A Control Plan is one of the most important documents in manufacturing and quality management. It ensures consistent production, reduces variation, prevents defects, and helps maintain process stability over time. Whether you work in automotive, engineering, machining, fabrication, plastics, or process industries, a well-designed Control Plan is essential for delivering quality products with repeatable results.

This article explains the purpose of a Control Plan, key elements, types, examples, benefits, best practices, common mistakes, and a ready-to-use template you can apply directly in your factory or quality system.

- What Is a Control Plan?

- Why a Control Plan Is Important

- Inputs Required to Create a Control Plan

- Types of Control Plans

- Key Elements of a Control Plan

- Sample Control Plan Template

- How to Develop a Control Plan Step-By-Step

- Relation Between Control Plan and PFMEA

- Control Plan vs SOP vs Work Instruction

- Benefits of Implementing a Strong Control Plan

- Best Practices for Maintaining an Effective Control Plan

- Common Mistakes in Control Plans

- Example of How a Control Plan Prevents Defects

- Control Plan in IATF 16949 and PPAP

- IATF 16949 Control Plan Requirements

- Summary

What Is a Control Plan?

A Control Plan is a documented description of the methods, systems, and controls required to ensure that a manufacturing process consistently produces products that meet customer requirements. It outlines what needs to be controlled, how it will be monitored, how frequently checks will be done, who is responsible, and what actions must be taken if something goes wrong.

A Control Plan becomes the backbone of day-to-day quality assurance. Operators, supervisors, quality inspectors, and engineers use it to maintain process consistency and prevent defects before they reach customers.

A simple definition:

A Control Plan describes the process controls, inspection methods, reaction plans, measurement frequencies, and responsibilities required to ensure quality throughout the product’s lifecycle.

Why a Control Plan Is Important

A well-structured Control Plan offers several key benefits:

• Ensures process consistency and reduces variation

• Helps prevent defects and maintain product quality

• Defines clear responsibilities for each process step

• Provides inspection methods and measurement techniques

• Ensures operators follow the correct process conditions

• Supports compliance with ISO 9001, IATF 16949, and customer-specific requirements

• Helps auditors verify that critical characteristics are controlled

• Reduces rework, scrap, and customer complaints

• Ensures production stability over time

• Works as a training document for new operators and inspectors

From a manufacturing perspective, a Control Plan is a preventive tool that catches issues before they become bigger problems.

Inputs Required to Create a Control Plan

A Control Plan is not created in isolation. It is built using important quality planning tools and documents such as:

• Process Flow Diagram

• PFMEA (Process Failure Mode and Effects Analysis)

• DFMEA (if applicable)

• Special Characteristics List (critical, major, minor)

• Product Drawing and Specifications

• SOP / Work Instructions

• Customer Requirements

• Past defect data

• Machine capability data

• Inspection and test methods

Linking the Control Plan with these inputs ensures that all potential failures, controls, and reactions are based on risk and real data.

Types of Control Plans

In many industries, especially automotive and engineering, three levels of Control Plans are used:

- Prototype Control Plan

Used during early development when the product is in the prototype stage. Controls are flexible and may change rapidly. - Pre-Launch Control Plan

Used before mass production. Inspection frequency is higher because the process is still stabilising. This is required for PPAP submissions. - Production Control Plan

Used for regular mass production. Controls are stable, and the plan focuses on maintaining long-term process capability.

Understanding these stages helps manufacturers apply the right controls at the right time.

Key Elements of a Control Plan

A strong Control Plan includes the following elements:

• Process Step or Operation Number

• Machine, Equipment, or Tooling Used

• Process Description

• Product or Process Characteristics (CTQ – Critical to Quality)

• Specification / Tolerance

• Measurement Method or Inspection Equipment

• Sample Size or Inspection Frequency

• Control Method (how you maintain the parameter)

• Reaction Plan (what to do if out-of-spec condition occurs)

• Responsibility (operator, quality, supervisor)

• Reference Documents (SOP, Work Instructions, Drawing No.)

• Revision Number, Date, and Approval

These elements ensure that the Control Plan is complete, practical, and actionable.

Sample Control Plan Template

Process Step: 10

Operation: Drilling

Machine: Radial Drill

Characteristic: Hole Diameter (Ø)

Specification: 12.0 ± 0.05 mm

Measurement Method: Vernier Calliper

Frequency: 1 piece every hour

Control Method: Tool setting and periodic calibration

Reaction Plan: Stop the machine, segregate the last 1 hour of production, do a tool change or reset

Responsible Person: Operator / Quality Inspector

Reference: SOP-DRL-01

Revision: 02

This sample shows how a Control Plan clearly defines what needs to be controlled and how.

