Introduction

VDA 6.3 is one of the most important process audit standards used by automotive suppliers to ensure consistent quality and performance. This guide explains the complete VDA 6.3 process audit approach, including the audit checklist, scoring system, and supplier requirements. We’ll also cover the latest VDA 6.3 process revision updates so you can prepare for audits effectively and improve your process ratings.

This guide explains the complete VDA 6.3 audit process, its key requirements, and how suppliers can prepare and perform well in these audits. Whether you’re a quality manager, process engineer, or supplier auditor, this post will help you understand every aspect of the VDA 6.3 system simply and practically.

What is VDA 6.3?

VDA 6.3 is a process audit standard developed by the German Automotive Industry Association (VDA). It focuses on evaluating and improving process effectiveness and capability throughout the product lifecycle — from project management to production and customer service.

Unlike system audits (like ISO 9001 or IATF 16949), VDA 6.3 audits focus on process-level performance — ensuring that each process step contributes to consistent product quality and customer satisfaction.

Why is VDA 6.3 Important for Suppliers?

For automotive suppliers, VDA 6.3 compliance isn’t just optional — it’s often a mandatory requirement by German OEMs and Tier-1 customers.

Here’s why it matters:

- ✅ Demonstrates your process capability and quality assurance

- ✅ Builds customer confidence and improves supplier ratings

- ✅ Reduces defects, rework, and warranty issues

- ✅ Ensures alignment with IATF 16949 and core tools (APQP, PPAP, FMEA)

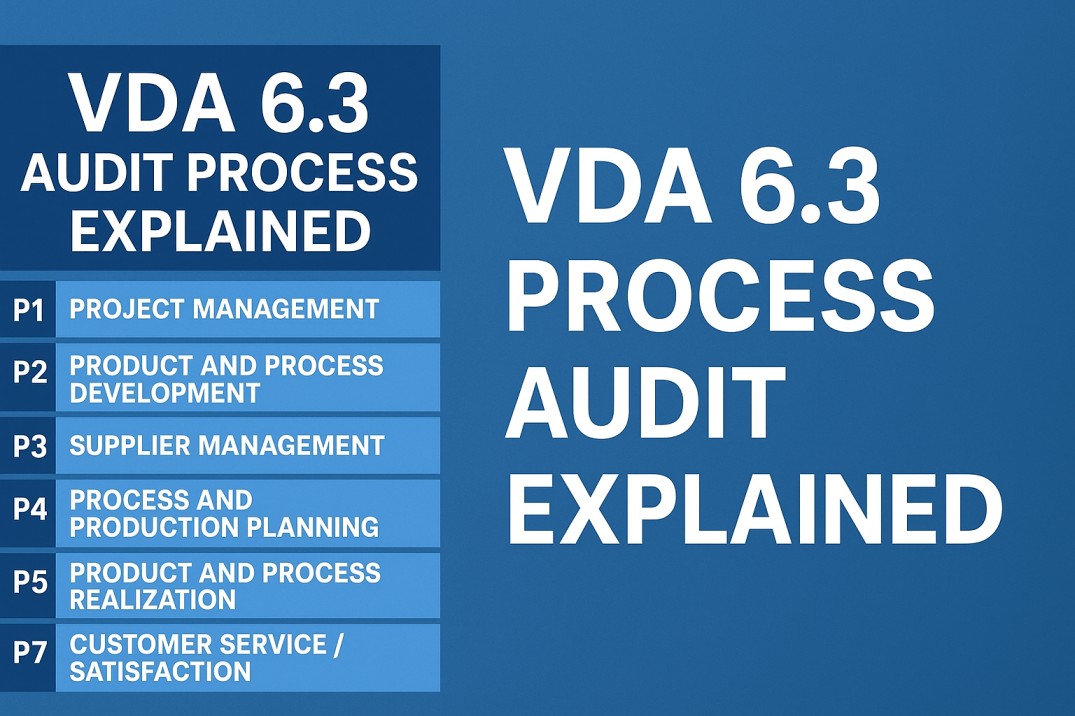

Scope of VDA 6.3 Process Audit

The VDA 6.3 process audit covers seven main process elements, identified as P1 to P7. Each element evaluates a specific stage in the manufacturing or development process.

