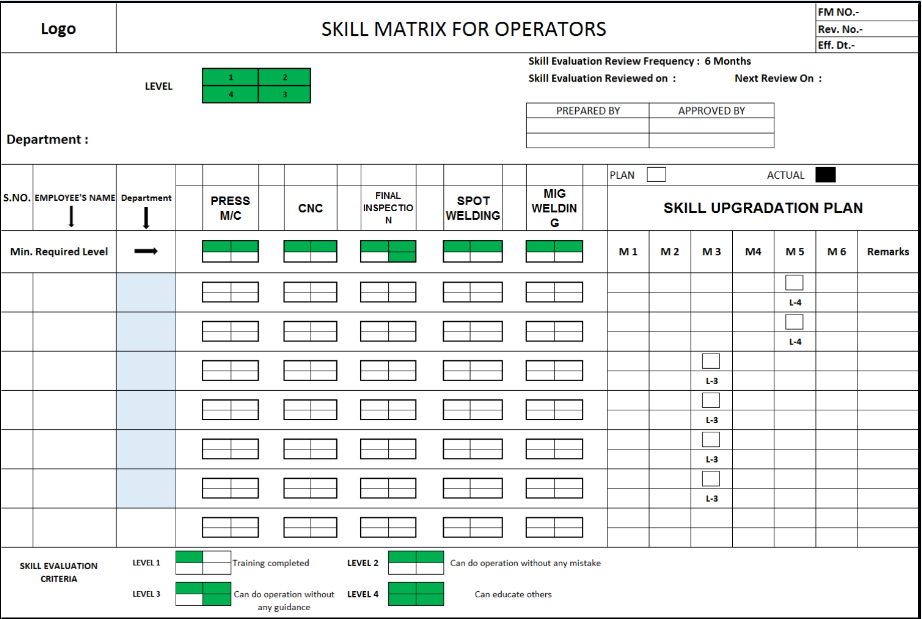

Skill Matrix:

For Operators and inspectors, a Skill Matrix is to be prepared. In the skill matrix, defined skill level is defined as per the skill evaluation criteria. Take level-wise theoretical question papers and practical evaluations ( Qualitative and quantitative). Then update the skill matrix and display it in the respective departments. During skill evaluation, if the skill is found less than the previous level, make a plan for re-training within a week. Skill evaluation and skill matrix shall be reviewed after six months.

Skill Matrix Excel template:

Skill upgradation:

Make a plan for the skill upgradation of each employee in each department. The target for upgradation should be at least ‘level 3’, which means ‘can do operation independently’. After that, we can plan only some of the selected operators to level 4 as per the requirement.

New Product Training:

The development Head/QA Head will provide training to all concerned persons such as Operators, Supervisors, and Inspectors about Product and Customer-specific requirements before the SOP of the product.

Education/ training procedure questions as Mace/Maruti VSA Check sheet:

Do you clarify the department in charge of promoting quality education and implementing education based on an annual plan? Are records of education kept?

| Sub Question |

|---|

| Is the training procedure is available or not? |

| Training needs identification done; Y/N |

| Training plan made as per above need (TNI): Y/N |

| Training Plan vs Actual Status |

| Training content is to be checked |

| Effectiveness of training is checked; Y/N (Effectiveness for Operators/Staff) |

| New operator training given / Induction Training Record: Y/N (standard induction training program available and followed) (above requirements must be checked with one example for operator and staff wherever applicable) |

| Training Plan for operators for awareness training |

Do you define and implement the skill evaluation of the operator to determine whether the operator can work without surveillance? (e.g. acceptable revel/evaluation frequency/ evaluation method)

| Sub Question |

|---|

| For each operator, skill evaluation is done: Y/N (applicable for Production, Tool Room and Inspection) |

| For each skill level (e.g. defining an operator at Level 1,2,3,4), specific criteria is made and followed. (implementation check) |

| Minimum skill level to perform any operation: defined and followed check |

| Availability of Skill Matrix on the shop floor (all operators to be included) |

Education for Managers/Inspectors/ Special operators

Do you periodically monitor the skills of certified operators and follow up to improve their skills?

| Sub Question |

|---|

| Skill evaluation frequency using criteria followed above (clause no 5.1.2): Quarterly/half yearly (skill evaluation must be done at least 2 times/year) |

| For the QA inspector, the Poison test is done: Y/N (Frequency) |

| Skill upgradation plan for Operators (in case the skill level is reduced) (plan to be available in the skill matrix) |

You may also like to read about below topics:

- Operator observance process in a manufacturing industry.

- Poison Cake Test for quality inspectors.

Great post. I was checking continuously this blog and I’m impressed! Very helpful info specially the last part 🙂 I care for such information a lot. I was seeking this certain info for a long time. Thank you and good luck.