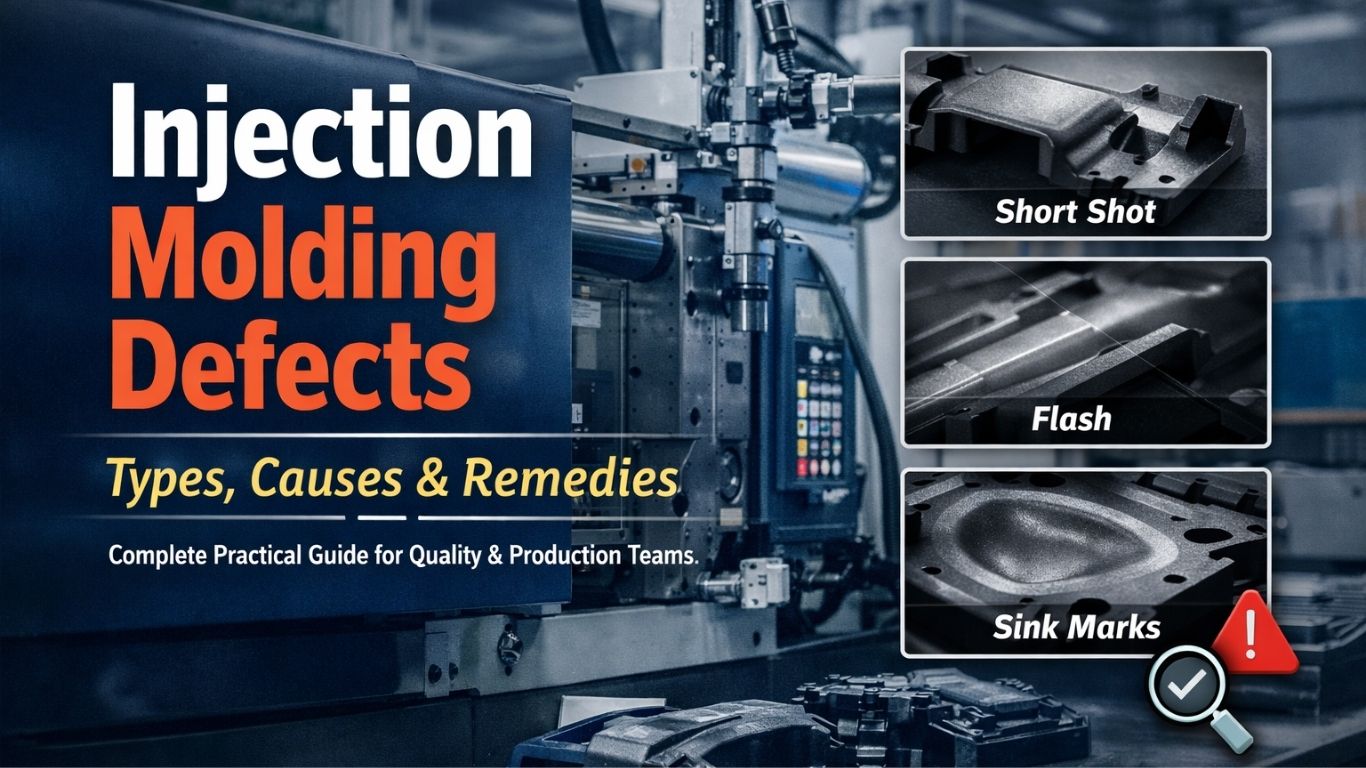

Injection Molding Defects: Types, Causes & Remedies

Injection molding is one of the most widely used manufacturing processes in the automotive, electrical, electronics, and consumer goods industries. Despite advanced machines and automation, molding defects remain a major source of rejection, rework, customer complaints, and audit non-conformities. In quality systems like ISO 9001 and IATF 16949, effective control of molding defects is directly … Read more