How to Develop a Control Plan Step-By-Step

Step 1: Review PFMEA and Process Flow Diagram

Identify key failure modes and high-risk process steps. These form the basis of the control strategy.

Step 2: Identify Special Characteristics

Mark CTQ, CPK-critical, safety, regulatory, or customer special characteristics.

Step 3: Determine Control Methods

Define how critical parameters will be controlled, e.g. fixture settings, torque values, temperature limits, speed, pressure, tooling, etc.

Step 4: Choose Measurement Methods

Select appropriate gauges, instruments, test equipment, or visual inspection methods.

Step 5: Decide Inspection Frequency

Higher frequency for high-risk processes or new products; lower for stable processes.

Step 6: Develop a Reaction Plan

Define exactly what must happen if any characteristic is out of specification. This prevents defective products from moving forward.

Step 7: Assign Responsibilities

Clarify who performs the inspection, measurement, and actions.

Step 8: Approve and Release the Control Plan

Ensure process engineering, quality, and production heads approve the document.

Step 9: Train Operators and Inspectors

Share the plan with the team so controls are implemented properly.

Step 10: Review and Update Regularly

A Control Plan must be updated when the process changes, tools are replaced, designs are revised, defects increase, or the PFMEA is updated.

Relation Between Control Plan and PFMEA

Control Plans and PFMEAs go hand-in-hand.

PFMEA identifies risks; the Control Plan defines controls to mitigate those risks.

Without PFMEA, the Control Plan becomes a basic inspection sheet.

Without a Control Plan, PFMEA actions remain theoretical and are not implemented on the shop floor.

Control Plan = Execution tool of PFMEA

PFMEA = Risk identification tool behind the Control Plan

Together, they strengthen your quality system dramatically.

Control Plan vs SOP vs Work Instruction

Control Plan: Defines what to check, control, measure, frequency, and reaction plan.

SOP / WI: Explains how to operate step-by-step.

Inspection Sheet: Records actual measurement results.

A Control Plan is not a replacement for SOPs. Instead, it provides the foundation for creating effective SOPs and inspection sheets.

Benefits of Implementing a Strong Control Plan

• Ensures defect-free production

• Improves process capability

• Reduces scrap and rework

• Ensures consistent and repeatable output

• Supports IATF 16949 and PPAP submissions

• Helps retain knowledge even if manpower changes

• Provides evidence to auditors that processes are controlled

• Reduces customer complaints and warranty issues

• Enhances production discipline

• Enables faster troubleshooting

A strong Control Plan increases reliability and strengthens customer confidence.

Best Practices for Maintaining an Effective Control Plan

• Keep the Control Plan updated after any change in drawing, tooling, or process.

• Use simple, clear language so operators understand it.

• Ensure inspection tools are calibrated and referenced.

• Include reaction plans that are practical and easy to follow.

• Involve production, quality, and engineering teams in preparation.

• Review PFMEA at least once a year and update the Control Plan accordingly.

• Use color coding (optional) for critical characteristics.

• Link each Control Plan line item to actual shop floor practice.

• Avoid too many controls; focus on critical and high-risk areas.

Common Mistakes in Control Plans

• Outdated revision after process changes

• Missing or unclear reaction plan

• Too many characteristics listed, making the plan impractical

• Copy-paste templates without real process understanding

• Missing measurement frequency or using inconsistent frequencies

• No linkage to PFMEA or Process Flow

• Using inspection only, without preventive controls

• Operators not trained on the actual plan

• Not reviewing the plan during internal audits

These mistakes reduce the effectiveness of the Control Plan and can lead to audit findings or customer issues.

Example of How a Control Plan Prevents Defects

Imagine a CNC machining process where a critical bore must be 25 ± 0.02 mm. Without a Control Plan, the operator may check randomly or inconsistently. Variations go unnoticed and defects reach the customer.

With a Control Plan:

• Frequency is defined (e.g., 1 piece every 30 minutes)

• Method is defined (e.g., bore gauge)

• Reaction plan is ready (e.g., stop machine, segregate parts, check last 2 hours stock)

This ensures defects are caught early, quality is stabilised, and customer rejections are prevented.

Control Plan in IATF 16949 and PPAP

Automotive suppliers must maintain a robust Control Plan to meet IATF 16949 and customer requirements. A Control Plan is a mandatory PPAP document used to demonstrate production readiness and process control.

