The 3G Principle—Genchi Genbutsu, Gemba, and Genjitsu—is one of the strongest foundations of Japanese manufacturing. It is widely used in the Toyota Production System (TPS), lean manufacturing, and automotive industries for accurate decision-making and root cause identification. When any abnormality, defect, breakdown, or customer complaint appears, leaders instruct teams to “Go to the Gemba and see the real facts.”

In many factories, engineers spend hours analysing problems in conference rooms, but real-quality issues live on the shop floor. The 3G Principle ensures that engineers, supervisors, auditors, and managers do not assume—they observe. This approach eliminates guesswork and builds a culture of fact-based problem solving.

This article explains the 3G principle in detail, covering its meaning, Japanese full forms, benefits, shop-floor examples, and how 3G supports quality tools such as Control Plan, PFMEA, 7 QC Tools, Process Audit, and Root Cause Analysis.

- What Is the 3G Principle in Manufacturing?

- 3G Full Form: Meaning of the Japanese Terms

- Why the 3G Principles are important in Lean and QMS

- How to Apply the 3G Principle on the Shop Floor

- 3G Principle Example in the Automotive Industry

- 3G and Gemba Walk: A Strong Connection

- How 3G Improves Process Audits

- 3G Principle vs 5G Principle

- How 3G Supports Root Cause Analysis (RCA)

- Using 3G for Corrective and Preventive Actions (CAPA)

- 3G in New Product Development (APQP)

- 3G in Modern Digital Manufacturing

- Frequently Asked Questions

- Conclusion

What Is the 3G Principle in Manufacturing?