| Element | Process Area | Key Focus |

|---|---|---|

| P1 | Project Management | Planning and control of new projects |

| P2 | Product and Process Development | Design and validation activities |

| P3 | Supplier Management | Evaluation and control of sub-suppliers |

| P4 | Process and Production Planning | Readiness for series production |

| P5 | Product and Process Realization | Production control and validation |

| P6 | Customer Service / Satisfaction | Field performance and feedback |

| P7 | Process Analysis / Continuous Improvement | Root cause and improvement actions |

Each process element is scored and weighted to calculate an overall audit rating.

VDA 6.3 Scoring System Explained

The VDA 6.3 audit uses a point-based scoring system where each question is rated as:

- 10 points: Full compliance

- 8 points: Minor deviation

- 6 points: Partial compliance

- 4 points: Major deviation

- 0 points: Non-compliance

The overall score (%) determines the audit result:

| Score (%) | Grade | Meaning |

|---|---|---|

| ≥ 90% | A | Fully compliant – process capable |

| 80%–89% | B | Conditionally compliant – improvement required |

| < 80% | C | Not compliant – immediate action needed |

Detailed Explanation of Each Process Element

P1 – Project Management

Ensures projects are planned and executed effectively.

Key checks:

- Clear project goals, timelines, and responsibilities

- Risk analysis and mitigation plans

- Customer communication and milestone tracking

Tip: Use APQP principles and maintain a live project tracker.

P2 – Product and Process Development

Evaluates whether design and process development meet customer needs.

Key checks:

- Feasibility analysis before acceptance

- FMEA (Design and Process) completion

- Validation and testing reports are available

Tip: Keep DFMEA and PFMEA linked and updated for traceability.

P3 – Supplier Management

Focuses on how well you manage your sub-suppliers.

Key checks:

- Supplier evaluation and approval process

- Incoming material inspection and feedback loop

- Supplier performance monitoring

Tip: Maintain supplier rating data and audit records.

P4 – Process and Production Planning

Reviews readiness for mass production.

Key checks:

- Control plan, layout, and flow diagram finalized

- Capacity verification and contingency plans in place

- Production tooling and gauges validated

Tip: Link APQP and PPAP documents to show preparedness.

P5 – Product and Process Realization

Covers the execution of production processes.

Key checks:

- Work instructions and visual standards are available

- Operator training records are maintained

- Real-time process control and reaction plan

Tip: Regularly conducting layered process audits helps maintain compliance.

P6 – Customer Service

Evaluates field performance and after-sales support.

Key checks:

- Complaint handling (8D Reports, CAPA)

- Warranty data analysis and improvement actions

- On-time delivery and responsiveness

Tip: Keep track of trend data on customer complaints to demonstrate improvement.

P7 – Process Analysis and Improvement

Focuses on continuous improvement and root cause correction.

Key checks:

- Implementation of corrective and preventive actions (CAPA)

- Kaizen, 5S, and Lean improvement initiatives

- Periodic management review and action tracking

Tip: Maintain an improvement matrix showing year-on-year progress.

Documents Required for VDA 6.3 Audit

Here’s a list of essential documents suppliers should keep ready:

- APQP documentation (timing plan, feasibility, risk assessment)

- DFMEA, PFMEA, Control Plan, Work Instructions

- Supplier evaluation records

- Process flow diagram and layout

- Production and inspection data

- 8D Reports, CAPA records, and customer feedback

- Internal audit and management review reports

Pro tip: Keep all documents in a single digital or binder-based “VDA 6.3 File” to save time during audits.

