Quality Control

Quality control is a process employed to ensure a certain level of quality in a product or service. It includes which actions an organization takes to control and verify certain characteristics of a product or service. The basic goal of quality control is to ensure that the product is as per customer drawing and fulfills customer requirements.

- Quality Control

- Quality Control definition:

- The objective of Quality Control:

- Misconception about Quality Control:

- Quality Control Planning:

- Feedback Control Loop:

- Type of Quality Control:

- Self-Control in quality control:

- Control Stations in quality control:

- How to involve top management in Quality Control?

- 7 QC Tools:

Quality Control definition:

Below is the other definition of quality control:

- Operational techniques and activities for sustaining quality that satisfies given customer needs.

- Operational techniques and activities for monitoring and elimination of causes of unsatisfactory performance at the economic overall cost.

- Activities for ensuring conformance of a product/service to specification and its fitment for the intended use.

- An integrated system for development, maintenance and improvement of quality effort by various groups to ensure delivery of customer satisfaction at an economic cost.

- Quality Control is a system that is used to maintain a desired level of quality in a product or service.

The objective of Quality Control:

- Ensuring conformance to standard during manufacturing and product delivery.

- Quality evaluation of incoming materials bought out parts (BOP) and work in process (WIP).

- Reducing scrap, rework & other losses.

- Reducing inspection costs and customer complaints.

- Saving in material, labor costs and improving productivity.

Misconception about Quality Control:

- If we are making a profit, we do not need to do anything like quality control and only EOL “end of line inspection”/ PDI is sufficient to ensure quality.

- QC is making standards, procedures etc.

- It is something that is applicable only to the manufacturing process and has nothing to do with other functions.

- QC is applying statistics and studying something typical process.

Quality Control Planning:

Planning for Quality Control means designing a control system that includes concepts, methodologies and tools to control operating processes and produce products per customer requirements. The main customers for the control system are the people engaged in Quality Control. People have to be made to understand the quality needs of both internal and external customers.

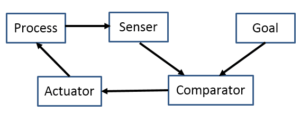

Feedback Control Loop:

Whatever may be the control subject or control feature, the feedback loop plays a vital role in ensuring its conformance to requirements. The feedback process is explained as below:

- The sensor picks up the actual control performance.

- The sensor reports actual performance to the comparator.

- The comparator receives desired standard or goal.

- Comparator compares the actual with standard and if a difference is found, provide corresponding correction signal to the actuator.

- The actuator activates the human or technological processes.

- Process reacts to restore conformance to the standard.

Common examples of control loops are:

- Thermostat to control the temperature of a car engine.

- Governors to prevent overspeeding of the buses.

- Mechanical Circuit Breaker (MCB) and Alarms.

The design and operation of a feedback control loop consisting of the following steps:

- Select-control subject

- Select the appropriate unit of measurement

- Establish the standard of performance

- Select measuring devices/sensors.

- Decide the frequency of measurement

- Measure actual performance

- Compare the measurement with standard

- Take appropriate action

Type of Quality Control:

Automatic Control: Automatic Control is on a real-time basis without any use of operators. for example Thermostat in a refrigerator.

Control by Operators: Operators develop a sense of process ownership and the shortening of the feedback loop speeds reactions. Process control is better and costs get reduced. An operator can adjust the machine to bring meaningful value to the desired point.

Managerial Control: Decision-making is distributed between various levels: Top, middle and lower levels. The lower level takes most of the load. But top management takes vital decisions.

Self-Control in quality control:

A person is said to be in a state of self-control when work is organized to enable a person to have complete mastery over the achievement of planned results and goals. In other words, in self-control planning and execution are done by the same person. Self-control means each employee should have sufficient knowledge of:

- What is expected of him?

- What is his actual performance?

- What are the means to regulate performance if he is failing to meet goals?

To exercise self-control the operator gets additional responsibilities of planning Quality Control, sensing, comparing and decision making.

Control Stations in quality control:

A control station is an area in which control takes place. At the lower level, it is confined to a limited physical area. It is always useful to establish a limited number of control stations in the supply chain. The objective of the control station is to provide evaluation / early warning. Control Stations are usually located at the following points:

- Incoming stores

- Process startup

- Critical product under processing

- Processes involving tool and die wear where periodic re-adjustment is essential.

How to involve top management in Quality Control?

- Talk to top management in the language they understand better. i.e. language of money.

- Take quality objectives seriously. It is very important to stick to the quality objectives set by the top management.

- Incorporate quality management into strategic and tactical planning.

- Ensure the quality performance indicators are an integral part of the performance review. This could be made possible if we make quality activities part of the management review meeting.

You may like to know the difference between quality control and quality assurance.

7 QC Tools:

These are the 7 QC tools which are also called quality improvement tools.