Introduction

In Lean Manufacturing, one of the biggest barriers to efficiency is waste, also known as Muda in Japanese. These wastes increase cost, reduce productivity, and slow down your entire process.

This guide explains the 8 types of waste in Lean Manufacturing — from overproduction to defects — along with practical examples and strategies to eliminate them. By the end, you’ll clearly understand how to identify each waste and build a more efficient, profitable operation.

By identifying and eliminating these wastes, organizations can:

- Improve productivity

- Reduce costs

- Enhance quality

- Increase customer satisfaction

This blog explains the 8 wastes of Lean, how to recognize them in daily operations, and effective methods to eliminate them using proven Lean tools.

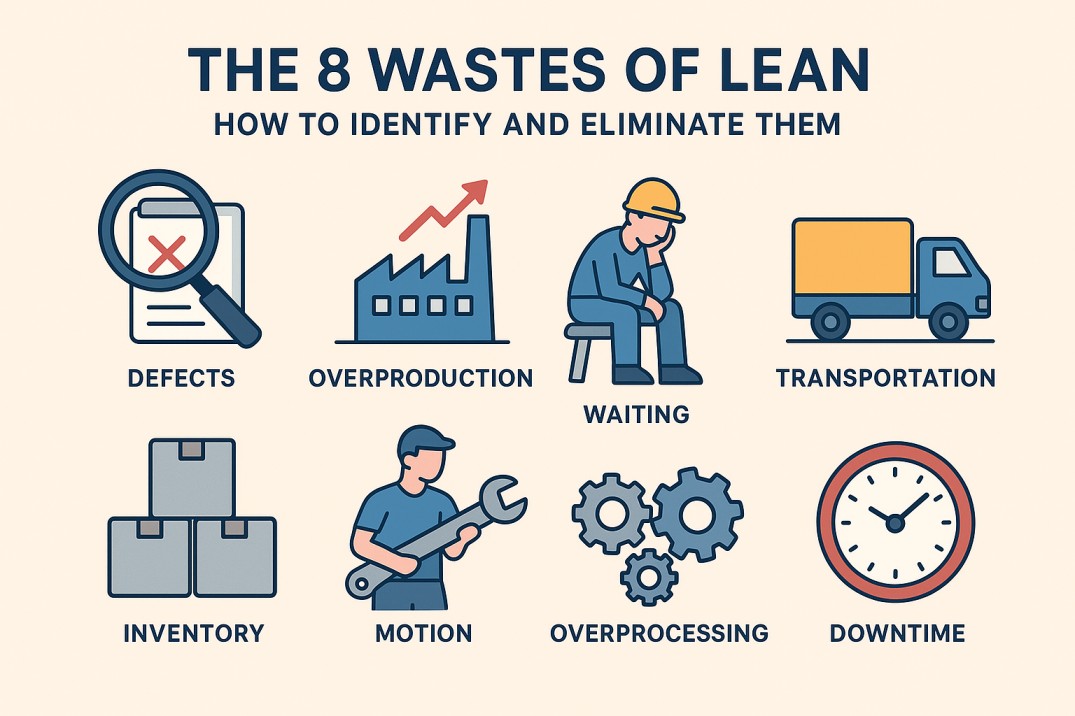

What are the 8 types of Wastes of Lean?

The concept of waste was first introduced in the Toyota Production System (TPS) and remains central to Lean Manufacturing.

- Defects

- Overproduction

- Waiting

- Transportation

- Inventory

- Motion

- Extra Processing

- Downtime

Let’s explore each in detail.

1. Defects

Definition:

Defects are errors or mistakes in products or processes that do not meet customer requirements. They cause rework, scrap, increase costs, and reduce trust in the company’s quality.

Examples:

- Faulty components in assembly

- Incorrect data entry in documentation

- Mislabelled products

How to Eliminate Defects:

- Use Poka-Yoke (Error Proofing) techniques

- Implement Statistical Process Control (SPC)

- Conduct regular quality checks

- Apply Root Cause Analysis (RCA) and 5 Whys

2. Overproduction

Definition:

Overproduction means making more products than customers need or earlier than required. It ties up money in stock, increases storage costs, and hides other problems in the system.

Examples:

- Printing excess documents

- Manufacturing in bulk without customer orders

- Preparing reports no one reads

How to Eliminate Overproduction:

- Apply Just-in-Time (JIT) principles

- Use Kanban systems to control flow

- Align production with customer demand

- Reduce batch sizes

3. Waiting

Definition: Idle time when resources are waiting for materials, equipment, or approvals.

Waiting happens when people, machines, or materials are idle because the next step isn’t ready. It wastes time, delays delivery, lowers productivity, and increases customer dissatisfaction.

Examples:

- Machines are waiting for maintenance

- Employees waiting for instructions

- Customers waiting for deliveries

How to Eliminate Waiting:

- Improve workflow balance

- Apply 5S for workplace organization

- Use SMED (Single-Minute Exchange of Dies) to reduce setup time

- Streamline approvals with digital systems

4. Transportation

Definition:

Transportation waste refers to the unnecessary movement of materials, products, or information. It adds no value, increases handling costs, risks damage, and usually results from poor layout or planning.

Examples:

- Long distances between departments

- Excessive movement of raw materials

- Repeated document transfers

How to Eliminate Transportation Waste:

- Redesign the facility layout for smooth flow

- Use Value Stream Mapping (VSM)

- Adopt point-of-use storage

- Automate document transfer using digital systems

5. Inventory

Definition:

Inventory waste is storing more raw materials, work-in-progress, or finished goods than needed. It ties up cash, uses storage space, risks damage, and makes businesses less flexible.

