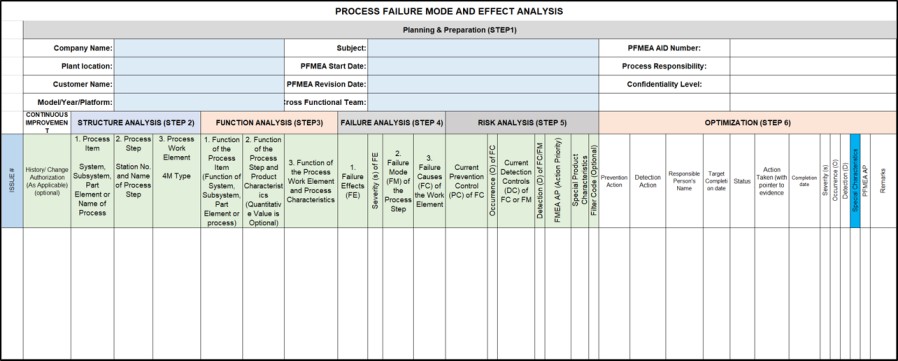

There are 6 steps in the FMEA process as per VDA & AIAG. These 6 steps provide a systematic approach to failure mode and effect analysis.

- Scope Definition and Project Planning

- Structure Analysis

- Function Analysis

- Failure Analysis

- Risk Analysis

- Optimization

1. Scope Definition & Project Planning :

The purpose of the process scope definition is to decide what product/process to include/exclude for review in the PFMEA project. Below are the main objectives for defining the scope:

- Project identification

- Project Plan

- Define the boundary of the analysis

- Identify the lesson learning sheet.

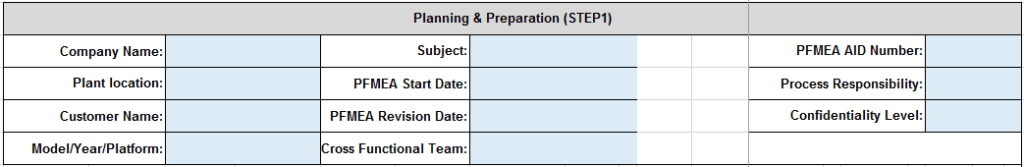

During the scope definition PFMEA header should be filled as below:

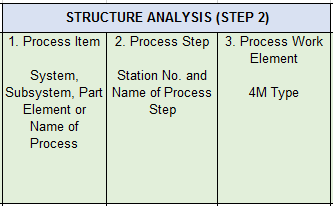

2. Structure Analysis:

The purpose of process structure analysis is to identify and categorize the production system into

- Process Item

- Process Step

- Process Work Element.

The main objective of Process structure analysis:

- System structure for a product or element of a process.

- Visualization of the scope of the analysis

- Identification of the process steps

- Basis for the function analysis steps

A Process flow diagram or Structure tree helps to define the process and provide the basis for structure analysis.

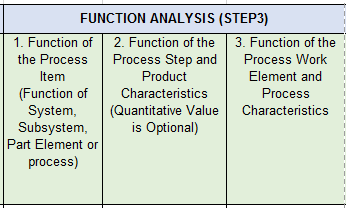

3. Function Analysis :

The purpose of the process function analysis is to ensure that the intended functions of the product/process are defined adequately.

The main objective of the function analysis :

- Check the functionality of the process

- Visualization of the process function using a process flow diagram.

- Association of characteristics to function

- Basis for failure analysis

A function describes what the process item or process step is intended to do.

A requirement is related to the performance of the function and can be measured. Requirement falls into 2 categories :

- Product characteristics

- Process characteristics.

A product’s characteristics like geometry, material specification and surface finish etc. A process characteristic is shown on manufacturing operation standards or work instructions. A process characteristic like pressure, temperature, current, voltage etc.

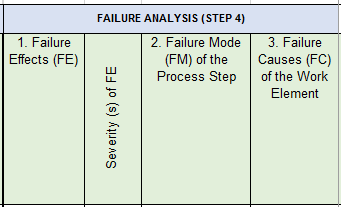

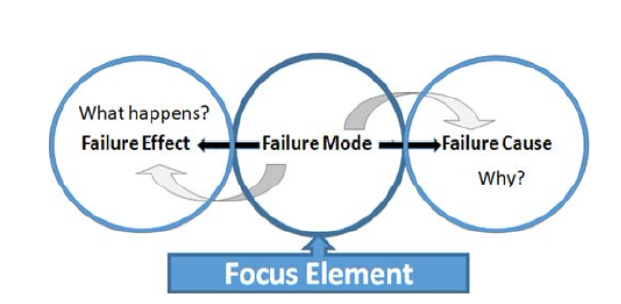

4. Failure Analysis :

The purpose of the process failure analysis is to identify failure causes, modes and effects.

The main objective of the Process failure analysis :

- Establishment of the failure for each function of the process item

- Identification of the possible failure to process an element or step.

- Visualization of the failure relationship

- The effect may be shared by the customer with their supplier.

Failure of a process step is non-conformity to product or process characteristics. For a specific failure there are three categories:

- Failure effect

- Failure mode

- Failure cause

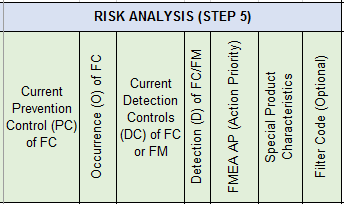

5. Risk Analysis :

The purpose of the risk analysis is to estimate risk by evaluating severity, occurrence and detection and prioritize the need for action.