How to Prepare for a VDA 6.3 Audit: Understand the audit scope – Review P1 to P7 questions.

- Conduct an internal VDA 6.3 self-audit using the same checklist.

- Identify gaps and plan corrective actions.

- Train process owners and engineers in the VDA 6.3 methodology.

- Ensure traceability of all records and documents.

- Review past audit findings and ensure closure evidence is available.

Tip: You can use Excel-based self-assessment tools to rate your processes before the external audit.

Common Nonconformities found in VDA 6.3 Audits

- Missing linkage between DFMEA and PFMEA

- The control plan does not reflect process changes

- Supplier evaluation is not regularly updated

- Lack of a reaction plan for process deviations

- Training and competency records are incomplete

- Inadequate evidence for CAPA implementation

How to avoid these:

Regularly update process documentation, conduct internal process audits, and ensure every engineer understands the purpose of each VDA 6.3 question.

VDA 6.3 vs IATF 16949

While both aim for process quality and continuous improvement, their focus areas differ:

| Aspect | VDA 6.3 | IATF 16949 |

|---|---|---|

| Type | Process Audit | System Audit |

| Objective | Evaluate process capability | Evaluate management system compliance |

| Focus | Project, process, supplier, production | Overall QMS structure |

| Frequency | Typically annual or customer-driven | Scheduled per internal audit plan |

Both standards complement each other — implementing VDA 6.3 strengthens your IATF compliance and customer satisfaction.

Benefits of Implementing VDA 6.3

- Improved process performance and defect reduction

- Enhanced visibility of supplier quality performance

- Stronger customer relationships and trust

- Early detection of process risks

- Structured approach to continuous improvement

Conclusion

VDA 6.3 is more than just a checklist — it’s a strategic framework for process excellence. Suppliers who understand and apply its principles consistently see measurable improvements in performance, customer satisfaction, and audit scores.

If your organization aims to become a preferred supplier to global automotive brands, mastering VDA 6.3 audits is essential.

Start by training your team, organizing your documentation, and aligning your processes with P1–P7 elements.

Remember, VDA 6.3 is not about passing an audit — it’s about building a culture of quality and continuous improvement.

Frequently Asked Questions (FAQs) on VDA 6.3 Process Audit

1. What is the VDA 6.3 Process Audit?

VDA 6.3 is a process-based audit standard developed by the German Automotive Industry Association (VDA) to assess and improve quality in manufacturing and supplier processes. It helps identify risks and ensure consistent product quality.

2. Why is VDA 6.3 important for suppliers?

It is important because many OEMs, especially German car manufacturers, require their suppliers to meet VDA 6.3 standards. It ensures process stability, risk reduction, and customer satisfaction.

3. Who can perform a VDA 6.3 audit?

A certified VDA 6.3 auditor, trained and approved by the VDA-QMC (Quality Management Center), can perform the audit. Many organizations also train internal auditors for pre-assessments.

4. What are the main elements of VDA 6.3?

VDA 6.3 is divided into key process elements including project management, product and process development, supplier management, series production, and customer service.

5. How is VDA 6.3 different from IATF 16949?

IATF 16949 is a management system standard for automotive quality systems, while VDA 6.3 is a detailed process audit guideline focusing on how each process is controlled, measured, and improved.

6. How often should VDA 6.3 audits be performed?

Typically, suppliers conduct internal VDA 6.3 audits annually, and external audits may be scheduled by customers or certification bodies based on risk or performance.

7. What is the scoring system in VDA 6.3?

Auditors score each question on a scale (0, 4, 6, 8, 10) depending on compliance. The total score determines the rating: A (≥90%), B (80–89%), or C (<80%).

8. How can I prepare for a VDA 6.3 audit?

Start by reviewing your process documentation, FMEA, control plans, and production records. Conduct internal mock audits and close gaps before the main audit.

You may like to read about: