Introduction

Artificial Intelligence (AI) is changing how quality management works. It helps companies find problems early, predict defects, improve supplier quality, and save time during audits. However, many companies find it difficult to start because of unclear goals, poor data, or a lack of training.

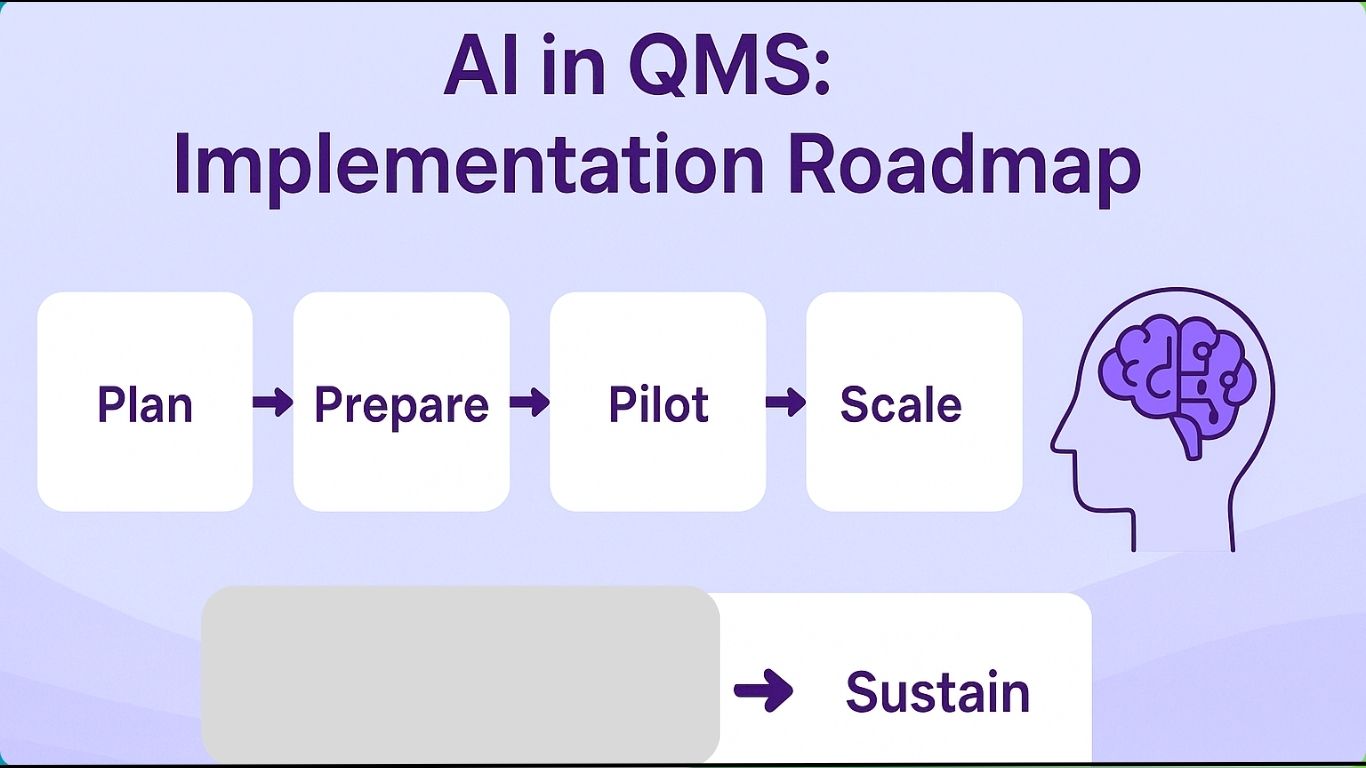

This simple guide explains how to bring AI into your QMS step by step — from planning to real results. You’ll also see a case study from a company showing how predictive analytics reduced rejects and improved CAPA closure time.

Step 1 — Plan and Get Support

Before starting, make sure management supports the idea and teams understand the goals. Create a small team with members from quality, production, data, and IT.

Key actions:

- Set clear goals such as reducing defects or speeding up CAPA closures.

- List your data sources — machine logs, inspection data, NCRs, supplier records.

- Choose one or two easy use cases for pilot testing.

Step 2 — Prepare Data

AI is only as good as the data it learns from. Review your data and fix quality issues like missing values or wrong timespan.

Tips:

- Use data from sensors, SPC charts, CAPA logs, and supplier records.

- Check for gaps and fix them early.

- Start small — you can add more data later.

Step 3 — Run a Pilot Project

Choose one or two pilot projects that can show visible results in a few weeks.

Examples:

- Detecting unusual machine behavior using sensor data.

- Predicting which parts may fail based on process data.

- Using text analysis (NLP) to sort NCRs automatically.

Steps for the pilot:

- Prepare and clean the data.

- Choose simple and explainable models such as decision trees or XGBoost.

- Measure results using both technical metrics and business metrics (like reduction in defects).

- Let experts review model results before taking automatic actions.

Measure success by: precision, recall, number of true alerts, and reduction in rejects.

Step 4 — Scale and Integrate

Once your pilot works, connect it with your main QMS system. Build dashboards to show alerts and results.

What to do:

- Automate retraining of models every few months.

- Integrate alerts into your normal NCR or CAPA process.

- Add model logs and reports for audit trails.

Tools you can use: Python for modeling, Power BI or Grafana for dashboards, and MLflow for tracking models.

Step 5 — Train People and Monitor Results

AI success depends on people trusting and using it. Train operators to understand what alerts mean and how to act on them.

Key tasks:

- Review alerts regularly.

- Update the model when data or process changes.

- Record model decisions and results for audit purposes.

Success signs:

- Fewer manual inspections.

- Faster CAPA closures.

- Higher first-pass yield.

Common Problems and How to avoid them

- Unclear goals: Always connect AI work to clear business results.

- Bad data: Clean and verify your data before modeling.

- Too complex models: Start with simple, explainable models.

- No operator training: Involve your team early to build trust.

- Ignoring compliance: Keep clear records of model decisions for audits.

Case Study: Ramco Fasteners

Company: Ramco Fasteners, a mid-sized manufacturer making hex bolts and special fasteners.

Problem: High rejection rates and long CAPA cycles. Main causes were machine drift and poor data linkage.

Goal: Reduce rejects by 40% in 6 months and shorten CAPA closure time.

Steps taken:

- Collected machine sensor data (speed, temperature) and inspection results.

- Built two models: one for detecting machine anomalies and another to predict product failure.

- Used simple models (autoencoder and decision tree) with expert review.

- Connected alerts to their QMS for automatic ticket creation.

- Set retraining every two months and tracked all changes.

Results:

- 46% fewer rejects (target achieved).

- CAPA closure time reduced from 15 days to 7 days.

- Scrap cost saved around INR 10 Lacs in six months.

- Operators trusted the system and manual checks reduced by 30%.

Lessons learned:

- Data alignment was the biggest early challenge.

- Simple models worked better initially.

- Keeping humans in the loop helped build confidence.

Key Takeaways

- Start small with clear goals and good data.

- Use simple models first; add complexity later.

- Involve your people early and show quick wins.

- Monitor and update your models regularly.

- Keep proper records for audits and learning.

Conclusion:

Implementing AI in QMS is not just about technology—it’s about creating smarter, faster, and more reliable quality systems. By starting small, focusing on good data, and involving people early, companies can see quick wins and long-term benefits. As shown in the case study, even simple AI models can reduce defects, speed up CAPA closure, and enhance decision-making. With a clear roadmap and continuous learning, AI can transform QMS into a predictive, proactive system that drives true operational excellence.