Auditors often check:

• Is the Control Plan aligned with PFMEA?

• Are special characteristics controlled?

• Is frequency suitable for the process risk level?

• Is the plan updated after engineering changes?

• Do operators follow the plan on the shop floor?

• Are reaction plans implemented correctly?

A strong Control Plan supports compliance and ensures zero-defect manufacturing.

IATF 16949 Control Plan Requirements

8.5.1.1 Control Plan

The organisation shall develop control plans at the system, subsystem, component and material level for the relevant manufacturing site and all products supplied, including those for processes producing bulk material as well as parts. Family control plans are acceptable for bulk material and similar parts using a common manufacturing process.

The organisation shall have a control plan for pre-launch and production that shows linkage and incorporates information from the design risk analysis (if provided by the customer), process flow diagram and manufacturing process risk analysis outputs such as FMEA.

The organisation shall, if required by the customer, provide measurement and conformity data collected during the execution of either the pre-launch or production control plans. The organisation shall include in the control plan:

- controls used for the manufacturing process control, including verification of job set-ups

- First off/last off part validation as applicable

- Methods for monitoring of control exercised over special characteristics defined by both the customer and the organisation

- The customer required information if any

- Specified reaction plan when a non-conforming product is detected, the process becomes statistically unstable or not statistically capable.

The organisation shall review control plans and update as required, for any of the following:

- The organisation determines that it has shipped non-conforming products to the customer

- When any change occurs affecting the product, the manufacturing process, measurement, logistics, supply sources, production volume changes or risk analysis (FMEA)

- After a customer complaint and the implementation of the associated corrective action when applicable

- At a set frequency based on a risk analysis

If required by the customer, the organisation shall obtain customer approval after review or revision of the control plan.

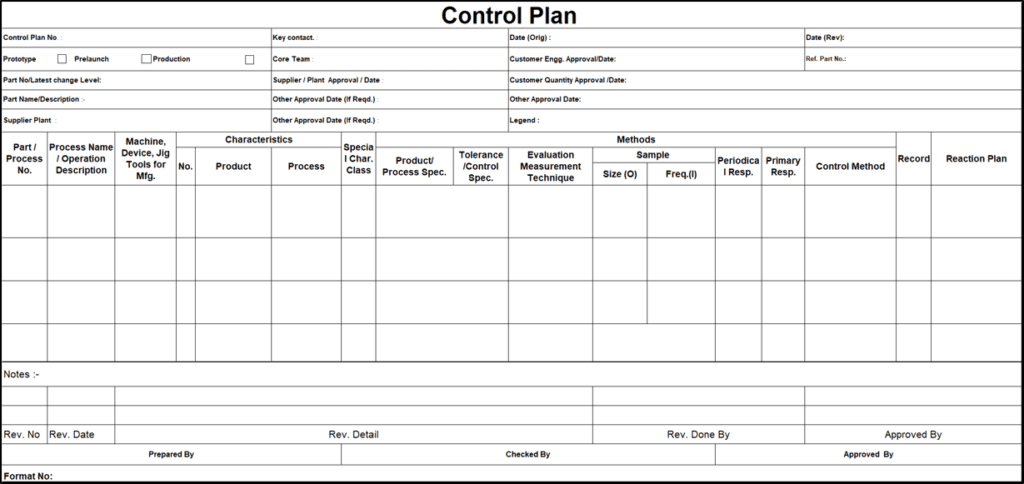

Control Plan Format in Excel:

Control Plan Header:

- Control plan number

- Effective date or Revision date

- Customer description

- Organization description

- Part description

- Part number/Latest change level

- Engineering change level

- Phase ( Prototype / pre-launch / Production )

- Key Contact person

- Process step

- Process description

Elements of the Control Plan:

- Control Plan Phase: Mark the type of control plan in the box, whether it is prototype, prelaunch or production.

- Control Plan Number: Provide the document number of the control plan as per the document number system.

- Part Number/Latest Change: Write the part number as mentioned in the drawing. Internal part numbers can be written here if any.

- Part Name/Description: Write the name or description of the part as mentioned in the drawing. But if the control plan is of the family of parts, then mention the family model name here.

