PDCA Cycle

It is a cycle of continuous improvement. The meaning of PDCA is Plan, Do, Check & Act. The PDCA cycle is also known as the Deming Cycle.

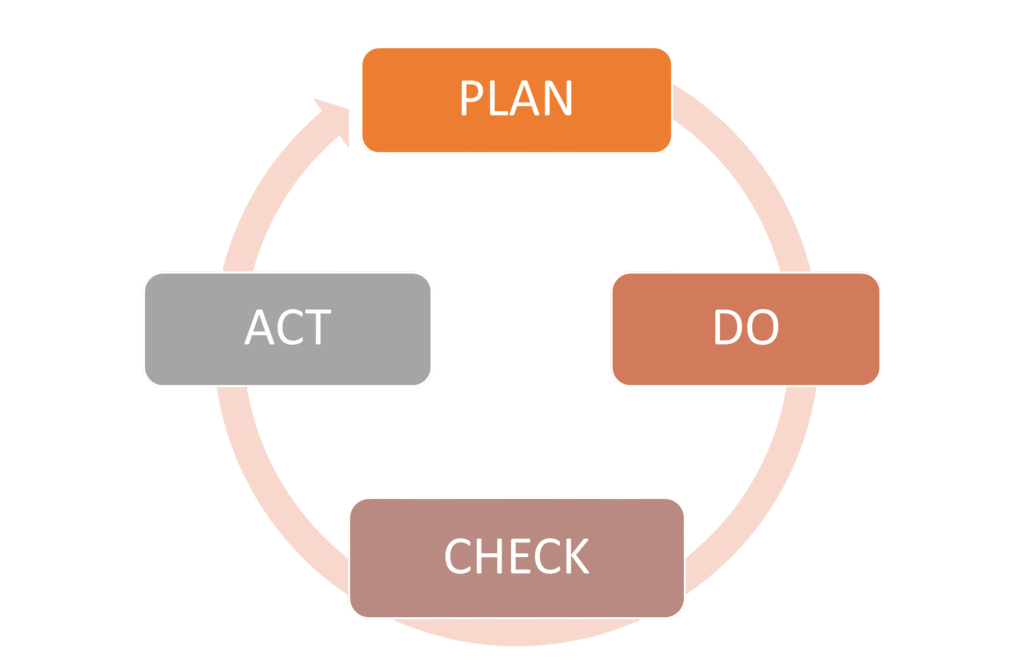

What are the steps of the PDCA Cycle?

There are 4 steps in the PDCA cycle.

1. PLAN

2. DO

3. CHECK

4. ACT

PLAN :

Image from Pixabay

Identify the Problem :

- Identify the problem that needs to be solved

- Make a problem statement to define the problem

- Make SMART goals ( Specific, Measurable, Achievable, Realistic & Time-bound)

- Identify the team.

Analyze the Problem:

- Check the process flow of the complete process or system.

- Brainstorm for the possible causes.

- Analyze data to validate the root cause.

- Revise the problem statement if required.

Tools used for the Plan step :

- Process Flow Diagram

- Process Mapping

- Cause & Effect diagram

- Pareto Chart

DO :

Image from Pixabay

Develop Solutions:

- Do that activity or experiment

- Design of experiment (DOE)

- Discuss with the team for a solution to get the right solution.

Implement the solution :

- Implement the solution on a trial basis.

Tools used for DO steps :

- Cross-Functional Team (CFT)

- Design of Experiment (DOE)

- Provide training about the work

CHECK :

Image from Pixabay

Verify the results:

- Analyze the result of the solution

- Validate the result

Achieve the required Goal :

- If the goal has been achieved, then go to ACT

- If the goal is not achieved, go to PLAN and revise the problem/actions.

Tools used for CHECK steps:

- Control Charts

- Key performance indicator (KPI)

- Process observation

ACT :

Image from Pixabay

Implement the Solution :

- Identify the systematic changes.

- Training needs identification (TNI)

- Plan continuous monitoring of the solution.

- Do Kaizen in the process.

Tools used for ACT steps:

- Standardization of work & process

- Do Poka Yoke

- Process Mapping

- Provide regular training

You may like to read about other topics:

How to calculate Cycle time and Takt time for line balancing