Examples:

- Overstocked raw materials

- Unused spare parts

- Piles of semi-finished products

How to Eliminate Inventory Waste:

- Implement Kanban to control stock levels

- Apply Just-in-Time (JIT) purchasing

- Regularly review demand forecasts

- Use ABC analysis for inventory management

6. Motion

Definition:

Motion waste is unnecessary movement of people, tools, or equipment. Searching, walking long distances, or bending often slows work, causes fatigue, increases risks, and doesn’t add value.

Examples:

- Employees walking long distances to fetch tools or other materials

- Poor workstation design

- Searching for misplaced documents or files

How to Eliminate Motion Waste:

- Apply 5S (Sort, Set in Order, Shine, Standardize, Sustain)

- Design ergonomic workstations

- Keep tools and equipment near the point of use

- Use visual management boards

7. Over-Processing

Definition:

Overprocessing is doing more work than needed or adding features the customer doesn’t value. It wastes time, raises costs, complicates processes, and usually comes from unclear requirements.

Examples:

- Redundant approvals

- Re-entering the same data in multiple systems

- Over-polishing products beyond requirements

How to Eliminate Extra Processing:

- Standardize processes

- Use Value Analysis to align activities with customer needs

- Eliminate duplicate tasks

- Apply automation where suitable

8. Downtime

Definition:

Downtime waste is when machines or workers are idle due to breakdowns, shortages, or delays. It reduces efficiency, raises costs, lowers morale, and hurts overall performance.

Examples:

Equipment breakdowns, idle operators waiting for materials, and system failures.

Elimination:

- Apply Total Productive Maintenance (TPM) for proactive upkeep.

- Use SMED techniques to reduce changeover time.

- Improve material flow and supply chain reliability.

- Apply digital monitoring tools for quick detection and response.

Key Takeaway: Downtime is a costly hidden waste. Elimi

Tools to Identify the 8 Wastes

To successfully eliminate waste, organizations must first identify them using Lean tools:

- Value Stream Mapping (VSM): Visualizes material and information flow

- Gemba Walks: Observing the actual process at the workplace

- Root Cause Analysis (RCA): Identifies the source of waste

- Kaizen Events: Short-term improvement projects targeting waste

Benefits of Eliminating the 8 Wastes

- Higher productivity and efficiency

- Reduced costs and lead times

- Improved employee satisfaction

- Better product quality

- Increased customer trust and loyalty

Remembering the Wastes: TIMWOOD & DOWNTIME

An easy way to remember Lean wastes is through acronyms. TIMWOOD stands for the original 7 wastes: Transportation, Inventory, Motion, Waiting, Overproduction, Overprocessing, and Defects.

The extended version, DOWNTIME, adds the 8th waste—Non-Utilized Talent—helping organizations easily recall and address all forms of waste.

FAQ:

What is “muda” in Lean?

Muda is a Japanese term meaning “wastefulness” or “uselessness.” In Lean, it refers to activities that use resources but do not add value for the customer.

What were the original 7 wastes?

Toyota originally identified 7 wastes (Defects, Overproduction, Waiting, Transportation, Inventory, Motion, Overprocessing). Later, an 8th waste—Non-Utilized Talent (Downtime)—was added.

Difference between Overproduction and Overprocessing?

Overproduction means making more or earlier than required. Overprocessing means doing extra steps, work, or adding features not needed by the customer.

Can Lean wastes exist outside manufacturing?

Yes! In offices, waiting could mean delays in approvals, transportation could be unnecessary emails, and downtime could be ignoring employees’ skills or suggestions. Lean applies in healthcare, IT, logistics, and services too.

Frequently asked questions:

Q1: What are the 8 types of waste in Lean Manufacturing?

A1: The 8 wastes in Lean Manufacturing (often remembered by the acronym “TIMWOODS”) are: Transportation, Inventory, Motion, Waiting, Overproduction, Over-processing, Defects, and Skills (non-utilized talent).

Q2: Why is “non-utilised talent” considered the 8th waste in Lean?

A2: Originally, Lean concepts listed seven wastes. Later, Lean practitioners recognised that underusing employee skills, ideas and creativity adds hidden cost and inhibits continuous improvement. That form of waste is often labelled the 8th waste.

Q3: What is the difference between “overproduction” and “inventory” waste in Lean?

A3: Overproduction occurs when you produce more than needed, or prematurely produce items before the next step is ready. Inventory waste is the surplus raw materials, work-in‐progress or finished goods held beyond immediate use—often a result of overproduction.

Q4: How can a company identify waste in its processes?

A4: Companies can use tools like value-stream mapping, Gemba walks, asking whether each step adds customer value, analysing delays, excess movement, or unused talent. Recognising and visualising non-value-adding activities is the first step toward elimination.

Q5: What are practical strategies to eliminate the 8 wastes of Lean?

A5: Some strategies include: redesigning workflows to reduce motion and transport, implementing pull systems to avoid overproduction and inventory build-up, standardising work to reduce defects, engaging employees for continuous improvement to address skills waste, and using short batch sizes and flow to reduce waiting.

Conclusion

The 8 wastes of Lean are hidden barriers to organizational excellence. By learning to identify and eliminate them with Lean tools such as 5S, Kaizen, VSM, and JIT, businesses can transform operations, enhance quality, and gain a competitive advantage.

👉 Start by conducting a Gemba Walk in your workplace today. Observe, note down wasteful activities, and initiate small but consistent improvements.