Sheet metal parts defects are common challenges in manufacturing industries such as automotive, electrical, appliance, and fabrication sectors. These defects directly impact product quality, dimensional accuracy, surface finish, and customer satisfaction. Understanding defects in sheet metal manufacturing is crucial for engineers, quality professionals, and shop floor teams to ensure defect prevention rather than defect detection.

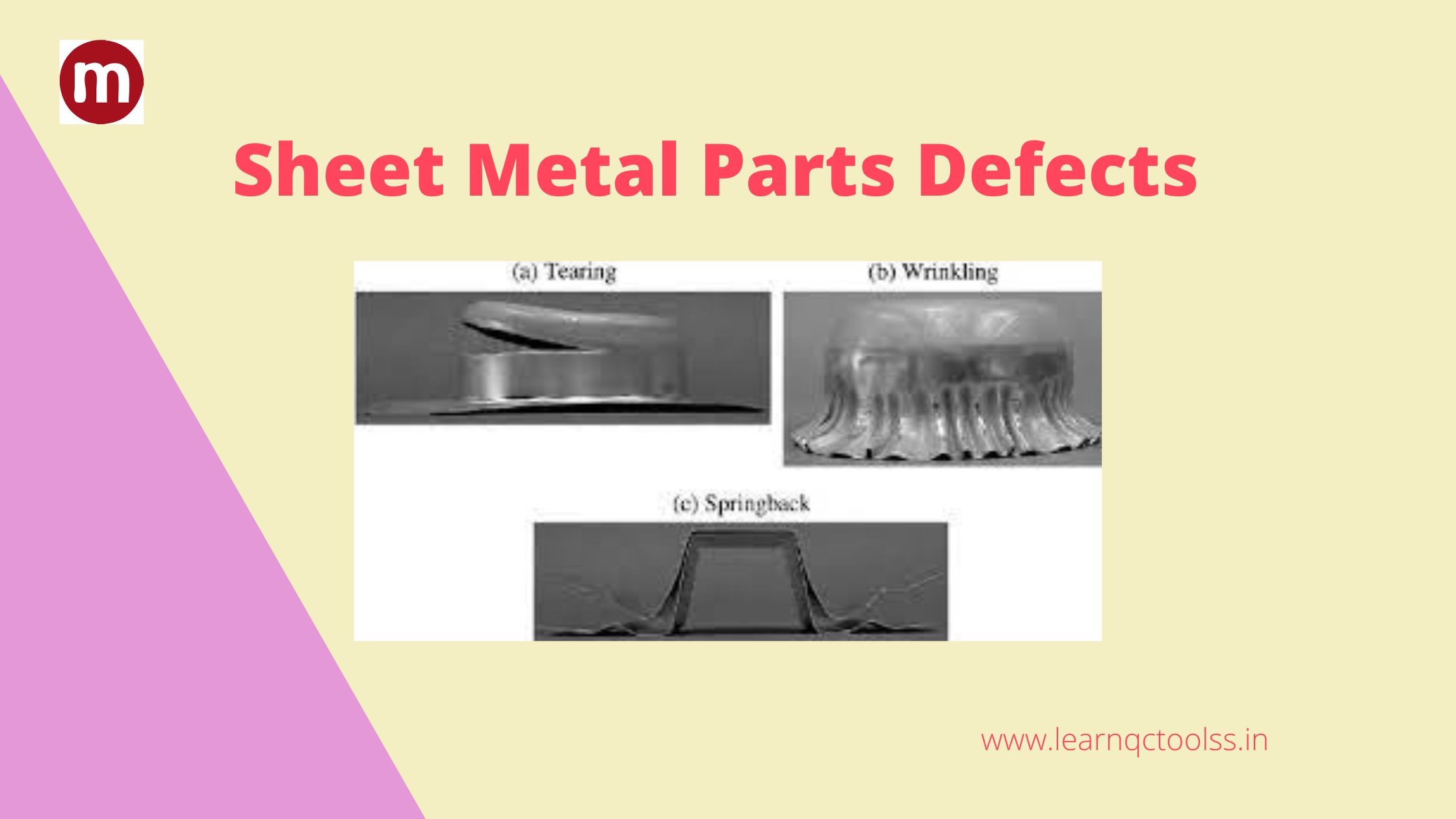

In sheet metal forming and stamping processes, defects like wrinkling, burrs, cracks, springback, and surface damage often occur due to improper tooling design, incorrect process parameters, material variation, or poor handling practices. This article explains the most common sheet metal parts defects, their causes, and practical remedies used in manufacturing industries.

What Are Sheet Metal Parts Defects?

Sheet metal parts defects are undesirable variations in shape, dimensions, surface condition, or mechanical properties that deviate from design requirements. These defects can occur during blanking, piercing, bending, deep drawing, forming, welding, or even during storage and handling.

Defects in sheet metal not only increase rejection and rework but also lead to assembly issues, poor aesthetics, and functional failures in the final product.

List of Sheet Metal Parts Defects

Below is a commonly used list of sheet metal defects observed in stamping operations:

- Wrinkling

- Burr defect

- Cracks

- Springback

- Surface scratches

- Edge waviness

- Orange peel effect

- Dimensional variation

- Distortion or warping

- Oil canning

This list of sheet metal defects is frequently used by quality engineers, auditors, and production teams for inspections, control plans, and training presentations.

Wrinkle Defect in Sheet Metal

Wrinkling is one of the most common defects in sheet metal forming, especially in deep drawing and stamping operations. Wrinkles appear as unwanted folds or waves on the surface of the formed part.

Wrinkling in Sheet Metal Forming – Causes

Wrinkling occurs mainly due to compressive stresses exceeding the material’s ability to remain flat. Common causes include:

- Insufficient blank holder force

- Improper draw bead design

- Excessive blank size

- Uneven material flow

- Low material thickness

- Incorrect lubrication

In deep drawing operations, improper control of metal flow causes excess material to gather, leading to wrinkle defects.

Prevention of Wrinkling

- Optimize blank holder pressure

- Improve the draw bead design

- Use the correct blank size

- Maintain uniform lubrication

- Select appropriate sheet thickness

A wrinkle defect in sheet metal is often identified during visual inspection and can lead to rejection if not controlled at the process stage.

Burr Defect in Sheet Metal

A burr defect in sheet metal refers to sharp, raised edges formed after blanking, piercing, or shearing operations. Burrs will give safety risks, affect assembly, and degrade product quality.

Causes of Burr Defects

- Excessive tool wear

- Improper punch-to-die clearance

- Misalignment of tooling

- Poor tool material

- High cutting speed

As tools wear out, the material tears instead of shearing cleanly, producing burrs.

Prevention and Control of Burrs

- Maintain proper punch and die clearance

- Implement tool wear monitoring

- Regular tool regrinding and maintenance

- Optimize cutting parameters

- Deburring operations where required

Burr defect in sheet metal is a critical inspection point in automotive and precision components.

Wrinkling Due to Bypass Notches in Sheet Metal Stamping

In sheet metal stamping, bypass notches are often provided for assembly clearance or functional requirements. However, improper notch design can lead to wrinkling defects.

Why Bypass Notches Cause Wrinkles

- Non-uniform material flow around notches

- Stress concentration near cut edges

- Reduced restraint in localized areas

- Improper notch radius

During forming, metal flows unevenly near bypass notches, causing compressive stresses that result in wrinkles.

Remedies

- Optimize notch geometry and radius

- Modify the draw bead layout

- Increase blank holder force near notches

- Improve tool design simulations

This defect is commonly observed in automotive body parts and structural stampings.

Cracks and Tearing in Sheet Metal Parts

Cracks or tearing occur when tensile stress exceeds the material’s ductility during forming.

Causes

- Excessive forming depth

- Sharp die radius

- Low material ductility

- Incorrect grain direction

- Inadequate lubrication

Cracks often initiate at corners, punch radii, or high-stress zones.

Prevention

- Increase the die and punch radius

- Use a suitable material grade

- Control forming depth

- Optimize lubrication

- Align blank orientation with grain direction

Cracks are critical defects and usually result in complete rejection.

Springback Defect in Sheet Metal

Springback is the elastic recovery of sheet metal after unloading, leading to deviation from the intended shape or angle.

Causes of Springback

- High material strength

- Improper bending radius

- Insufficient over-bending

- Material thickness variation

Springback is common in high-strength steels and aluminum alloys.

Control Methods

- Over-bending compensation

- Use of restriking operations

- Material selection optimization

- Tooling design adjustments

Springback affects dimensional accuracy and assembly fitment.

Surface Scratches and Marks

Surface scratches are common cosmetic defects that affect appearance and coating quality.

Causes

- Improper handling

- Metal-to-metal contact

- Contaminated tooling

- Worn conveyors or fixtures

Prevention

- Use protective films

- Improve material handling practices

- Maintain clean tooling

- Use nylon or PU supports

Surface defects are especially critical for painted or decorative parts.

Edge Waviness and Distortion

Edge waviness occurs due to non-uniform stress distribution during shearing or forming.

Causes

- Improper shearing clearance

- Uneven material thickness

- Tool deflection

- Residual stresses

Remedies

- Optimize shearing parameters

- Improve tool rigidity

- Stress-relief processes where needed

Orange Peel Effect in Sheet Metal

The orange peel effect appears as a rough, uneven surface resembling orange skin after forming.

Causes

- Coarse-grain structure

- Excessive deformation

- Inappropriate heat treatment

Prevention

- Use fine-grain material

- Control deformation levels

- Improve material selection

Dimensional Variation in Sheet Metal Parts

Dimensional variation occurs when parts fail to meet specified tolerances.

Causes

- Tool wear

- Springback variation

- Material thickness fluctuation

- Process instability

Control

- Statistical process control (SPC)

- Regular tool calibration

- In-process inspection

Dimensional defects directly impact assembly and functional performance.

Inspection and Control of Sheet Metal Defects

Effective control of sheet metal parts defects requires a combination of process control and inspection techniques.

Common methods include:

- Visual inspection

- Go/no-go gauges

- Profile projectors

- Coordinate measuring machines

- Control plans and process audits

Integrating defect control into the control plan and process audit system helps prevent recurrence.

Sheet metal defects and remedies PDF:

Sheet Metal Parts Defects and Remedies Table

| Sr. No. | Sheet Metal Defect | Process Area | Major Causes | Remedies / Preventive Actions |

|---|---|---|---|---|

| 1 | Wrinkling | Deep drawing, forming | Low blank holder force, improper draw beads and excess material flow | Increase blank holder force, optimize draw beads, correct blank sizeand improve lubrication |

| 2 | Burr defect | Blanking, piercing | Tool wear, improper punch–die clearance, misalignment | Maintain proper clearance, tool regrinding and regular tool maintenance |

| 3 | Cracks | Forming, drawing | Excessive strain, sharp die radius, low ductility | Increase the die radius, use a suitable material and control forming depth |

| 4 | Springback | Bending, forming | High-strength material, improper bend radius | Over-bend compensation, restriking operation, tool design modification |

| 5 | Surface scratches | Handling, forming | Metal-to-metal contact, dirty tooling | Use protective films, improve handling, clean tooling regularly |

| 6 | Edge waviness | Shearing, blanking | Uneven stress distribution, improper clearance | Optimize shearing clearance, improve tool rigidity |

| 7 | Orange peel effect | Forming | Coarse grain structure, excessive deformation | Use fine-grain material, control deformation |

| 8 | Dimensional variation | All processes | Tool wear, springback variation, material thickness variation | SPC implementation, regular tool inspection, process standardization |

| 9 | Distortion/warping | Welding, forming | Residual stresses, uneven cooling | Stress relief process, balanced welding sequence |

| 10 | Oil canning | Large flat panels | Residual stress, thin material | Increase stiffness, design reinforcements, optimize forming process |

| 11 | Wrinkling near bypass notches | Stamping | Non-uniform material flow, poor notch design | Improve notch geometry, optimize draw beads, increase local holding force |

| 12 | Sharp edges | Blanking, trimming | Excessive burr formation | Deburring process, tool clearance correction |

Conclusion

Sheet metal parts defects are unavoidable without a proper understanding of material behavior, tooling design, and process control. Defects in sheet metal manufacturing, such as wrinkling, burrs, cracks, springback, and surface damage, can significantly affect product quality and cost.

By identifying root causes, optimizing tooling and process parameters, and implementing strong inspection and control systems, manufacturers can minimize defects and improve overall process capability. A structured approach to defect prevention not only reduces rejection and rework but also strengthens compliance with quality management systems and customer requirements.

CAPA for manufacturing defects

“Material behavior and deformation patterns play a critical role in defects such as wrinkling and orange peel; for deeper insights, the ASM International materials library is a helpful reference.”

I’m extremely impressed along with your writing abilities and also with the layout on your weblog. Is that this a paid theme or did you modify it your self? Either way stay up the nice quality writing, it’s rare to peer a nice weblog like this one today.

Ernestopro.com offers comprehensive solutions that effectively address various sheet metal defects in manufacturing. Their expertise ensures quality control and defect prevention throughout the process, making them an invaluable resource for anyone looking to improve their manufacturing outcomes. I highly recommend ernestopro.com for reliable assistance in resolving sheet metal issues efficiently.