What is FMEA?

An FMEA can be described as a schematic group of activities to :

- Identify the potential failure modes for a product or process.

- Assess the risk (effects) associated with those failures.

- Rank failure in terms of importance.

- Identify and carry out corrective actions to address the most serious concerns.

In FMEA each failure is considered as an independent occurrence with no relation to other failures in the system.

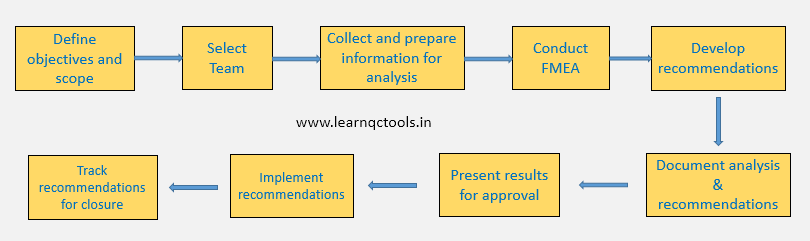

Basic steps for conducting an FMEA:

- The objectives and scope of the FMEA are defined by the team leader.

- A cross-functional analysis team of 4 to 7 people is assembled. The team brainstormed for each activity.

- The team then gathers and prepares information for analysis. The team team first understands fully what the product/process must do to satisfy the customer. It also reviews relevant information such as similar FMEA done in the past and feedback already in the market.

- The team then conducts the FMEA. Do this activity as per the FMEA Procedure.

- The next step is to develop recommendations. This includes prioritizing and assigning corrective actions.

- Then analysis and recommendations are documented.

- The team then presents for approval.

- The process owner implements the recommendations.

- Finally the implementation of the recommendation is tracked.

The early and consistent use of FMEA in the design process allows the engineer to design out failures and produce reliable, safe and customer satisfied products.

FMEA identify potential failure modes for a product or process, assesses the risk associated with those failure modes and carries out corrective actions to address the most serious concerns.

Potential failure effects are what the next user of products or process would experience.

Severity (S) is the seriousness of the effect of the failure.

Occurence (O) is the likelihood that a specific cause will occur during the design life of the product/process.

Detection (D) is the probabilty that the current control will detect the potential cause or subsequent failure.

You may like to know about AIAG VDA FMEA

PFMEA in an Automotive Industry and Severity, Occurence and Detection ranking charts.

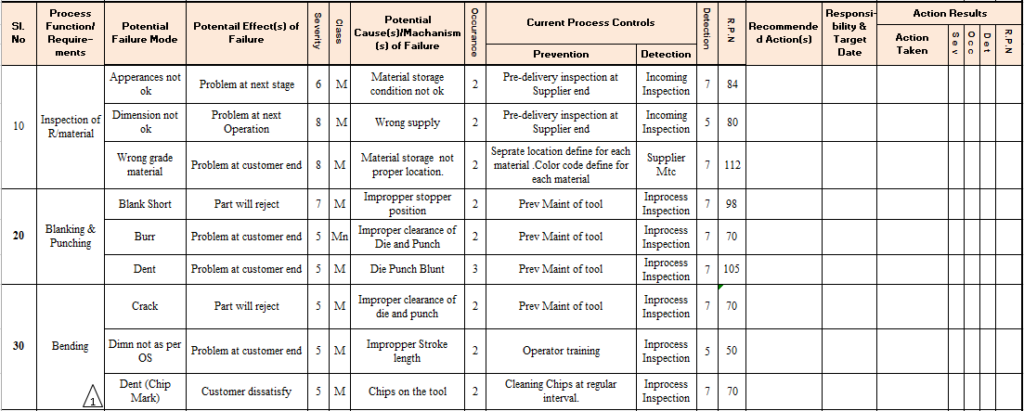

Examples of PFMEA in manufacturing:

Stamping Process PFMEA:

Machining process fmea example: