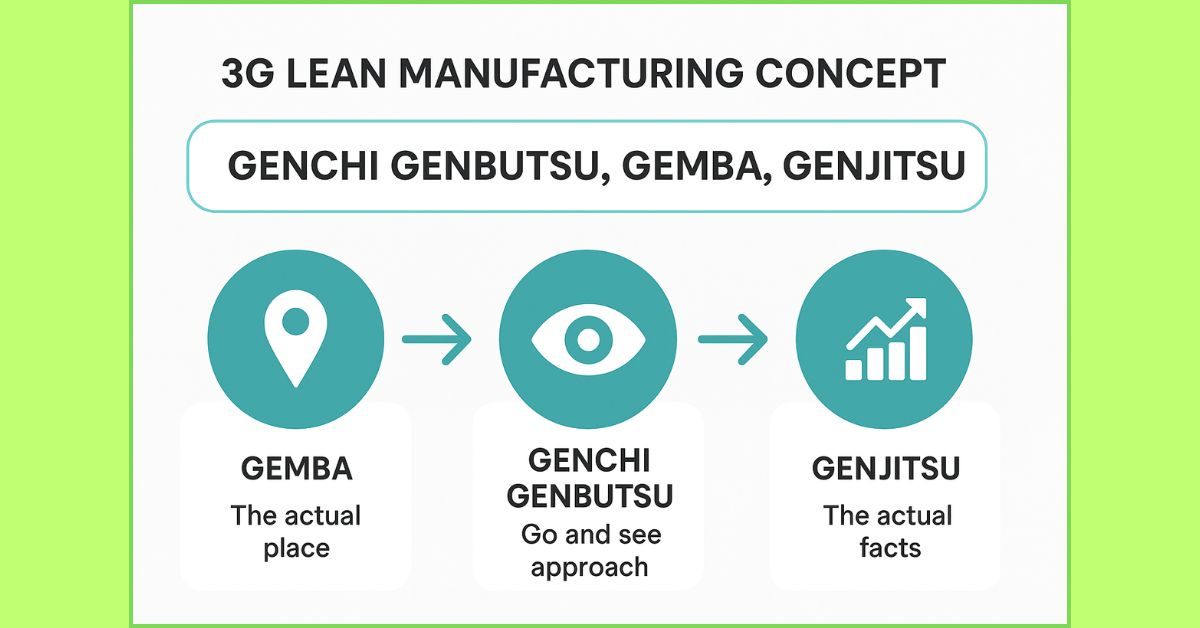

3G Principle in Manufacturing | Japanese 3G Concept Explained

The 3G Principle—Genchi Genbutsu, Gemba, and Genjitsu—is one of the strongest foundations of Japanese manufacturing. It is widely used in the Toyota Production System (TPS), lean manufacturing, and automotive industries for accurate decision-making and root cause identification. When any abnormality, defect, breakdown, or customer complaint appears, leaders instruct teams to “Go to the Gemba and … Read more