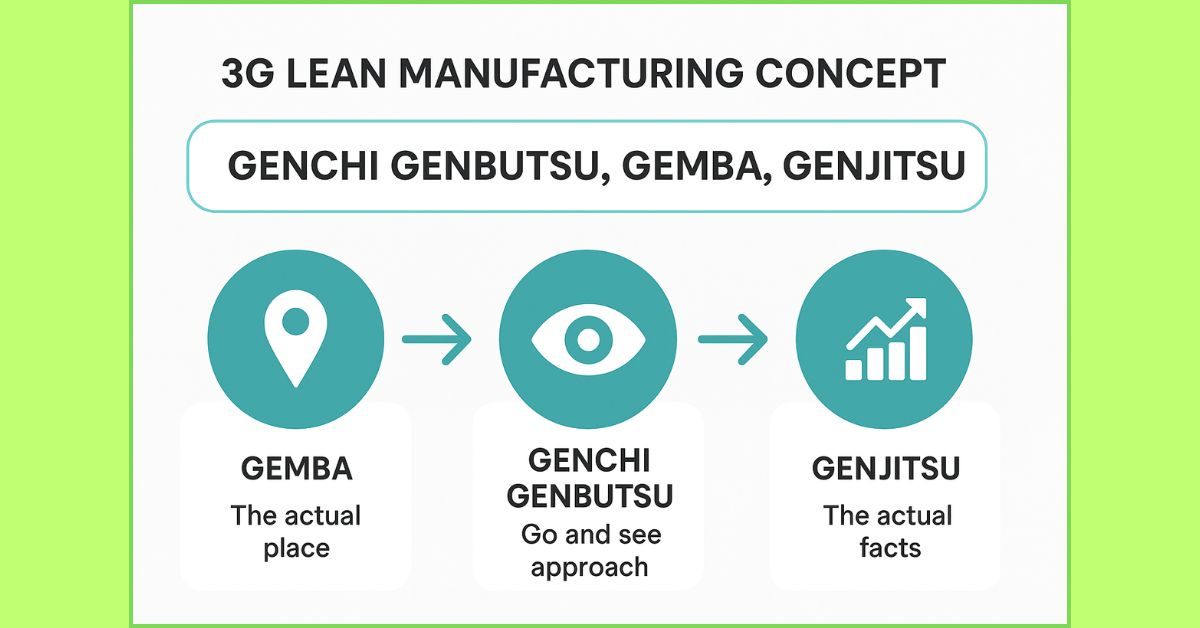

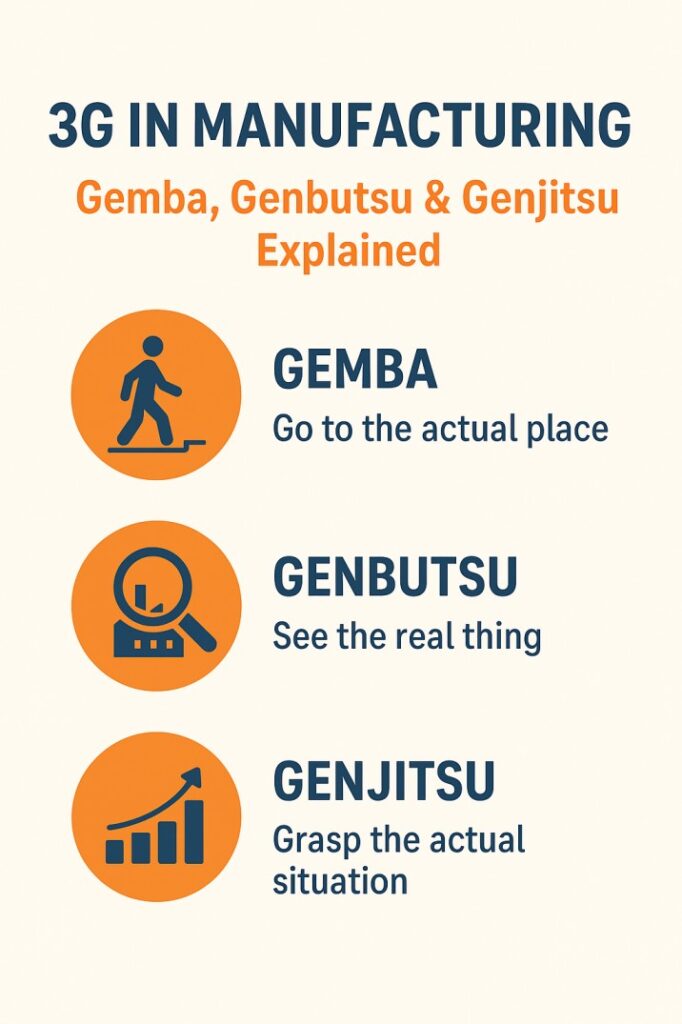

The term 3G represents three Japanese words that begin with “G”:

1. Gemba – The actual place

2. Genchi Genbutsu – Go and see the actual item or situation

3. Genjitsu – The real facts and data

In simple words, the 3G concept means:

Go to the actual place → See the actual condition → Use facts for decision-making.

This is essential in manufacturing because parts, machines, tools, human behaviour, and environmental conditions change continuously. Observing reality ensures better accuracy in analysis.

3G Full Form: Meaning of the Japanese Terms

Many people search for “3G full form” or “3G full form in Japanese,” so here is the correct explanation:

Gemba (現場) – The real place

This is the physical location where the work happens—assembly line, welding station, CNC area, paint booth, inspection cell, warehouse, etc. Gemba walks become powerful when combined with standards like Work Instructions and Standard Work.

Genchi Genbutsu (現地現物) – Go and see the actual thing

Rather than relying on someone’s explanation, inspect the actual defective part or process condition. For example, touching a burr on the component is more informative than seeing a picture.

Genjitsu (現実) – Real facts

This represents actual data such as torque readings, cycle times, pressure values, SPC readings, and process parameters defined in the Control Plan. Genjitsu helps validate what you observed.

Together, these three Gs create a strong foundation for quality improvement.

Why the 3G Principles are important in Lean and QMS

Most failures in problem-solving occur because actions are taken based on assumptions or incomplete information. The 3G principle eliminates this gap.

Benefits of 3G:

- Correct identification of the root cause

- Reduced defects and rework

- Improved operator understanding

- Better audit findings

- Strong linkage between the Control Plan and real operations

- Quick identification of abnormalities

- Sustainable corrective actions

- Fewer customer complaints

3G builds a habit of verifying facts before making decisions.

How to Apply the 3G Principle on the Shop Floor

Here is a step-by-step method to implement 3G:

Step 1: Go to Gemba

Visit the place where the issue occurred. Observe the environment, operator motion, machine condition, and process flow. Compare the observation with the Process Audit checklist.

Step 2: Conduct Genchi Genbutsu

Inspect actual defective parts. Measure the defect using gauges. Check tools, jigs, fixtures, and handling methods.

Step 3: Validate Genjitsu

Collect real data—dimensions, SPC charts, tool wear, machine parameters, and readings defined in the Control Plan and PFMEA. This confirms factual accuracy.

Step 4: Compare Actual vs Standard

Use Work Instructions, Flow Diagram, PFMEA, and Control Plan to verify deviations. This helps identify process gaps.

Step 5: Conduct Root Cause Analysis

Use tools like 5 Why Analysis, Fishbone Diagram (Cause and Effect), and 8D Problem Solving to derive logical conclusions.

Step 6: Implement and verify corrective actions

Apply changes and confirm them through Process Audit or Control Charts / SPC.

3G Principle Example in the Automotive Industry

Problem:

Customer complaint regarding dent marks on a press shop component.