The main objective of the risk analysis :

- Identify prevention control

- Identify detection control

- Rating of severity, occurrence and detection

- Communication between the customer and the supplier on the severity.

There are two different control groups :

- Current prevention control

- Current detection control

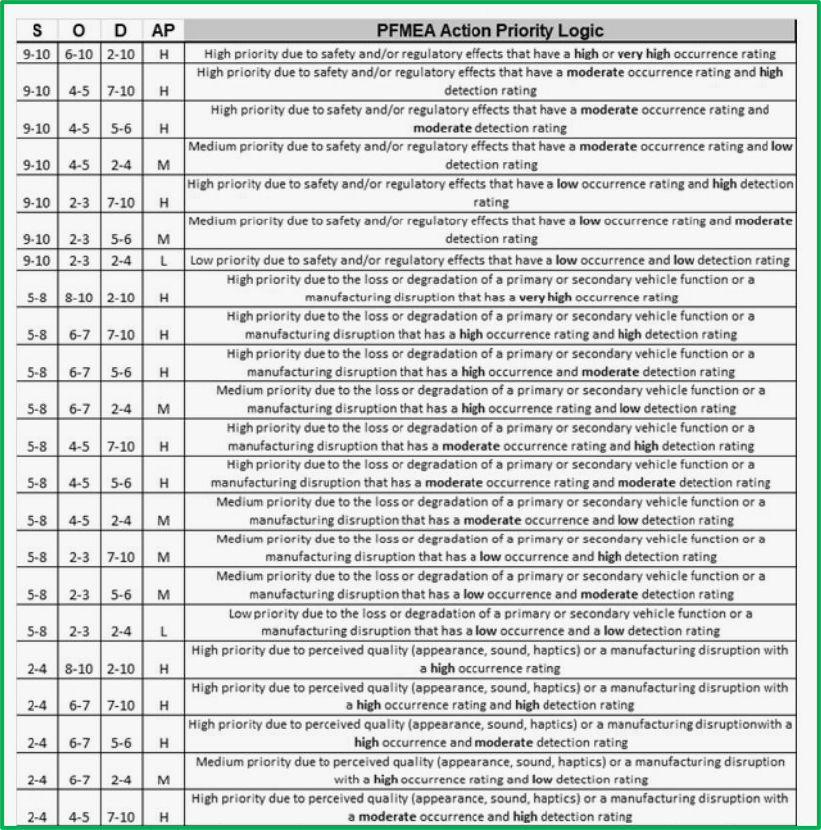

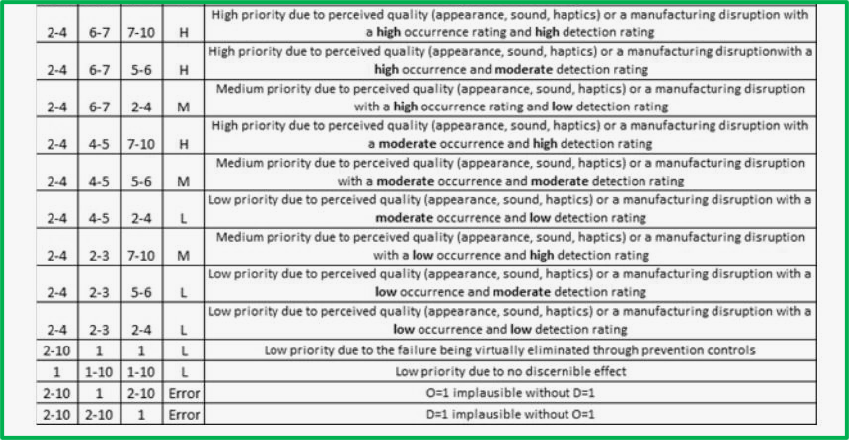

Action Priority (AP) :

In this new FMEA Action Priority (AP) replaced the RPN. The AP table provides the logic detail for the FMEA team for all 1000 combinations of S, O and D. It includes the logic-based description of each action priority level. There are 3 types of action priority in the AP table as below :

Priority High (H) :

The team must take or identify action to improve prevention or detection control. Or justify that the current control is OK.

Priority Medium (M) :

The team should take or identify action to improve prevention or detection control, or justify that the current control is OK.

Priority Low (L) :

There is a low priority for action. It means no need to take any action.

PFMEA Action Priority Table:

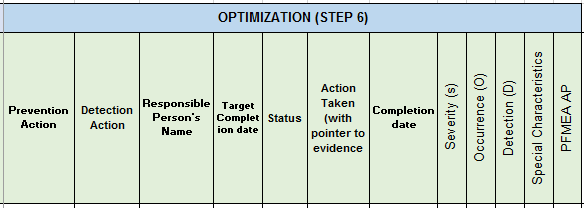

6. Optimization :

The purpose of the process optimization step is to determine actions to mitigate risk and assess the effectiveness of these actions.

The main objective of the process optimization :

- Identification of the action necessary to reduce risk

- Assignment of the action and target completion time for action implementation

- Implementation and documentation of the action taken

- Confirmation of the effectiveness of the action taken

- Continuous improvement of the process

FMEA result documentation :

The scope and result of an FMEA should be summarized in a report. The report can be used for communication purposes within the company or with customers.

AIAG VDA FMEA FORMAT:

AIAG VDA FMEA Example:

Reference: AIAG VDA FMEA

I think other web-site proprietors should take this web site as an model, very clean and fantastic user friendly style and design, as well as the content. You are an expert in this topic!