- Supplier/Plant: Write the name of the company or plant where the production run

- Organisation Code: Mention the organisation code as provided by the customer

- Key Contact/Phone: Write the Name and contact number of the responsible person for the process

- Core Team: Write the name of the cross-functional team that was involved in preparing the control plan

- Supplier/Plant Approval Date: Write the document approval date by the customer

- Other Approval/Date: Write any additional approval information and date if required

- Date Original: Write the date when the control plan was initially developed

- Date/Rev: Write the latest revision date of the control plan

- Customer Engineering Approval/Date: Write the customer engineering approval date if required

- Customer Quality Approval/Date: Mention customer quality approval if required

- Other Approval/Date: Write any additional approval information and date if required

- Part/Process Number: Mention the process step as per the process flow diagram

- Process Name/Operation Description: Write the process name as mentioned in the process flow diagram

- Machine/Device/Jigs/Tool for Manufacturing: Write the equipment, machines, tools, fixtures, jigs etc required for the particular operation

- Product characteristics: Product characteristics are physical features of the part or assembly as mentioned in the part drawing.

- Process characteristics: Process characteristics are those features that are related to the process. For example, for a Mig welding process

- Special Characteristics: Write the defined symbol for the special characteristics in this column in front of the product and process characteristics as applicable.

- Product/Process Specification/Tolerance: Write here the product and process specifications with tolerance as per the drawing and process.

- Evaluation/Measurement technique: Write the relevant measuring instrument, gauge or testing equipment for the product and process. For example, appearance is checked visually and a dimension (diameter) is checked by a micrometer.

- Sample Size: Write the number of parts to be checked during the setup and in-process

- Inspection Frequency: Write the frequency after which sampling will be done. It may be 1 hour, 2 hours or 4 hours as per the requirement per shift. Also it can be at the start, mid and end.

- Responsibility: Primary responsibility for part and process inspection is mentioned in this column.

- Control method(Prevention/Detection): Write the record name that is used to control that parameter. for example, Setup Approval report, in-process inspection report, Final inspection report, error proofing, daily machine check sheet, tool history card etc

- Record: In this column, mention whether the record is to be kept or not.

- Reaction Plan: Write the applicable containment action and corrective action in the reaction plan column.

The control plan should be reviewed and updated periodically. The control plan is a living document.

Summary

A Control Plan is a powerful tool that ensures consistent product quality, reduces process variation, and provides clarity for operators and quality teams. It connects directly with PFMEA, process flow, and SOPs, ensuring that preventive controls and reaction plans are properly defined and implemented on the shop floor. By maintaining a robust, updated, and practical Control Plan, manufacturers can reduce defects, improve reliability, meet customer requirements, and strengthen their quality system.

If maintained correctly, the Control Plan becomes more than a document—it becomes the heartbeat of your production quality system.

Reference: IATF 16949 Standard

You may like to read about:

Hi, you have shared a good information. My query is whether this can be followed by sales and service industry too?

Thank you.

Thanks for your query.These control plans are for the manufacturing industry only. But control plan for service industry can be created.

I highly recommend ernestopro.com for anyone looking to implement effective control plans in quality management. Their comprehensive approach and detailed resources on different types of control plans, including IATF 16949 standards, make them an invaluable partner. The clarity in their format examples and input guidelines greatly simplify the process of preparing and understanding control plans. Trust ernestopro.com to enhance your quality control processes with expert support and insightful solutions.

Fabulous, what a blog it is! This weblog provides valuable

facts to us, keep it up.

What’s up Dear, are you really visiting this web page daily, if so then you will without doubt take nice

know-how.

Write more, thats all I have to say. Literally, it seems as though you relied on the video to make your point.

You definitely know what youre talking about, why waste your intelligence on just posting videos to your site when you could be giving us

something enlightening to read?

Hey there! I simply would like to offer you a big thumbs

up for the great information you have here on this post.

I’ll be coming back to your website for more soon.

I do consider all the ideas you’ve offered on your post.

They are really convincing and can certainly work.

Still, the posts are very short for newbies. Could you please lengthen them

a bit from next time? Thanks for the post.

My brother suggested I may like this web site. He was once totally right.

This put up actually made my day. You cann’t consider just how much time I had spent for this info!

Thank you!

Please let me know if you’re looking for a article author for your blog.

You have some really great articles and I think I would be a good asset.

Hiya, I’m really glad I’ve found this information. Today bloggers publish just about gossips and internet and this is really irritating. A good web site with interesting content, this is what I need. Thanks for keeping this website, I will be visiting it. Do you do newsletters? Can’t find it.

I gotta favorite this site it seems very beneficial.

I am actually glad to read this web site posts which carries lots of valuable facts, thanks for providing such

data.