Gemba Visit:

Supervisors and engineers visit the press line.

Genchi Genbutsu:

They examine actual rejected parts. Dent patterns indicate foreign particle entrapment.

Genjitsu:

A check reveals that the cleaning air nozzle’s pressure has dropped. SPC trend in the cleaning station shows variation, but was not escalated. Preventive maintenance was pending.

Root Cause:

Improper cleaning due to pressure drop.

Corrective Action:

Nozzle replaced, periodic check added to Control Plan, and operator training updated in Standard Work.

This example shows how 3G ensures factual root cause detection.

3G and Gemba Walk: A Strong Connection

Gemba Walk is a structured form of the Gemba element of 3G. While 3G focuses on going, seeing, and understanding, Gemba Walk adds:

- Purpose

- Checklist

- Leadership observation

- Standardized auditing

You can strengthen this section by linking to your Gemba Walk article.

How 3G Improves Process Audits

Process Audits often fail when auditors:

- Only check documents

- Rely on operator statements

- Do not compare actual vs standard

3G ensures effective Process Audit by:

- Verifying real shop-floor practices

- Checking actual inspection methods

- Comparing the Control Plan vs the actual parameters

- Linking audit findings with PFMEA risks

This makes audit reports stronger and more practical.

3G Principle vs 5G Principle

Although both concepts come from Japanese industry practices, their objectives differ.

| Feature | 3G Principle | 5G Principle |

|---|---|---|

| Purpose | Problem solving & RCA | Identify abnormalities systematically |

| Focus | Real place, real part, real facts | Genba, Genbutsu, Genjitsu, Genri, Gensoku |

| Usage | Quality & Lean problem solving | Observation & standardization |

3G is action-driven, whereas 5G is structured review-oriented.

How 3G Supports Root Cause Analysis (RCA)

Most RCA failures happen because analysts skip Gemba, leading to incorrect conclusions. 3G strengthens RCA because:

- Genchi Genbutsu provides evidence

- Genjitsu confirms data validity

- Gemba reveals behavioural and process deviations

This improves tools like:

- Fishbone Diagram

- 5 Why Analysis

- 7 QC Tools (especially Check Sheet, Pareto Chart, Histogram)

- 8D Problem Solving

Using 3G for Corrective and Preventive Actions (CAPA)

Effective corrective actions must be based on:

- Actual part condition

- Actual process data

- Actual observation

3G ensures CAPA effectiveness by validating data with Genjitsu and verifying process conditions with Process Audit and Control Charts.

3G in New Product Development (APQP)

During APQP stages, 3G helps in:

- Understanding prototype issues

- Verifying inspection methods

- Checking operator understanding

- Confirming Control Plan and PFMEA requirements

- Ensuring fixture readiness

This reduces problems during PPAP submission.

3G in Modern Digital Manufacturing

Even with IoT, MES, digital twins, and live dashboards, physical observation is irreplaceable because digital systems cannot detect:

- Unusual noise

- Operator fatigue

- Unsafe handling

- Wrong posture

- Poor 5S practices

Digital tools support Genjitsu, but Gemba and Genchi Genbutsu must still be performed manually.

Integrating 3G with Broader Lean Tools

- 3G supports the Kaizen philosophy by providing real-world insights for continuous, incremental improvements.

- Lean’s emphasis on eliminating waste and streamlining flow is reinforced by 3G’s focus on real-time observation and factual analysis.

- Combine 3G with visual boards and PDCA cycles for more structured and data-driven improvements.

Frequently Asked Questions

What is the 3G concept in manufacturing?

A Japanese method for problem solving using Gemba, Genchi Genbutsu, and Genjitsu.

What is the 3G full form in Japanese?

Gemba (actual place), Genchi Genbutsu (go and see), and Genjitsu (real facts).

Why is 3G important?

It ensures accurate decision-making, reduces assumptions, and improves RCA.

Is 3G used in Lean?

Yes, it is a core principle of TPS and supports tools like Gemba Walk, Kaizen, and Process Audit.

What is an example of 3G?

Visiting a machine where a defect occurred, inspecting actual rejected parts, and collecting real data to identify the cause.

Conclusion

The 3G principle is simple yet powerful. Whether solving a defect, conducting a Process Audit, preparing a Control Plan, or performing RCA, always follow the sequence:

Go to Gemba → See the actual part → Collect real facts → Take action.

Companies that adopt 3G achieve stronger processes, fewer defects, and higher customer satisfaction. When practised daily, it builds a culture of truth-based decision-making.

👉 Start applying the 3G principle in your workplace today to uncover hidden problems, engage your teams, and drive sustainable improvement.